This laser cutter is virtually plug-and-play, and easy to use, with a simple operating interface that allows for customization of cutting parameter settings. The included software is easy to setup with a short learning curve, making it perfect for beginners. The defect of CO2 glass laser tube is the lack of ability to cut through metal, but the cons cannot cover up its pros in cutting non-metallic materials. For my own business, the STJ1390-2 is an excellent laser cutting tool for making precise cuts on most papers as well as wood and acrylic. The high-precision CO2 laser ensures that every cut is crisp and clean, even on intricate designs. Overall, the STJ1390-2 is an efficient laser for most paper cuts, saving you time and money.

Dual-Head CO2 Laser Cutter for Paper and Cardboard

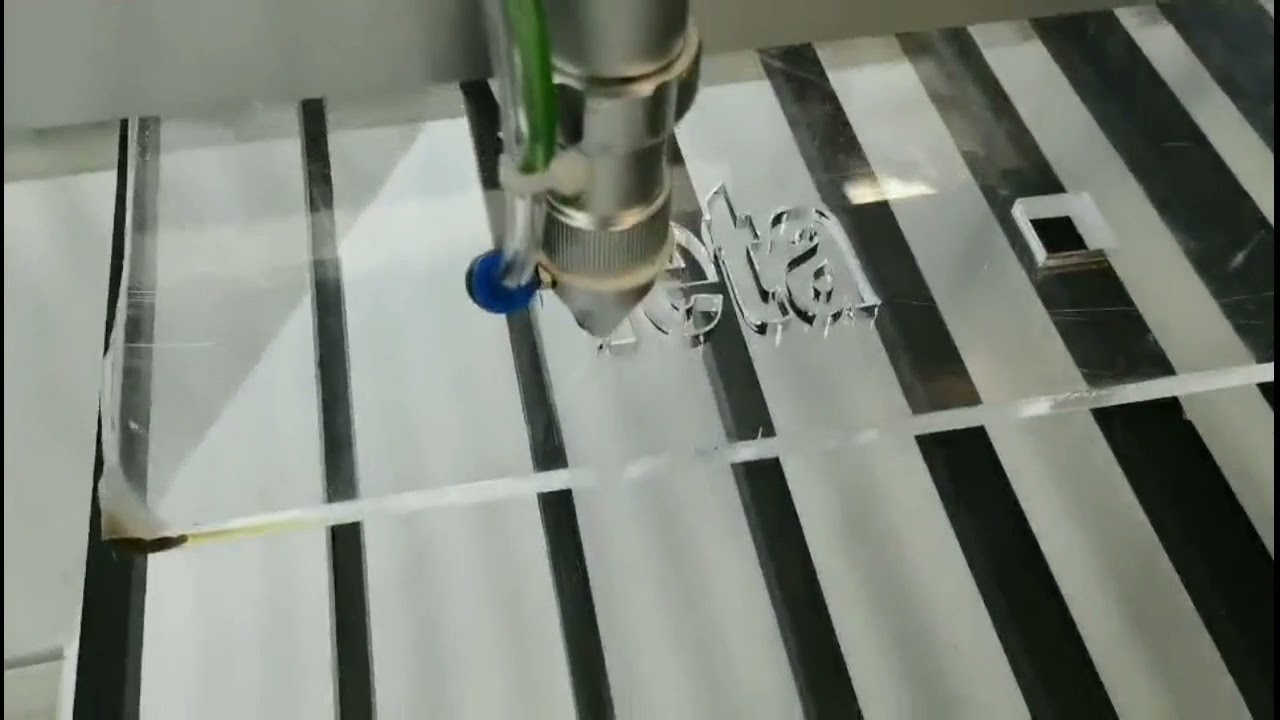

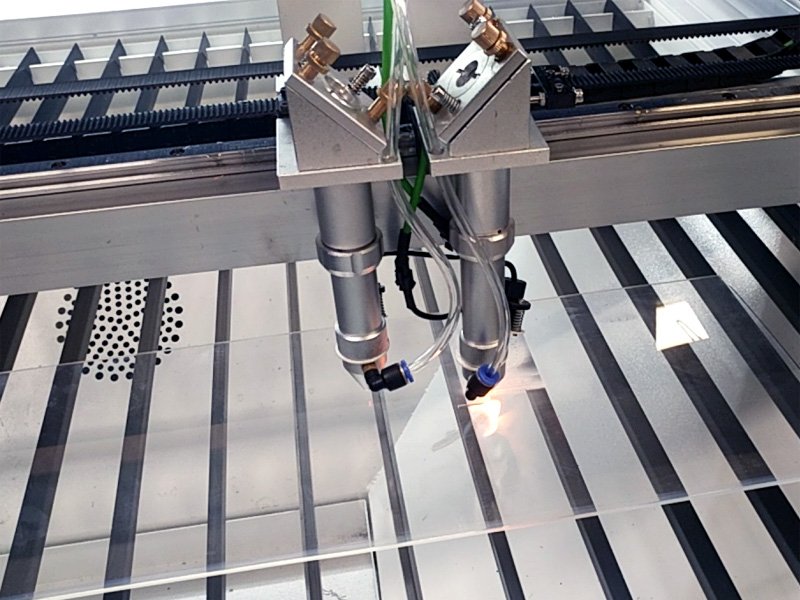

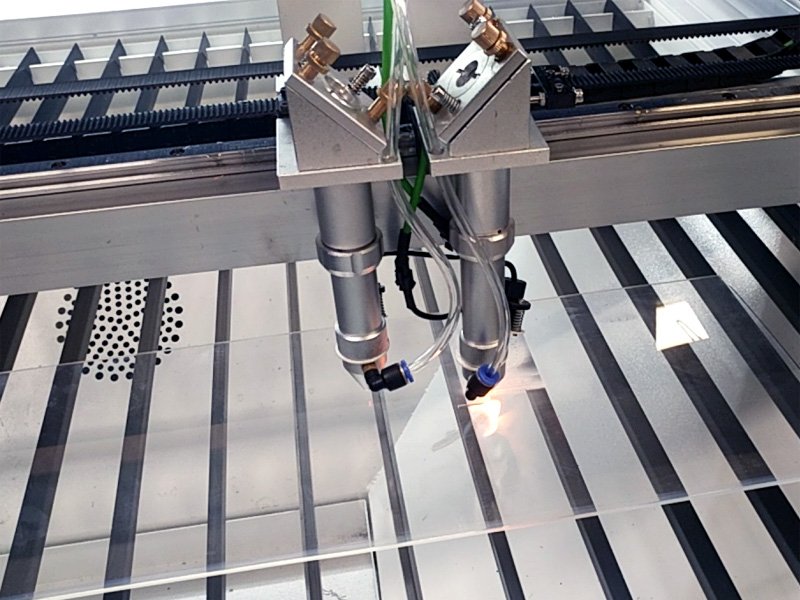

