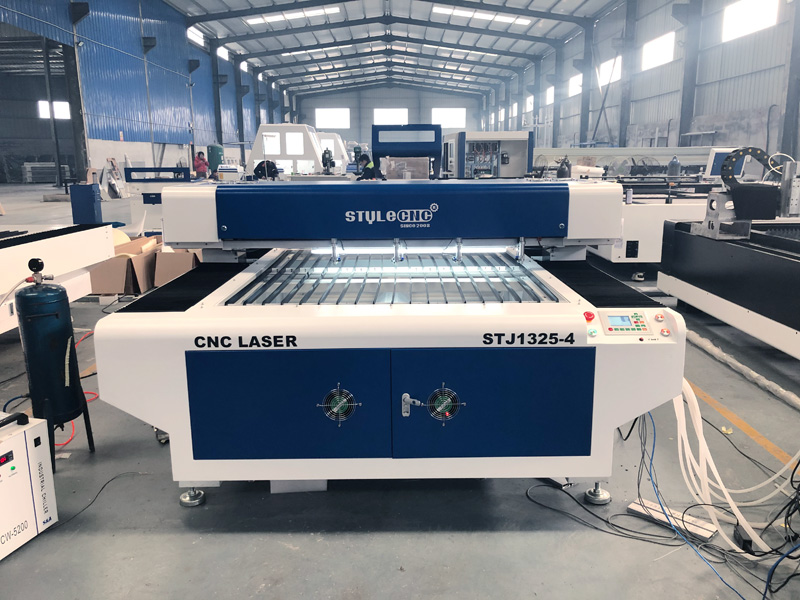

I have been looking for a powerful laser cutter to create personalized plywood crafts and decors for my home business, but it turns out to be hard to find a laser capable of batch cutting. I found this multi-head laser at STYLECNC and got it 15 days later. Almost plug and play except for the assembly of laser tube and chiller. Remote software debugging makes operation easy. I'm new to lasers and it took me a few days to learn how to use it. I cut my first project today and had a lot of fun. Hope to try out more features later.

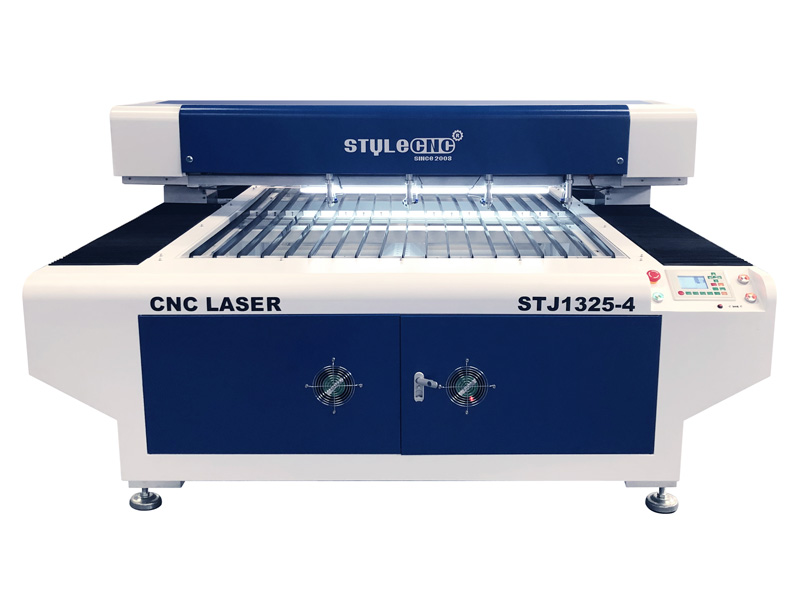

2025 Best-Selling 4x8 Laser Cutter for Plywood & MDF

2025 best-selling affordable 4x8 laser cutter with four laser heads can cut a full sheet of plywood or MDF to make multiple boxes, decorations, gifts, furniture, artworks, crafts, and more projects from 1 up to 4 at the same time. Now the full-size 4x8 laser MDF & plywood cutting machine for sale at cost price.

- Brand - STYLECNC

- Model - STJ1325-4

- Maker - Jinan Style Machinery Co., Ltd.

- Sizing - 4' x 8' (48" x 96", 1300mm x 2500mm)

- Category - CO2 Laser Cutting Machine

- Laser Source - Yongli, RECI, SLW

- Power Option - 150W - 600W

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What is a Plywood Laser Cutter?

