Low Cost Industrial CNC Router Machine for Sale

Low cost industrial CNC router machine STM2030 is used for industrial manufacturing of 2D/3D flatbed carving & cutting in woodworking, arts & crafts, decorations, cabinet making, door making, furniture making, acrylic, plastic, foam, aluminum, copper, and glass. Now the cheap industrial CNC machine for sale at affordable price.

- Brand - STYLECNC

- Model - STM2030

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 2000mm x 3000mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

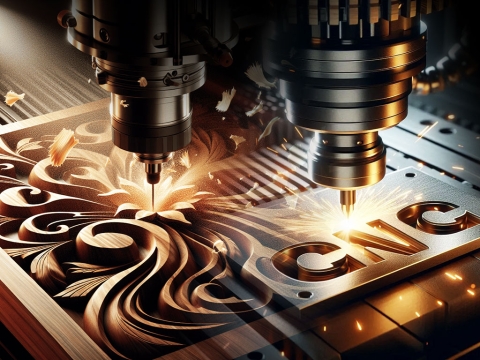

What Is an Industrial CNC Router Machine?

An industrial CNC router machine is a type of large format automatic CNC router table for commercial use in industrial manufacturing, which can easily do flatbed cutting, 2D routing, and 3D relief carving. An industrial CNC router table is made of strong welded tubular steel, which is heavy-duty and stable with high accuracy during machining. A gantry-type industrial CNC machine has powerful functions and multiple applications in one machine, whether furniture making or aluminum cutting, all can be easily completed.

