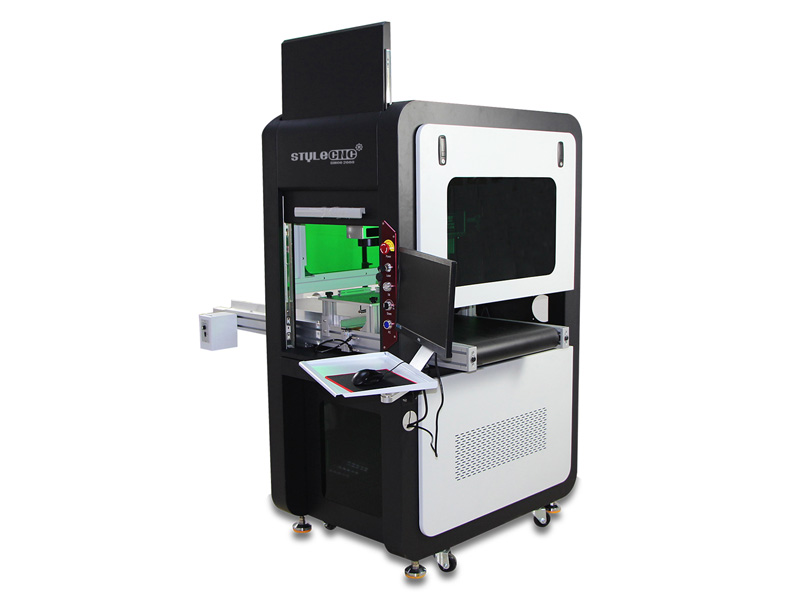

Laser Marking Machine with CCD Visual Positioning System

Looking for a budget-friendly laser marking system for mass production with diversified and complex engravings? Review the best laser marking machine of 2025 with CCD visual positioning system. You'll get an affordable solution with best budget for precise etching and continuous marking.

- Brand - STYLECNC

- Model - STJ-50F-C

- Maker - Jinan Style Machinery Co., Ltd.

- Category - Fiber Laser Marking Machine

- 320 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

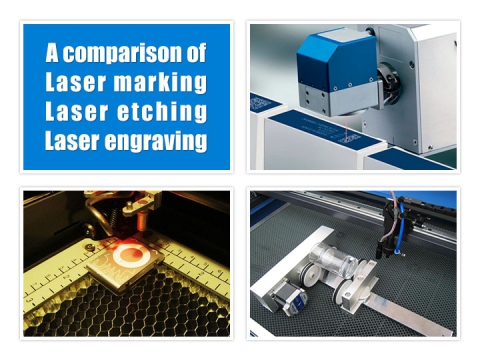

What is a Laser Marking Machine?

A laser marking machine is an engraving system that generates a high-energy continuous laser beam by a laser generator. The focused laser acts on the printing material to instantly melt or even vaporize the surface material. By controlling the path of the laser on the surface of the material to form the required graphic marks.

What is a CCD Visual Positioning System?

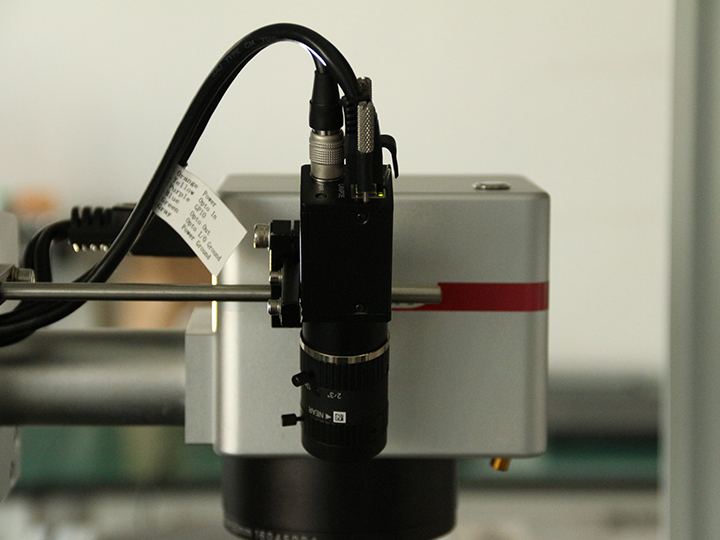

CCD visual positioning system is a visual motion control system developed for the needs of higher precision camera positioning identification, marking, engraving, or cutting. It has the characteristics of high precision and high stability. It is mainly used in laser marking, engraving, and cutting machines. At the same time, the system can also be used as an ordinary laser motion control system. CCD visual positioning system is a high-tech product used for industrial detection and identification. The core issue of production is the selection of an industrial computer system, which can collect high-definition images of processed products and directly transmit them to the GPIO interface of the machine.