A laser plywood cutting machine is a type of automatic laser wood cutting system for hardwood plywood, softwood plywood, flexible plywood, aircraft plywood, marine plywood, tropical plywood, decorative plywood (overlaid plywood), and other plywood.

Plywood is a three-layer or multi-layer board-like material that is made of wood segments into veneers or sliced into veneers, and then glued with adhesives. The fiber directions are glued perpendicular to each other.

Plywood is one of the most commonly used materials for furniture. It is one of the three major wood-based panels. It can also be used for aircraft, ships, trains, automobiles, buildings, and packaging boxes. A group of veneers is usually formed by gluing the adjacent layers of wood grains perpendicular to each other. Usually, the surface plate and the inner layer are symmetrically arranged on both sides of the center layer or the core. It is a slab made of glued veneers crisscrossed in the direction of the wood grain and pressed under the condition of heating or no heating. The number of layers is generally odd, and a few are even. The physical and mechanical properties in the vertical and horizontal directions are slightly different. Commonly used plywood types are three plywood, five plywood, and so on. Plywood can improve the utilization rate of wood and is a main way to save wood.

The usual length and width specifications are: 1220×2440mm, while the thickness specifications are generally: 3mm, 5mm, 9mm, 12mm, 15mm, 18mm, and more. The main tree species are beech, camphor, willow, poplar, eucalyptus, and so on.

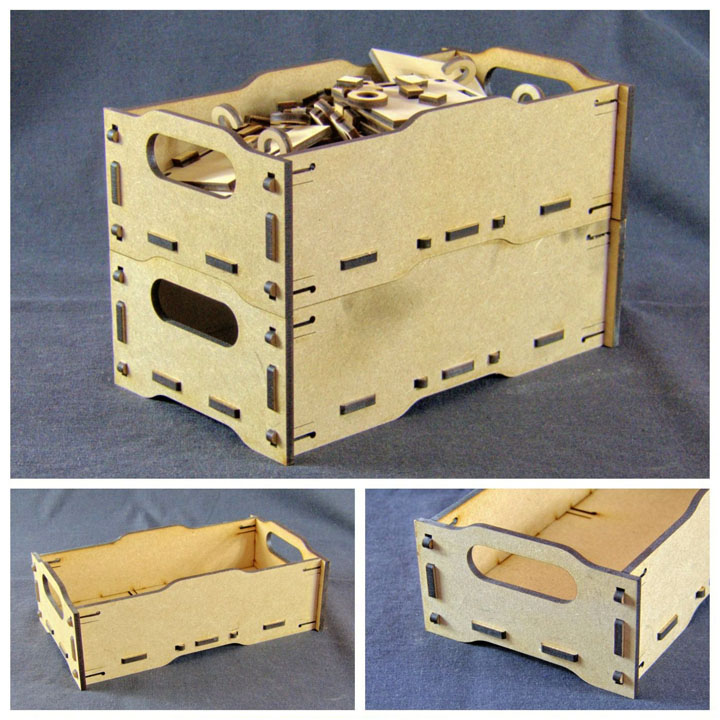

With a laser plywood cutter, you can cut and engrave toys, arts, and crafts, souvenirs, Christmas ornaments, gifts, architectural models, and more. The laser can cut any plywood shape to create the look you like and can cut thicknesses up to 20mm.

What is an MDF Laser Cutter?

A laser MDF cutting machine is a type of wood laser cutter for regular MDF, MDF ultra lite, colored MDF, moisture resistant MDF, no added formaldehyde (NAF), fire-rated MDF, exterior grade MDF, particle board, fiberboard, and laminated board.

MDF stands for medium-density fiberboard, MDF is made of wood fiber or other plant fiber as raw material, applied with urea-formaldehyde resin or other synthetic resin, and pressed under heating and pressure conditions to form a board with a density in the range of 0.50 ~ 0.88g/cm3. Other suitable additives can be added to improve sheet properties. MDF has good physical and mechanical properties and processing properties and can be made into boards of different thicknesses, so it is widely used in furniture manufacturing, construction, and interior decoration. MDF is a homogeneous porous material with good acoustic properties and is a good material for making speakers, TV casings, and musical instruments. In addition, it can also be used for ships, vehicles, sports equipment, floors, wall panels, partitions, etc. instead of natural wood. It has the characteristics of low cost, simple processing, high utilization rate, and more economical than natural wood.

