After a month of anticipation, I got this CNC machine that I had been looking forward to. I was stunned the moment I opened the package. It was exactly what I expected. My doubts turned into surprises. Since I am a CNC programmer for woodworking, I experienced a short learning curve in software installation and operation. In terms of use, the STM1325CH works great with the automatic tool changing system, and can handle all of my woodworking projects for cabinet making. However, potential buyers should consider the initial investment as well as the operation and maintenance requirements, as this machine is a bit expensive and requires CNC skills from the operator and maintainer. Overall, the STM1325CH stands out for its performance and reliability.

4x8 Linear ATC CNC Wood Router for Woodworking on Sale

4x8 linear ATC CNC wood router machine with a 3.5KW horizontal spindle is designed for making cabinets, wooden doors, furniture, home decorations, wood crafts, musical instruments, windows, and tables. Now the best 4x8 ATC CNC woodworking router table with linear automatic tool changer kit for sale at affordable price.

- Brand - STYLECNC

- Model - STM1325CH

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

An automatic tool changer, or ATC, is the tool package in machining and manufacturing procedures, which allows a CNC (computer numerical control) machine or robot to change tools without human involvement. ATC systems automate the workflow, increasing efficiency and reducing downtime. They assure high precision because of the fast and accurate tool changes made for various operations such as milling, drilling, or cutting. The ATC kits come in useful where there are operations that need a number of tools for one production run, yielding higher productivity and flexibility in the automated CNC system.

ATC CNC Routers: Applications and Industry Benefits

ATC CNC router gives the industry maximum efficiency and versatility. It comes with an automatic tool-changing feature, mainly adopted by woodworking, sign-making, and fabrication. This feature greatly reduces manual intervention, hence increasing productivity. Users will love the precision and ability to easily handle complex designs through advanced software integration and solid construction. With its powerful ATC spindle, large working table, and super-friendly interface, this is the ideal CNC for either a hobby or professional setup.

Benefits of Upgrading CNC Routers with ATC Kits

Upgrading your ordinary CNC router with automatic tool changer kits can change not only the performance and precision but also the efficiency of the machine. Such advanced features include higher spindle speeds, better motion control, and upgraded software in the CNC controller, allowing much more intricate designs to be made with much less processing time. Furthermore, the high-end ATC kits usually have user-friendly interfaces, improved safety features, and compatibility with a wide range of materials, thus rendering them quite versatile in nature for different projects. The upgraded ATC CNC machine can eventually bring better returns on investment and keep your CNC machining operation competitive against a quickly changing landscape.

Here is one of STYLECNC's popular ATC CNC woodworking router machines with a linear automatic tool changer for every need - STM1325CH. Let's start to review this machine in detail.

Features of 4x8 CNC Wood Router with Linear Automatic Tool Changer

• Thick steel welded structure, stable at high temperature, small deformation, good rigidity and high strength.

• Stronger AC servo motor allows the machine to run smoothly, with low noise, high speed, and high precision.