Industrial CNC Router Machine Features

1. Heavy-duty welded tubular steel frame that keeps the lathe bed of an industrial CNC machine in shape.

2. The Y axis of the industrial CNC machine is equipped with double motors to keep it stable moving.

3. Speedy and accurate rack rail travel method.

4. Top brand square linear rail with high accuracy and heavy burthen.

5. Advanced vacuum with double cavities.

6. Humanized design of lathe bed vacuum that is easy to operate.

7. Intelligent protection system that protects the machine from damage resulting from false operation.

Industrial CNC Router Machine Applications

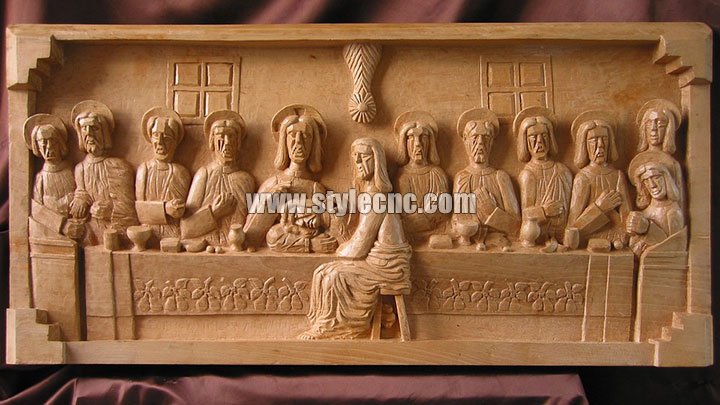

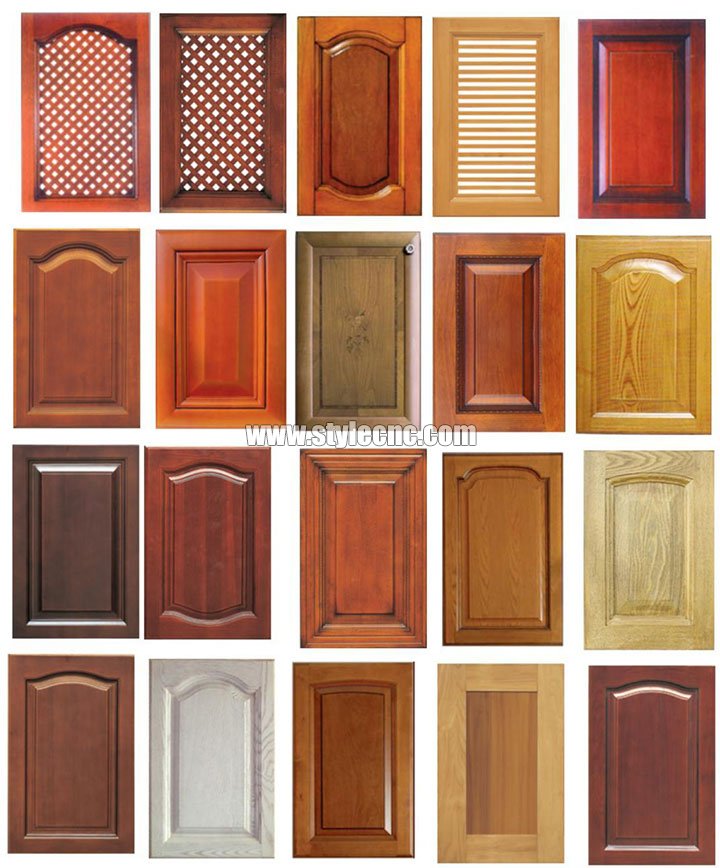

Industrial CNC machines are used for single lines, milling, 2D/3D cutting, and carving in furniture production, advertising, woodworking, decoration, wood artwork, wood crafts, home decoration, office doors, home doors, cabinet doors manufacturing, foam, plastic, acrylic, glass, aluminum cutting, and milling.

This type of machine tool is ideal for:

1. Wood.

2. Timber.

3. MDF.

4. Plastics.

5. Aluminum composite.

6. Soft metals.

7. Acrylic.

8. Foam.

Industrial CNC machines are applied in:

1. Furniture Making: cabinets, panel furniture, office furniture, home furniture, doors, chairs, tables, and windows.

2. Custom Woodworking: Wood arts, wood crafts, voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Plate Processing: Insulation part, ABS, PCB, PP, PE, inner car body, plastic chemical components, bowling tracks, anti-bate board, stairs, epoxy resin, and carbon mixed compounds.

4. Decorations: PVC, MDF, acrylic, plastic, organic glass, artificial stone, and soft metals such as copper, aluminum plate cutting, carving, and milling.

Technical Parameters of Industrial CNC Router Machine

| Model | STM2030 |

| Working Area | 2000*3000*200mm |

| Resolution | ±0.03/300mm |

| Repeatability | ± 0.01mm |

| Lathe Structure | Welded steel frame |

| X/Y Structure | Rack Pinion, Linear Square Rails |

| Z Structure | Taiwan TBI Ball Screw, Linear Square Rails |

| Max. Rapid | 0-32000mm/min |

| Max. Working Speed | 0-20000mm/min |

| Spindle | 3KW Water-Cooling Spindle |

| Spindle Speed | 24000RPM |

| Working Mode | Stepper |

| Working Voltage | Three Phase AC380V/220V, 50HZ/60Hz |

| Command Code | G-code(*uoo,*mmg) |

| Operating System | DSP control system |

| Interface | USB Offline |

| System Memory | 128M (or pen driver) |

| Collet | ER20 |

| X, Y Working Delicacy | <0.02mm |

| Software | Type3, Artcam, Ucancam, Mastercam |

| Running Circumstance | Temperature: 0°C~45°C |

| Relative Humidity: 30%~75% | |

| Packing Size | 3550x2210x1050mm |

| Net Weight | 1350KG |

| Gross Weight | 1650KG |

Option Items

1. Vacuum Table.

2. Working Area.

3. Automatic Tool Changer.

4. Spindle.

Industrial CNC Router Machine Details

Industrial CNC Router Machine Projects

Services & Support for Industrial CNC Machines

Guarantee

One-year warranty for the whole industrial CNC machine. Within 12 months of normal use and maintenance, if something is wrong with the machine, you will get CNC spare parts for free. Out of 12 months, you will get CNC spare parts at a cost price. You will get 24/7 service and technical support in all your lifetime.

After-Sales Service

The industrial CNC machine is properly adjusted before dispatch. You can start to use the machine immediately after receiving it.

Besides, you will be able to get free training advice for the machine in our factory. You will also get free consultations and suggestions, services, and support.

Technical Support

1. Technical support via Email, WhatsApp, Skype, Tel, Live Chat, and Remote Desktop around the clock.

2. Friendly English user manual and CD with operation video.

3. Our Engineer is available to service overseas.

Working Environment

The machine is a high-tech mechatronics equipment, which has certain requirements for the working environment.

1. Avoid strong electricity, strong magnetism, and other equipment that seriously affect the signal transmission of the machine, such as electric welding machine, launch tower, etc.