Applications of 2025 Best-Selling 4x8 Laser Cutting Machine for Plywood & MDF

Applied Industries

The laser cutter is applied to woodworking, crafts making, arts, gifts, clothing, toys, computer embroidery, mold making, advertising, building decoration, home decoration, paper industries, packaging, and printing.

Applicable Materials

The laser cutting machine is available for engraving and cutting MDF, plywood, bamboo, wood, paper, cardboard, plastic, acrylic, ABS board, rubber, fabric, textile, leather, wool, crystal, glass, ceramic tile, and jade.

Technical Parameters of 2025 Affordable 4x8 Laser Cutter for Plywood & MDF

| Model | STJ1325-4 |

| Table Size | 1300mm*2500mm |

| Laser Power | 150W RECI Brand |

| Laser Type | CO2 sealed laser tube, water-cooled |

| Driving System | 3 phases leadshine brand stepper motor |

| Transmission | Belt transmission |

| Guideway | Taiwan PMI Square guide rails |

| Control System | Ruida control system |

| Lens and Mirrors | 3pcs mirrors and 1pcs lens from America |

| Working Table | Blade table or Honeycomb table for option |

| Red Pointer | Included |

| Engraving Speed | 0-7500mm/min (According to the materials) |

| Cutting Speed | 0-4000mm/min (According to the materials) |

| Power Supply | 220V/50HZ |

| Graphic Format Supported | BMP, PLT, DST, DXF, AI |

| Software Supported | CorelDraw, PhotoShop, AutoCAD, TAJIMA |

| Optional Parts | Up-down worktable |

| Autofocus | |

| Rotary device | |

| CCD camera |

Features of 2025 Best-Selling 4x8 Laser Plywood & MDF Cutting Machine

The CO2 laser cutting system has features of accurate cutting, fast speed, simple operation, personalized cutting process, and accuracy, laser head running track simulation display, multiple path optimization functions, and an automatic typesetting system to ensure the greatest possible saving of materials and cost.

1. New-style high-efficiency RECI laser tube is adopted. A laser beam is more stable than the traditional type. Life span is more than 10,000 hours.

2. Lens and mirrors from the USA with good reflective effect.

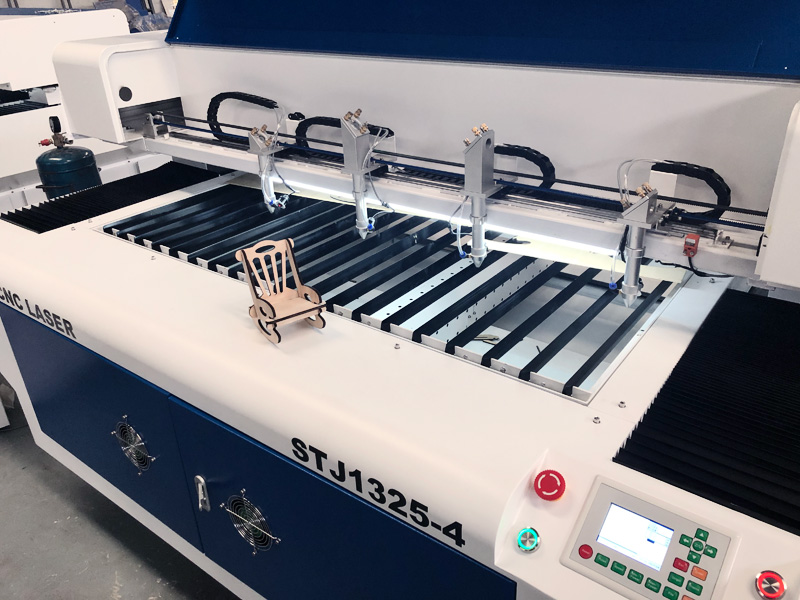

3. Four laser cutting heads with a distance of 30cm. It can cut four same projects at the same time to improve the working efficiency.

4. Double channel exhaust fans to clean the cutting chippings.

5. Taiwan PMI square linear guide rail installed on X Y axis, make sure the works stably and precisely.

6. Leadshine brand stepper motor and driver transmission, no need for feedback signal to control with high precision.

7. Blade working table, It is mainly designed for hard materials cutting, such as plywood, plastic, and MDF. Honeycomb table for soft materials, such as paper, fabric, leather, and rubber.