With the rapid development of technology in digital image processing and computer vision, an increasing number of researchers have chosen cameras to be the perception sensors of their fully autonomous mobile robots. The main reason is probably that the original ultrasonic or infrared sensors contain limited information and are poorly robust, and the visual system can help make up for these weaknesses. The real world is three-dimensional, while the image projected on the camera lens (CCD/CMOS) is two-dimensional. The ultimate aim of visual processing is the extraction of relevant three-dimensional world information from the perceived two-dimensional image.

How Does the CCD Visual Positioning System Work?

Due to the rapid development of digital image processing and computer vision technology, more and more researchers have adopted cameras as the perception sensors of fully autonomous mobile robots.

The filter-based positioning algorithms of the CCD visual positioning system mainly include KF, SEIF, PF, EKF, and UKF. The method of combining monocular vision and an odometer can also be used. Using the odometer reading as auxiliary information, the coordinate position of the feature point in the current robot coordinate system is calculated by triangulation. The three-dimensional coordinate calculation here needs to be carried out based on a delay of a one-time step.

2025 Best Laser Marking Machine with CCD Visual Positioner Advantages

• The products' position and angle can be freely placed on the conveyor belt, and the CCD vision system automatically captures without fixture positioning, and automatically marking.

• The visual positioning system enlarges the marking area and solves the accuracy problem of the small parts.

• Adopts a coaxial CCD camera, the marking position is accurate, without missing or re-marking.

• It can be equipped with an assembly line or other automatic loading and unloading mechanism to realize automatic marking.

• Especially suitable for product processing such as heavy workload, difficult feeding positioning, and diversified and complex workpieces.

Applications of 2025 Best Laser Marking Machine with CCD Visual Positioner

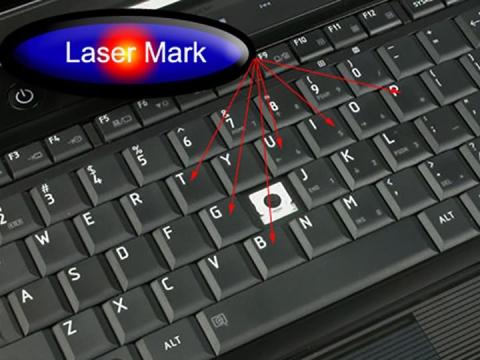

This fiber laser marking machine is especially suitable for marking ultra-high-precision and valuable parts which is not easy to be positioned by hand, it can identify the shape and marking area of the object in the software. Lt is widely suitable for all kinds of metals, aluminum, aluminum alloy, deep carved metal, hard plastic, and many sensitive materials and PVC. Especially good for marking IC chips, circuit boards, resistors, small capacitors, metal buttons, pens, etc.

Best applied for assembly lines that need productivity and high precision industries, such as electronic parts, communication, medical equipment, precision mechanics, the gold industry, metal buttons, stationery, and many other industries.

Technical Parameters of CCD Visual Positioning Laser Marking System

| Model | STJ-50F |

| Laser Power | 50W |

| Laser Wavelength | 1064nm |

| Fiber Cable Length | 3m |

| Pulse Width | 200ns |

| Repetition Frequency Range | 1-600kHz |

| M2 | <1.8 |

| Max Single Pulse Energy | 1.25mJ |

| Laser Power Stability | <5% |

| Laser Beam Diameter | 7±1mm |

| Power Range | 10% - 100% |

| Marking Range | 110*110mm/175*175mm/200*200mm/300*300mm |

| Minimum Line Width | 0.01mm |

| Minimum Character | 0.1mm |

| Marking Speed | ≤7000mm/s |

| Marking Depth | Depend on materials |

| Repeatability Accuracy | ±0.001mm |

| Marking Format | Graphics, text, bar codes, QRcode, date, batch number, serial number. |

| Graphic Format Supported | ai, plt, dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

