Nesting CNC Wood Cutting Machine for Custom Furniture Maker

Nesting CNC wood cutting machine is an automatic cutter for personalizing modern furniture and decors to save space and beautify your home and office style.

- Brand - STYLECNC

- Model - S4

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Advantages of Nesting CNC Wood Cutting Machine for Custom Furniture Maker

1. Highly automated nesting cnc router machine with automatic loading and unloading system. The complete work cycle of loading, nesting, drilling and unloading is carried out automatically, which results in maximum productivity and zero down time.

2. Humanizing design of the machine control interface,very simple to operate, requiring only minimal training of operator, do not need specialized operation technical personnel, high efficiency.

3. First class components--ATC spindle, Taiwan LNC control system, 1500W servo motors and drivers, high precision planetary gear reducers, etc,stable performance and long service life.

4. Strong 7.5KW vacuum pump and table, high adsorption capacity, can be strong adsorption of materials of different sizes, density, no deformation.

5. Truly versatile: nesting, routing, vertical drilling, cutting,side milling and edge grinding all in one. It is well-suited for panel furniture, office furniture, cabinets production.

Features of Nesting CNC Wood Cutting Machine for Custom Furniture Maker

STYLECNC S4 Nesting CNC wood cutting machine with automatic loading and unloading tables. It is capable of handling a wide variety of milling, drilling, contouring, boring, shaping, grooving, routing and engraving projects, it also choose auto labeling device to be S6 model.

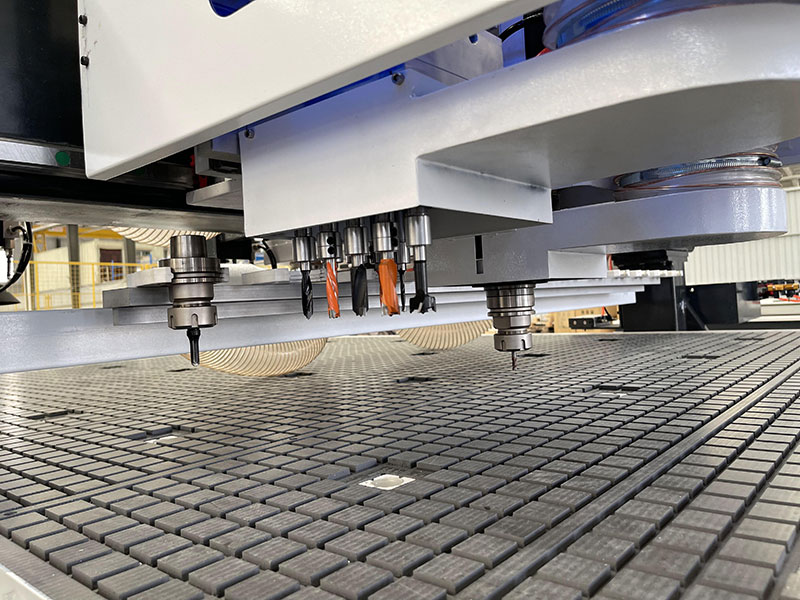

9KW ATC spindle with vertical drilling bank.

Positioning pop-up pins and tool sensor:

There are 2pcs on Xaxis, 3pcs on Y axis for easy loading and alignment of materials.

Tool sensor can greatly reduce the errors caused by inaccurate tool calibration, tool breakage due to manual operation.

With auto loading unloading table, can save a lot of labor for working.

Taiwan LNC control system, break point memory, continuing carving after power outage, forecasting processing time.

Dust collector, make the work environment dust-free.

Applications of CNC Nesting Wood Cutter for Modern Furniture & Home Decor

1. Furniture industries: cabinet doors, wooden doors, solid woods, plates, antique furniture, doors, windows, desks and chairs.

2. Decoration industries: screens, wave boards, large-size wall hangings, advertising boards and sign making.

3. Arts & Crafts industries: Engrave on artificial stones, woods, bamboos, marbles, organic boards, double-color boards and so on for achieveing effects of exquisite patterns and characters.

4. Processing material: engraving, milling and cutting processing for acrylic, PVC, density boards, artificial stones, organic glass, plastics and soft metal sheets such as copper and aluminum.

5. Suitable for compound processing pattern milling, sawing and drilling. It belongs to the price and high-efficiency machining equipment.

6. Slab countertops can do the whole board adsorotion processing directly without the preparation of material cutting.

7. The machine's drilling pattern is multi-function drilling. It is equipped with any arrangement combination of vertical drilling, side drilling, single drilling and group drilling, etc.

8. Suitable for processing display counters, artifical stone flow management units, petrochemical PF filter plates, headboard, insulation plates, styrofoam model, yacht bedroom, OA office desktop.

Technical Parameters of CNC Nesting Wood Cutter

| Model | S4 |

| Table size | 1300mmX2500mmX300mm |

| Repositioning resolution | ±0.02mm |

| Max running speed | 50m/min |

| Max cutting speed | 30m/min |

| Tool magazine | Linear Type 12 tools |

| Working voltage | 380V/3 Phase/50HZ or 220V/3 Phase/Single phase/60HZ |

| Spindle | 9.0KW HQD air cooling |

| Spindle speed | 24000r/min |

| Driving system | Leadshine servo motor and drivers 1500W |

| Software | Artcam |

Optional Items for CNC Nesting Wood Cutter

| Spindle | 9.0KW HSD HSK-F63/ISO30 |

| Table Design | Vacuum&T-slot table combined |

| Vacuum Pump | 2.2KW with single phase |

| Hold Down System | Pressure rollers following with spindle for a hold-down on the workpiece |

| Driving System | Yaskawa servo motors |

| Operation System | Syntec, Weihong,etc |

| Pneumatic drill | 5+4 drilling bank |

| Tool magazine | Disc tool changer 12 tools |

| Protection Device | laser light curtain |

Nesting CNC Wood Cutting Machine for Custom Furniture Making Projects