8. Advanced LCD Screen + USB port + Offline Control, with professional motion control chip, the function of consecutively high-speed curve cutting and the shortest path selection, which will highly improve your working efficiency.

2025 Best-Selling 4x8 Laser Cutting Machine for Plywood & MDF Projects

Laser Engraved & Cut Plywood Projects

Laser Cut MDF Projects

Laser Cut Plywood Projects

Warranty of The Affordable 4x8 Laser Cutting Machine for Plywood & MDF

1. The whole laser cutting machine: one year.

2. Laser tube: 40W for 5 months, 60W for 6 months, RECI 80W, 100W, 130W, 150W for 10 months (this is what laser tube suppliers offer to us).

3. If the accessories are broken because of quality problems during warranty time, we will change them for free.

4. 24-hour technical support online like Skype/WhatsApp/remote, you can call us if urgent.

5. We offer free training in our factory, and our engineers are available to service overseas, but the round-trip air tickets, hotel, and meals for the engineers should be paid for by our buyer.

We also have CO2 laser cutters for MDF and plywood with more table sizes, including 600 mm*400 mm, 900 mm*600 mm, and 1300 mm*900 mm.

STJ6040 Desktop Laser Cutter for MDF, Plywood

STJ9060 Hobby Laser Cutter for Plywood, MDF

STJ1390 Best Laser Cutter for Plywood, MDF

Buying Considerations!

Buying an affordable laser cutter for plywood and MDF can be tricky. Considering a few important factors can make your decision easy. These are,

1. Material Compatibility: Consider the thickness of the plywood and make sure the cutter can cut MDF effectively.

2. Laser Power: A diode laser with at least 10W power output is recommended. The material type, laser speed, and beam size can also impact cutting quality.

3. Engraving Area: A 4x8-foot (48" x 96") bed size is common for industrial applications. But a larger bed allows you to work with bigger sheets of plywood or MDF.

4. Software Compatibility: Make sure that the laser cutter’s software is compatible with your design software.

5. Safety Features: Ensure working emergency stop buttons, enclosure interlocks, and proper ventilation.

6. Brand Reputation: Choose a reliable supplier and consider after-sales service.

FAQs for The Most Popular 4x8 Laser MDF & Plywood Cutting Machine of 2025

What is MDF?

MDF is the English acronym for medium-density fiberboard. It is made of hardwood, softwood fibers, or other plant fibers as pigments. After being broken, separated, dried, and then applied with urea-formaldehyde resin or other suitable adhesives, it is made by hot pressing. artificial board. MDF (Medium Density Fibreboard) is usually denser than plywood, and although it is composed of separate fibers, it can be used as a building material like plywood. In addition, it is stronger and denser than the scarf board.

Medium-density fibreboard (MDF) is available in a variety of sizes and thicknesses, and laser cutting MDF is easy and smooth without breaking or cracking. Its edges and surfaces can be made into a variety of deeply etched galleries, and the mirror-smooth surface is ideal for painting, gluing, laminating, texture printing, and coloring. Some manufacturers can provide a series of different types of medium-density fiberboard (MDF), including standard, flame retardant, moisture-resistant, outdoor, and high-density. These properties are not affected by laser cutting or machining. This fiberboard has the above characteristics and advantages, making it an ideal wood-based panel material for many industries, such as furniture, construction, signage, and shop decoration.

What MDF can a laser cut?

• Indoor medium-density fiberboard, with the symbol MDF, is a medium-density fiberboard that does not have the effect of short-term water immersion or high humidity. Its color identification is the natural color.

• Indoor moisture-proof medium-density fiberboard, with the symbol MDF.H, is a medium-density fiberboard that can withstand short-term cold water immersion or high humidity, suitable for indoor kitchens, bathrooms, and other environments. Its color identification is green.

• Outdoor medium-density fiberboard, with the symbol MDF.E, is a medium-density fiberboard that can withstand the aging effect of climatic conditions, water immersion, or water vapor damp heat in ventilated places. Its color identification is gray.

What is plywood?

Plywood refers to a wooden board composed of multiple layers of veneer, which are glued together. Each veneer or veneer is bonded with its grain at right angles to adjacent layers, creating strength and durability. Plywood is probably the most popular and versatile man-made woodworking material for homes today. It is a laminated product consisting of many thin strips of wood laid in alternating directions and glued together to form a strong, stable sheet.

What types of plywood can a laser cut?