STJ1390-2 dual head CO2 laser cutter comes with double laser cutting heads to cut two projects with paper, cardstock, stacked and layered cardboard at the same time for creating personalized invitations, business cards, arts, crafts, sculptures, mockups, and storage boxes. It is easy to use for both beginners and experts.

- Brand - STYLECNC

- Model - STJ1390-2

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 1300mm x 900mm

- Category - CO2 Laser Cutting Machine

- Laser Source - Yongli, RECI

- Power Option - 80W - 300W

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

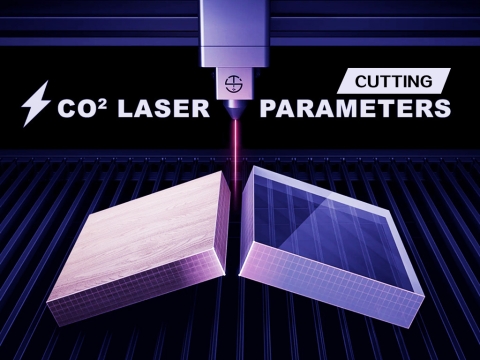

Can A Laser Cutter Cut Through Paper?

Lasers can easily cut through a variety of papers including cultural paper (writing paper, printing paper, newsprint paper), wrapping paper, tissue paper, coated paper, offset paper, composite paper, corrugated cardboard, and some specialty papers, as well as scratch and punch papers to custom personalized invitations, greeting cards, signage, architectural models, and packaging prototypes.

Why Choose Laser To Cut Paper?