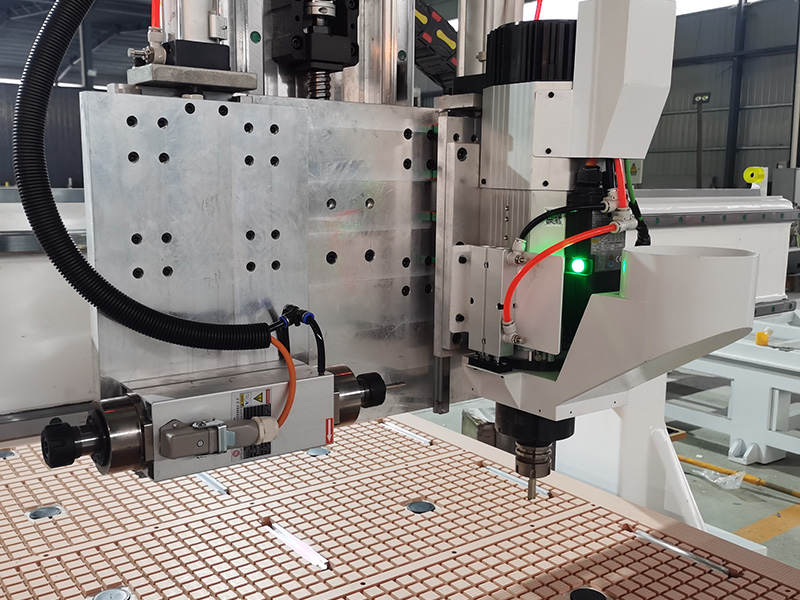

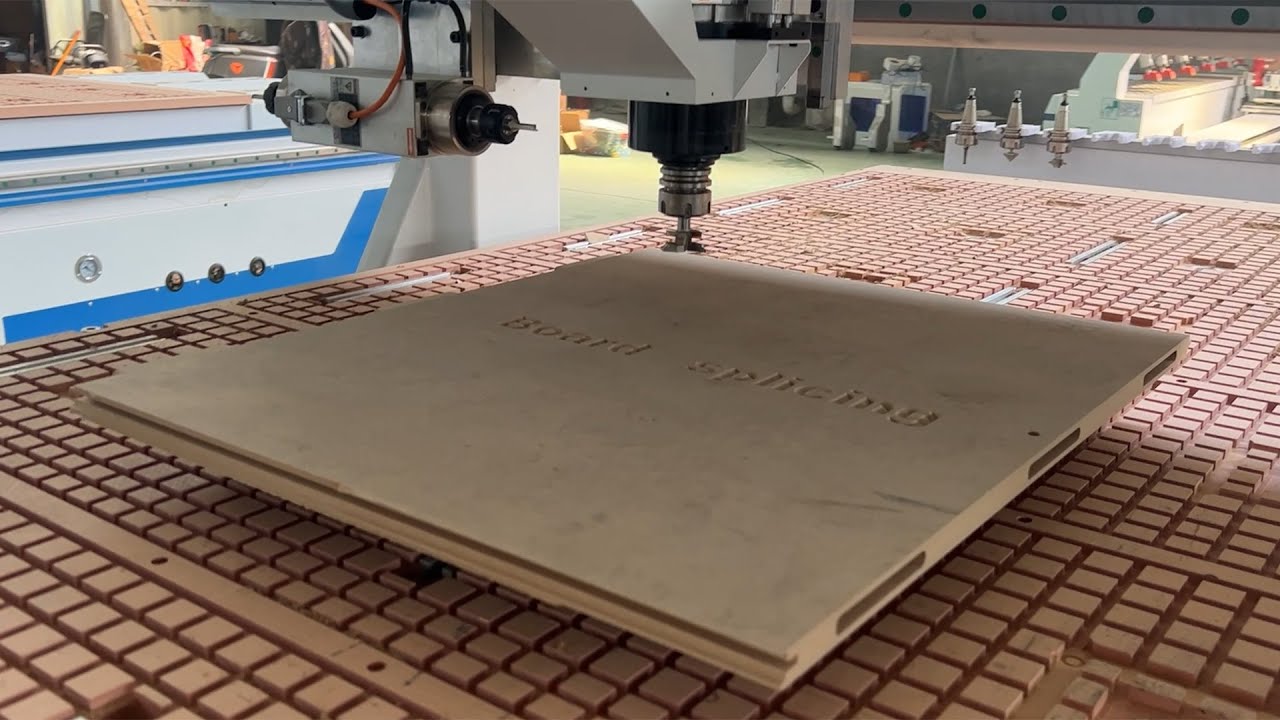

• 9KW air-cooling spindle, high precision, long service life, and smooth movement.

• High-quality 12 tool magazine, high speed tool change within 8 seconds.

• Tool sensor allows the machine to compensate for tool length errors.