| Working Voltage | 220V±10%/50Hz or 110V±10%/60Hz or Customized |

| Unit Power | <0.5kw |

| Working Environment | Clean and dust free or dust less |

| Working Condition Humidity | 5%-75%, 0-40 degrees, free of condensed water |

| Laser Lifetime | >100000 hours |

| Net weight | 230 kgs |

| Packing Size | 1230*950*1800mm |

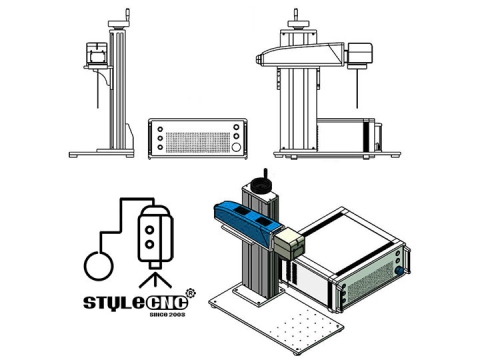

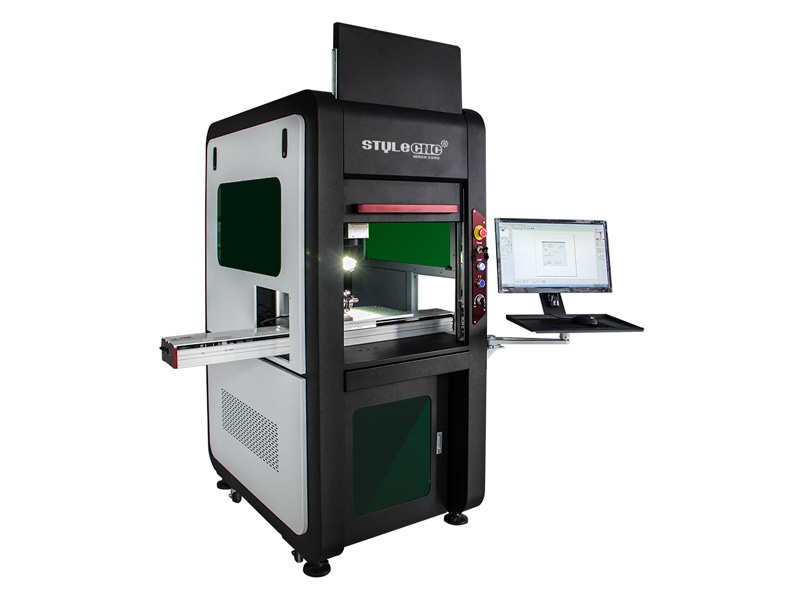

Details of CCD Visual Positioning Laser Marking System

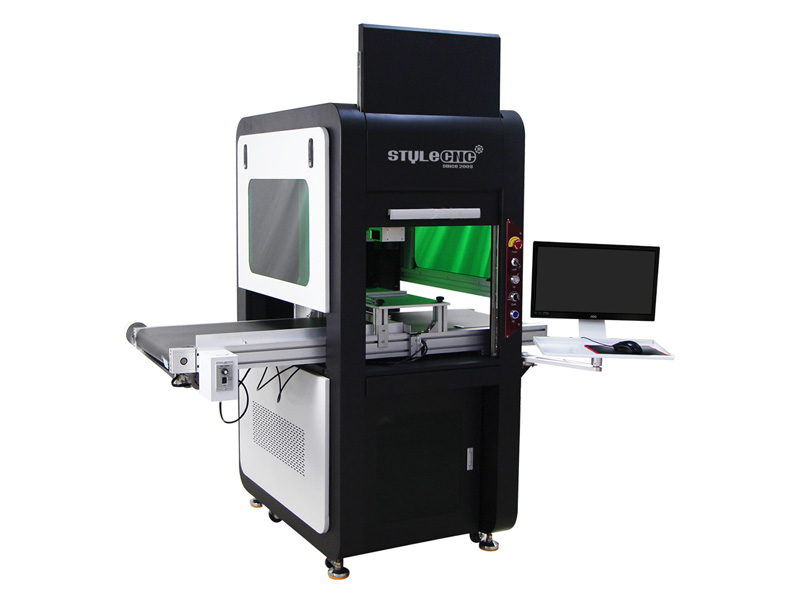

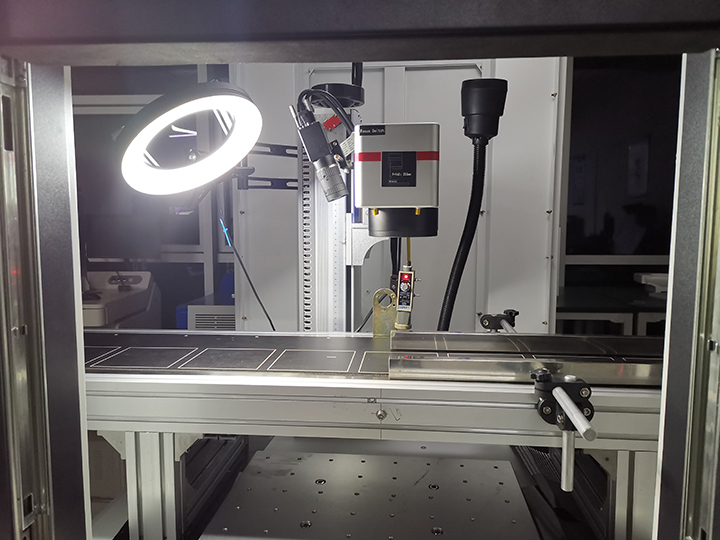

Enlosed fiber laser marking system with X axis table.