The laser cutter is the premier paper-cutting tool to create precise and clean paper-cutting edges. The laser enables high-precision shapes and outlines, and the paper will not burn during the laser-cutting process but rather evaporate suddenly. The cutting edge is virtually unaffected by heat, resulting in the paper remaining smoke-free even with fine contours.

What is a Laser Paper Cutter?

A laser paper cutting machine is a type of CO2 laser cutting system for CCNB (clay-coated news backboard), FBB (folding box board), solid bleached sulfate (SBS), coated unbleached kraft (CUK), coated recycled paperboard, and non-bending chipboard.

Because paper is thinner than most materials and is easier to cut through, we will set the cutting speed very fast to improve work efficiency.

When cutting paper, we often set the cutting speed very fast, so to ensure that the graphics can be completely cut through, we will set the value of the maximum power to be much higher than the minimum power.

We all know that paper is an item that very easily catches fire, and its ignition point is extremely low, so to ensure that it will not be burned when cutting, we recommend that you use an air compressor to blow air to achieve the effect of flame retardant.

Hard paper is very suitable for laser cutting. This kind of paper has a hard texture, is not easy to fold, has a high ignition point, is very flat and beautiful, has smooth cuts, no burrs, and the hollow can be completely cut out. The overall effect is good.

Laser-cut paper can be used to make business cards, greeting cards, handicrafts, promotional displays, scrapbooking, packaging, covers, bookmarks, and handbooks.

What is a Laser Cardboard Cutter?

A laser cardboard cutting machine is a type of CNC laser cutter for single-face board, single-wall board, double-wall board, triple-wall board, corrugated fiberboard, honeycomb cardboard, paperboard, grey paperboard, grey cardboard, matboard, standard matboard, and conservation board.

Paperboard is a broad term commonly used to identify any type of multilayer paper product. This construction typically involves the use of adhesives to bond several paper products together, creating a relatively strong material. Cardboard can be used to make everything from simple storage boxes to home decor items.

When most people think of cardboard, they think of corrugated cardboard for shipping. This type of design involves gluing 2 or more flat sheets to a paper filler with a corrugated or gut design. The result is a cardboard that is very smooth on both sides but has extra strength due to the inclusion of a corrugated midsection. Shipping boxes and case sleeves typically use this cardboard.

Simpler forms are used to create boxes that are ideal as gift boxes. These products usually consist of only one or 2 sheets of thin cardboard. Therefore, these usable boxes are not suitable for transporting goods or for long-term storage. Often these can be folded flat for convenient storage between uses.

Cardboard can also be used to make home decor items. Small boxes used on desks and shelves often use thicker sheet combinations than gift boxes but lack the corrugated design of shipping boxes. Often, decorative boxes come with intricate designs and a range of colors that make them look like metal or wood. In addition to decorative boxes, the same method can be used to make charging pads, decorative picture frames, and even lightw8 book heads.

Thick cardboard can also be used to make mock furniture. Using corrugated or multi-layered cardboard, chairs, tables, beds, and other furniture can be made for use in model homes. This method is great for anyone selling a vacant home because it helps potential buyers understand how to use the rooms without requiring the homeowner to leave behind precious items or temporarily rent furniture for an open house.

Cardboard is used for a variety of purposes. From wrapping materials to gift wrapping needs to mock-up furniture, it provides a simple but useful solution for many different needs. Best of all, it can be constructed from recycled paper, which has a much lower environmental impact than many other modern materials.

Features & Advantages of Dual Head Entry Level CO2 Laser Cutter for Paper & Cardboard

1. Taiwan HIWIN square linear guide rail installed on X Y axis, make sure the works stably and precisely.

2. Professional manufacturers adopt square tube frameworks in China, with more than 40% higher fuselage strength than iron sheet structures. This design prevents the machine from quivering, resonance, and distortion during long-term work.

3. New-style high-efficiency laser tube is adopted. The laser beam is more stable than the traditional type. Usage age is more than 10000 hours.

4. A red dot position system is added to the standard configuration, contributing to a simple and precise working position.

5. Advanced LCD Screen+ USB port+ Offline Control, with professional motion control chip, has the function of consecutively high-speed curve cutting and the shortest path selection, which largely improves your working efficiency.