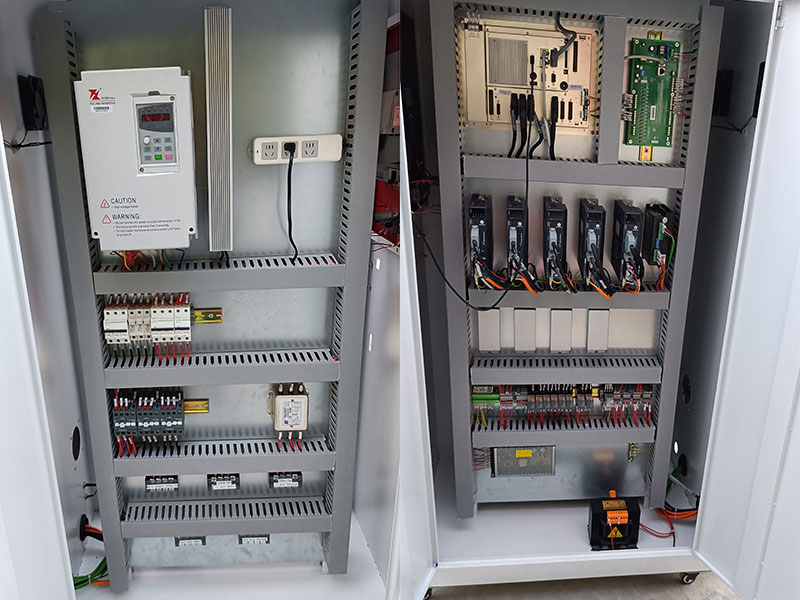

• Top brand Taiwan LNC control system, independent keyboard control, color LCD display, making the machine more versatile.

• Powerful dust collector to ensure site cleanliness during machine operation.

• Automatic lubrication system, one-click easy regular maintenance.

Technical Parameters of 4x8 Linear ATC CNC Wood Router Machine 1325

| Model | STM1325CH |

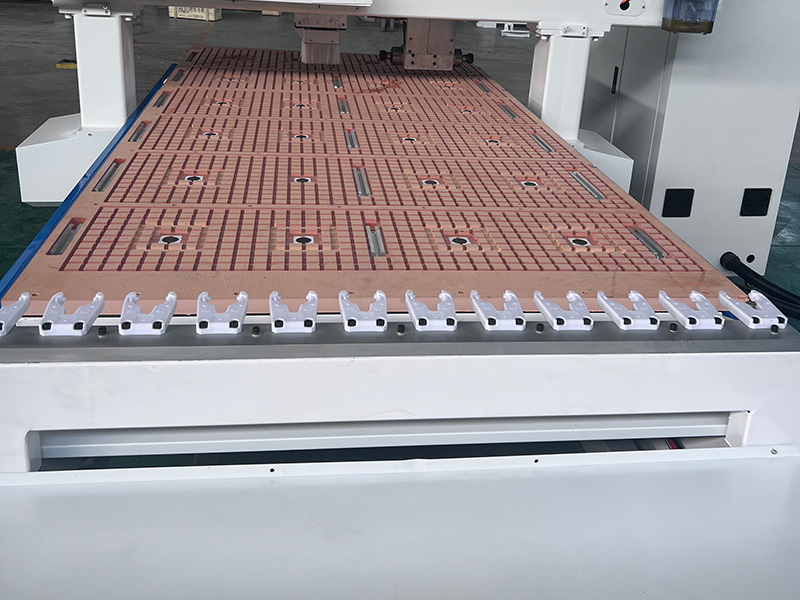

| Table Size | 4' x 8' |

| Working Area | 1300x2500x300mm |

| Resolution | 0.01mm |

| Lathe Structure | Seamless welded steel structure, superior to cast iron structure |

| X/Y Axis Structure | Taiwan Hiwin H30 square guide rail for gear transmission, rack and pinion |

| Z-Axis Structure | Taiwan TBI ball screw, Taiwan Hiwin H30 square guide rails |