2. Use a three-core power supply to ensure a good grounding of the machine and reduce interference.

3. The voltage is required to be stable and avoid large fluctuations. It is best to use a voltage stabilizer.

4. The machine should not work for a long time in a strong acid or alkaline environment.

Industrial CNC Machining

1. The Rationality of Machining Technology.

Besides relying on the machine to ensure the machining accuracy, reasonable machining technology is also very important. To ensure the accuracy of machining, please pay attention to the rationality of the machining technology.

2. Tool Use.

The machining accuracy is affected by the manufacturing process and the precision of the tool itself. Therefore, please select a tool suitable for routing.

3. Operators.

The proficiency and sense of responsibility of the operators also have a huge impact on the machining accuracy.

4. Wear and Tear of The Machine.

The machine inevitably wears during use. As time goes by, the machine wear will reduce the accuracy of the machine.

How to Choose the Best Low-Cost Industrial CNC Router

Finding the appropriate industrial CNC router is difficult, especially if you are on a tight budget. A good machine balances affordability with functionality to ensure that you get value for your investment. Following are some of the key factors you must consider while making a decision.

Understand Your Application Needs

Identify the main applications you will be using a router for such as cutting, engravings, or drilling. Mention the types of material to be worked with-wood, metal, or plastic. These requirements will narrow down choices for machines suitable for specific projects. Make sure the machine will be able to handle your needs in case your enterprise requires upgrades or more applications sometime in the future.

Evaluate Cutting Area and Size

Choose a CNC router with a cutting area that matches the size of your typical workpieces. For larger projects, ensure the machine has a spacious working bed. A properly sized machine avoids limitations and enhances productivity. Always measure your available workshop space to accommodate the router comfortably.

Check Build Quality and Durability

Inspect the machine’s construction materials, such as steel or aluminum frames. A sturdy build ensures stability during operation and longer lifespan. Avoid machines that compromise durability for a lower price. Check for vibration-dampening features to maintain cutting accuracy.

Consider Software Compatibility

Ensure the CNC router supports user-friendly and widely-used software for programming. Compatibility with common CAD/CAM software can simplify design and operation, especially for beginners. Look for software that allows easy updates to keep up with evolving technologies.

Assess Customer Support and Warranty

Look for manufacturers offering reliable customer support and a good warranty period. This ensures assistance for troubleshooting and repairs, protecting your investment. Check for online resources, such as tutorials and forums, for quick problem-solving.

Care & Maintenance

Regular maintenance doesn't just keep your machine in good working condition but also helps you get the most out of your investment. By following a few simple steps, you can enjoy smooth operations, reduced downtime, and precise results every time.

Cooling System Maintenance

• Limit continuous operation time to less than 10 hours per day.

• Ensure cooling water remains clean and the water pump functions normally.

• Do not allow the water spindle motor to run without sufficient water.

• Replace cooling water regularly to avoid excessive water temperature.

• Use antifreeze in the water tank during winter if the ambient temperature is very low.

Machine Cleaning and Maintenance

• Clean the machine thoroughly after each use.

• Remove dust from the platform and transmission system regularly.

• Lubricate the transmission system (X, Y, Z axes) weekly for optimal performance.

When performing maintenance and inspection of electrical appliances, be sure to cut off the power supply and wait until the monitor has no display and the main circuit power indicator light goes out.

The fasteners of the industrial CNC machine should be inspected for about three months, and the connecting screws on both sides of the gantry, the fastening screws of the screw nuts, and the fastening screws of the motors on both sides should be tightened.

Note: X, Y, and Z three-axis polished rods are maintained with oil, and the screw part is added with high-speed butter, if the working environment temperature is too low in winter, the PRTT ball screw and polished rod (square rail or round rail) part should use gasoline flush and clean, and then add oil, otherwise it will cause excessive resistance in the transmission part of the machine and cause the machine to displace.

Wilson

I think this CNC router will last me many years. I definitely recommend it.

Colwin Bailey

Altantsetseg

Аж үйлдвэрийн CNC машиныг Монголд хурдан хүлээж авсан. Машинд ямар ч гэмтэл гараагүй. Би машин, хүргэлтэд маш их сэтгэл хангалуун байна. Баярлалаа.