6. A USB offline control system makes the operation more convenient and faster.

7. An automatic up-down table can be chosen for thick materials and high objects.

Applications of Dual Head Entry Level CO2 Laser Cutter for Paper & Cardboard

Applicable Industries: Applied to boxes, invitations, cards, sculptures, storages, cloth, toys, computer embroidery, models, arts, and crafts, advertising, building, decorations, packaging and printing, and paper products.

Applicable Materials: Available for engraving and cutting paper, cardboard, cardstock, acrylic, ABS, rubber, plastic, fabric, leather, wool, crystal, glass, ceramic tile, jade, bamboo & wood products.

Technical Parameters of Dual Head Entry Level CO2 Laser Cutter for Paper & Cardboard

| Model | STJ1390-2 |

| Working area | 1300mm*900mm |

| Laser power | 80W (300W, 220W,150W,130W,100W for option) |

| Laser type | CO2 sealed laser tube, water-cooled |

| Driving system | Stepper motor |

| Transmission | Belt transmission |

| Guideway | Taiwan Hiwin Square guide rails |

| Control system | Ruida control system RD6445 |

| Lens and mirrors | 3pcs mirrors and 1pcs lens from Singapore |

| Working table | Blade table or Honeycomb table for option |

| Water chiller | Included |

| Engraving speed | 0-7500mm/min (According to the materials) |

| Cutting speed | 0-4000mm/min (According to the materials) |

| Power supply | 220V/50HZ , 110V/60HZ |

| Graphic format supported | BMP, PLT, DST, DXF, AI |

| Software supported | CorelDraw, PhotoShop, AutoCAD, TAJIMA |

| Up-down worktable | Optional |

| Autofocus | Optional |

| Red pointer | Yes |

| Optional parts | Rotary device |

| CCD camera |

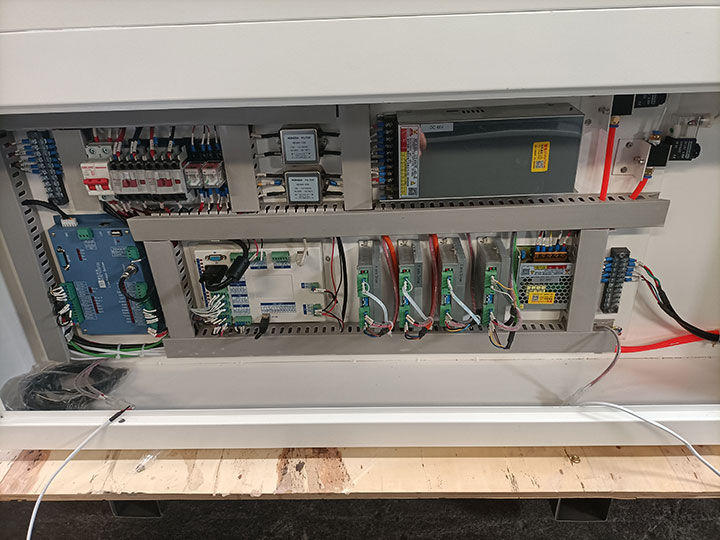

Entry Level Dual Head CO2 Laser Paper & Cardboard Cutting Machine Details

Entry Level Dual Head CO2 Laser Cutting Machine for Paper & Cardboard Projects

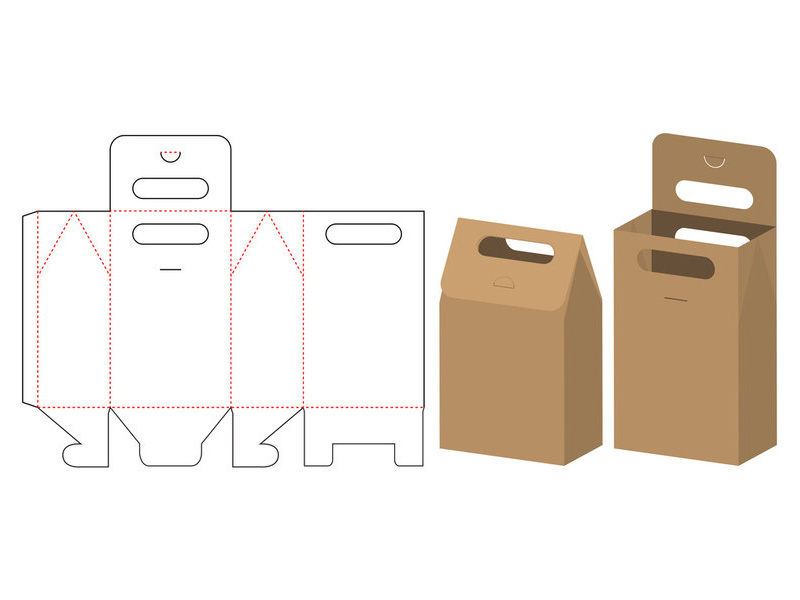

Laser Cut Cardboard Boxes

Laser Cut Paper Projects

Laser Cut Paper Business Cards

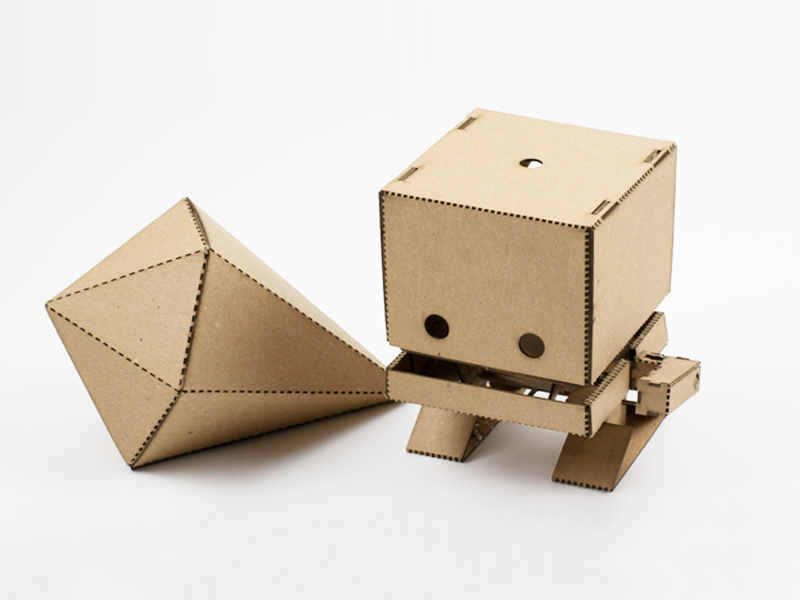

Laser Cut Cardboard Projects

Entry Level Dual Head Laser Cut Projects

Package of Entry Level Dual Head CO2 Laser for Paper & Cardboard Cutting Machine