| Max. Idling Speed | 50m/min |

| Spindle | 9.0KW air-cooling ATC spindle+3.5KW horizontal spindle |

| Spindle Speed | 0-24000r/min, variable speed |

| Working Voltage | AC380V/3P/50HZ or 220V/2P/3P/60HZ |

| Motor and Driver | 1500W Leadshine servo motor |

| Working Mode | Servo |

| Command | G code (HPGL, U00, mmg, plt) |

| CNC System & Software | Taiwan LNC CNC controller |

| Tool Diameter | φ3.175 - φ12.7 |

| Cooling System | Air cooling |

| Dust Collector | Yes |

| Workholding | Suction or clamp |

| Tool Magazine | Linear type automatic tool changer kit with 12 router bits |

| Net Weight | 2300KG |

Main Parts of 4x8 Woodworking CNC Router Table 1325 with Linear Automatic Tool Changer

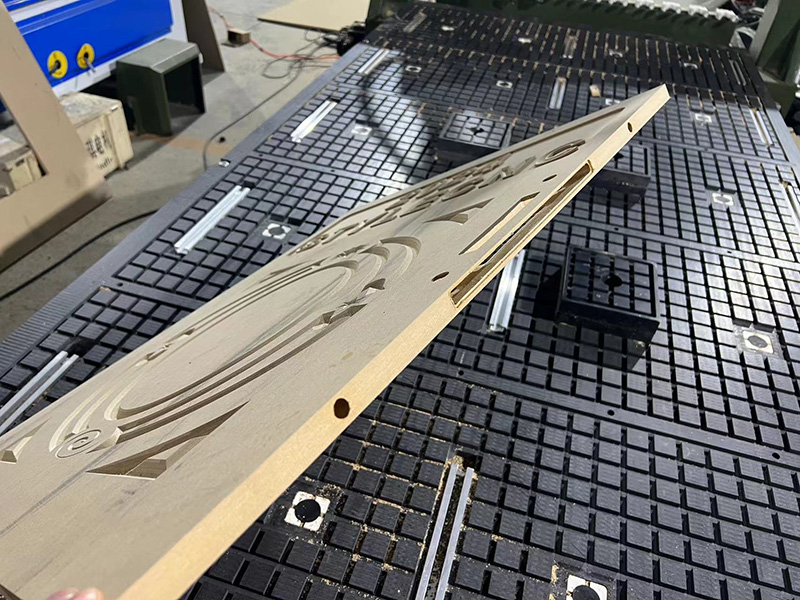

Applications of 4x8 Linear ATC Wood CNC Router 1325 with Automatic Tool Changer

Linear ATC CNC Wood Working Machine is normally used in furniture, furniture-making industry, furniture decoration industry, wood craft industry, wood decoration industry, automotive tooling industry, solid wood furniture, classical furniture, decoration material, door cabinets, and wooden kitchen furniture. The Linear ATC wood CNC machine is specially designed for milling and cutting wood, acrylic, plastic, PVC, stone, MDF, bamboo, and some soft metal materials like aluminum, brass, and copper.

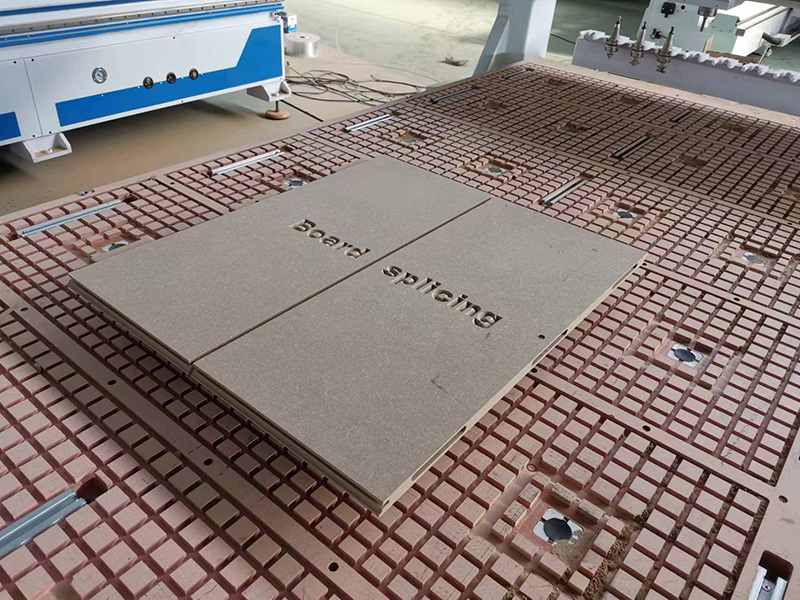

4x8 Linear ATC CNC Router for Woodworking Projects

How to Maintain Your 4×8 CNC Router for Peak Performance?