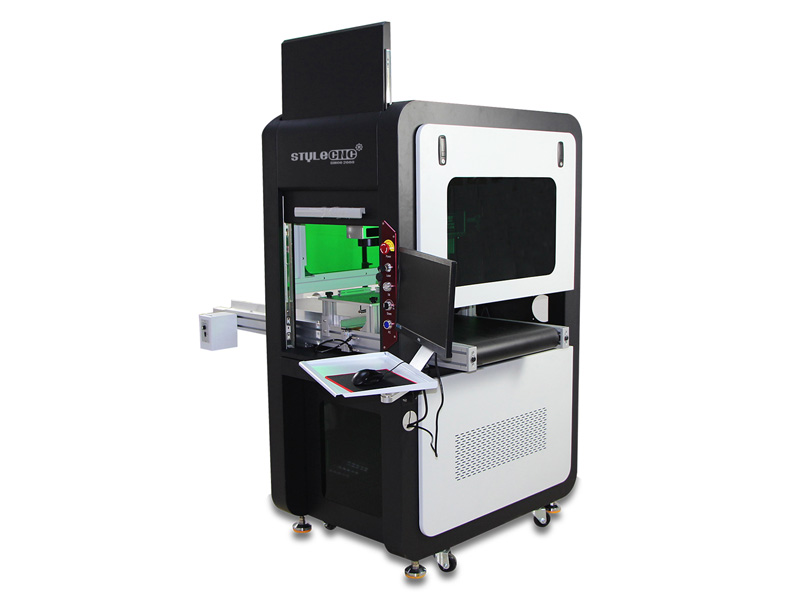

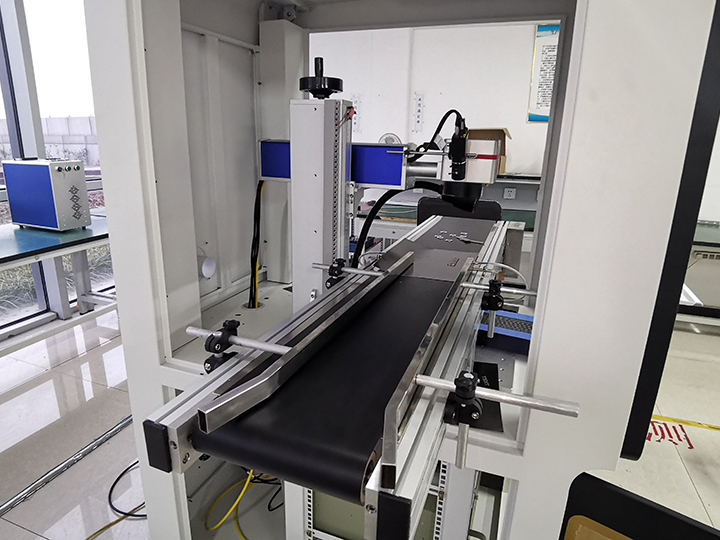

Enlosed fiber laser marking system without conveyor belt.

CCD Visual Positioning Laser Marking Machine Projects

How to Choose the Right Laser Marking Machine with a CCD System

Choosing the right laser marking machine equipped with a CCD visual positioning system will greatly enhance the precision and efficiency of your marking tasks. Here are key factors to consider when choosing the perfect machine for your needs.

1. Material Compatibility

Assess the material you are working with. Laser marking machines with a CCD system can work with metals, plastics, ceramics, and many other materials. Ensure the machine you choose is compatible with your specific materials, as some systems may work better with certain surfaces than others.

2. Marking Accuracy and Precision

The biggest benefit a CCD system can provide is accuracy enhancement. It provides for automatic alignment and the precise positioning that is so critical in many applications where small margins of error may be tolerated, as in electronics or medical. If your projects require fine detail, ensure the machine offers the resolution and precision you need.

3. Speed and Efficiency

If you are going to run high-volume production, then speed becomes very important. The inclusion of a CCD positioning system in a laser marking machine, will save considerable time on the positioning of the laser and, consequently, on every marking. Look for a machine that balances high-speed operation with the precision required for your applications.

4. Ease of Use

A machine with an intuitive interface can make a world of difference, especially when you are new to this technology. The visual positioning facility provided by the CCD system should not be cumbersome to use - it should allow rapid setup and adjustments. The software and controls should be simple yet powerful enough for your applications.

5. Cost and Long-Term Investment

While CCD systems give better performance, they are generally higher in price. The long-term benefits it will provide, such as reduced errors and downtime, improved efficiency, and better-quality marks, make it well worth the investment. Consider your budget and weigh the benefits of investing in a machine that will provide lasting value.

The balance of material compatibility, precision, speed, ease of use, and cost determines the choice in selecting the right laser marking machine with a CCD system. You will be able to determine the solution that will fulfill your needs in marking precisely, enhancing your overall production process by carefully considering these elements.

Brad Sparks

William McGough

Hermann

The STJ-50F makes a super solid impression and has performed the tasks so far with bravura. All quiet, good quality, recommend the laser marking machine to everyone.