How Laser Cutters Reduce Waste in Paper and Cardboard Processing?

Laser cutters are revolutionizing the way industries handle paper and cardboard by significantly reducing waste. Their precision and efficiency make them a game-changer in manufacturing, especially for businesses focused on sustainability. Let’s explore how laser cutters are helping reduce waste in the paper and cardboard processing industry.

Precision Cutting Minimizes Scrap

Because laser cutters are so precise, every cut is made precisely to the required measurements. This precision reduces the chances of excess material being cut, which minimizes scrap and waste. With laser cutting, businesses can maximize the use of each sheet of paper or cardboard, cutting down on material waste.

Customization Without Excess Material

Laser cutters are highly versatile, allowing for intricate and custom designs to be produced. Whether it’s a unique shape or a detailed pattern, the machine can cut precisely according to the design, ensuring that no material is wasted. Traditional methods may result in unwanted offcuts, but laser cutting uses every inch of the material effectively.

Faster Turnaround Times

With their speed and efficiency, laser cutters can process paper and cardboard at a much faster rate than traditional cutting methods. Faster cutting reduces the overall material handling time and minimizes the chance of human error. Additionally, high-speed operations mean less material is exposed to the cutting process, reducing waste from errors or slow processes.

Reduced Need for Multiple Passes

Unlike traditional cutting methods, laser cutters typically require fewer passes to achieve the desired result. Each cut is made with precision in a single pass, which not only reduces the time required for production but also minimizes material waste. This ensures that the material’s integrity is maintained while achieving the final design.

Eco-Friendly Production

Laser cutting is a cleaner process compared to other methods, generating less pollution and fewer byproducts. By reducing material waste and minimizing the need for other resources like adhesives or cutting oils, businesses can achieve more sustainable, eco-friendly production practices.