Carrying out routine maintenance on a 4×8 router will extend its life and keep it running smoothly for longer. A well-maintained router gives consistent results without failure, saving one a lot of time and money. Here's how to go about maintaining your machine in the best condition.

• Clean the Work Area Daily: Operations can build up dust and debris in a very short period. Clean up the worktable and all moving parts daily to prevent wear and tear. Use a soft brush or vacuum for effective cleaning.

• Lubricate Moving Parts Regularly: Keep rails, screws, and bearings nice and lubricated. Lower friction reduces rust, keeping the working process smooth and prolonging the machine's life span.

• Electrical Component: Inspect for loose wires, damaged cables, or components that are burnt out. Regular inspections assist in avoiding breakdowns unexpectedly and enhance the level of safety.

• Cooling System: Make sure the water/air cooling system is working correctly to avoid overheating that may potentially damage the spindle among other parts.

• Tool Alignment: Poor adjustment of the tools results in cut inaccuracy and may eventually cause damage. The machine should be calibrated periodically to retain accuracy and efficiency.

• Software and Firmware Update: Keep updating software installed in your machine. Updates usually contain improvements in performance and bug fixes.

• Perform Scheduled Maintenance: Follow the maintenance schedule provided by the manufacturer. Routine servicing by professionals can identify hidden issues and prevent major repairs.

Why the 1325 Linear ATC CNC Wood Router is a Great Investment for Woodworkers

The 1325 Linear ATC CNC Wood Router stands out as an excellent choice for woodworkers, combining efficiency, precision, and versatility. Here's why it's worth the investment.

Time-Saving Automatic Tool Change

The linear ATC system allows the machine to switch tools automatically during operations. This eliminates manual tool changes, reducing downtime and improving productivity. It’s especially beneficial for projects requiring multiple tools.

Large Work Area for Versatile Projects

The 1325 model features a spacious worktable, accommodating large pieces of wood. Whether it’s furniture making, cabinetry, or intricate designs, the size is ideal for diverse woodworking tasks.

Exceptional Cutting Precision

Equipped with advanced spindles and a robust frame, the router delivers high precision. This ensures clean, accurate cuts, enhancing the quality of your finished products.

Durable and Reliable Design

Built with high-quality materials, the 1325 router is designed for heavy-duty use. Its sturdy construction ensures stability and reduces vibrations, even during intensive operations.

User-Friendly Operation

The machine features an intuitive control system, making it easy for beginners and professionals alike. Its compatibility with popular design software adds to its convenience.

We also have other ATC CNC routers with automatic tool changer kits for option.

Disc ATC CNC Router Table with 4th Rotary Axis

ATC CNC Wood Router Kit with Dual Disc Tools Magazine

Automatic ATC CNC Woodworking Router Machine with Tool Changer

Reginald Kidder

Gökhan Bağrıaçık

CNC ahşap oyma makinesi ile ev kapısı yapmaya çalıştım, çok iyi çalıştı, harika bir makine. Keşke biraz daha ucuz olsaymış ama yine de değdiğini söyleyebilirim.

David Rusnac

Easy to assemble and got going to make cabinet doors. Everything was perfect. Sturdy enough for hard wood and aluminum. In addition, the 4x8 working table is perfect for full sheet cuts.

Naoufel Mlayah

نوعية جيدة من أداة آلة النجارة الأوتوماتيكية. مصنع رائع. دعم ممتاز. على جميع الأسئلة تلقى إجابة شاملة. شكرًا لك.