• Cork plywood - This is the most widely used plywood creation and consists of cork veneer, usually fir. The sheets are held at right angles to each other and glued together.

• Hardwood plywood - Most commonly used in furniture and cabinets, it has a smooth, attractive finish with a clean finish.

• Decorative plywood - Also known as overlapping plywood, generally made from oak, ash, red oak, maple, birch, and mahogany.

• Aircraft plywood - This category is known for its strength. It can also be made of spruce, mahogany, or birch; however, its distinguishing feature is that it is not affected by heat.

• Tropical plywood - It is a plywood made by mixing different varieties of wood or wood from the tropics. It is known for its special qualities such as density, strength, uniformity, abrasion resistance, rigidity, and thickness.

• Marine plywood - The variety of plywood that can be used in wet, humid, and humid environments is called marine plywood and can be used for a long time.

• Flexible plywood - It is a type of plywood used for flexible or bendable structures or furniture. Furniture today is often curved or curved structures.

Can a laser cut through MDF?

A laser cutting machine can easily cut through MDF. However, due to the different materials of MDF, not every MDF can be cut with a laser machine. Some MDFs contain too much iron scraps, soil, and other impurities, and are not suitable for laser cutting. In addition, some MDF itself is not dense enough and is not suitable. At present, the types of MDF that can be cut by the laser cutting machine include Aosong board, poplar board, washed board, and so on. Among them, the Osong board is the best.

How thick MDF can a laser cut?

The thickness of the laser cutting MDF is related to the power of the laser. The higher the laser power, the thicker the MDF can be cut. Commonly used MDF thickness is 6mm, 12mm, 18mm, and so on.

What is the speed of laser cutting MDF?

• The thickness of the laser-cutting MDF is related to the laser power and the thickness of the plate. The higher the power of the same MDF laser cutting the same thickness, the faster the cutting speed.

• 150W CO2 laser cutting 12mm Osson board at a speed of 7mm-12mm per second.

• The 280-watt CO2 laser cuts 12mm Aosong board at a speed of 16mm-25mm per second; the 1000W CO2 laser cuts 12mm Aosong board at a speed of 20mm-40mm per second.

What is the line drawing speed?

The speed of the laser cutting machine's line drawing is related to the structure of the machine itself. Generally speaking, it is between 100 mm and 500 mm per second. There are some limitations of the mechanical structure of the machine itself, and the line speed and idle speed may be limited to less than 100 mm per second.

What does the width of the cutting gap depend on?

It is related to the size of the laser spot and the focal length of the focusing lens itself, and it is also related to whether the cutting surface is in focus. The larger the laser power, the larger the light spot and the larger the cutting gap. Which power is the most suitable, we have done a detailed comparison and research on this point, and you can contact customer service for consultation.

What does the thickness of the drawn line matter?

It is related to the laser power, the focal length of the focusing mirror, whether it is in focus, the laser brand, and more.

Why are the line drawings uneven in thickness?

One case is that the platform of the machine itself is not flat or the plate to be cut is not flat, resulting in a change in the height of the laser head from the cutting surface. Another kind of laser itself has unstable power, and the light is weak and strong.

Why can MDF be cut through in some places but not in others?

This situation generally occurs on low-power laser-cutting machines. When the 150-watt carbon dioxide laser cuts MDF, if the optical path is not adjusted or the machine platform is not leveled, this will happen. In addition, the power of the laser will drop after a period of use. This will also happen.

Why is the laser-cut MDF black and loses powder severely when rubbed?

It has something to do with the MDF material. It is recommended to change the Aosong board or other materials to try. When laser cutting Aosong board, not only the cutting speed is fast, but the density of the MDF itself is high. After laser burning, the surface oil will form a natural protective film. The surface is easy to wipe and moisture-resistant.

Why are there small holes on the surface of laser cut MDF?

The density of the MDF board itself is low.

Why can't laser cutting MDF vertically?

• The optical path needs to be re-adjusted.

• The cutting table surface is uneven, re-level it.

Why can't the laser cut through the MDF and there is sticking at the bottom?

• The power of the laser generator decreases after being used for a long time and needs to be replaced.

• The optical path is not adjusted properly and needs to be readjusted.

• The MDF material is defective.

• The laser cutting table is re-leveled.

Billy Sanchez

Tim

I'm a craftsman, with this machine, I made a lot of MDF crafts, and the STJ1325-4 is professional for the edge cuts of wood. Perfect laser for my business.