2025 Best Entry Level Small Laser Engraver for Beginners

2025 best small laser engraver is an entry level laser engraving machine with compact structure for beginners to engrave, etch, and cut crafts, arts, gifts of wood, MDF, acrylic, crystal, plastic, glass, paper, leather, fabric or stone in small business, small shop, home business, home shop. Now the cheapest mini laser etching machine for sale at low price.

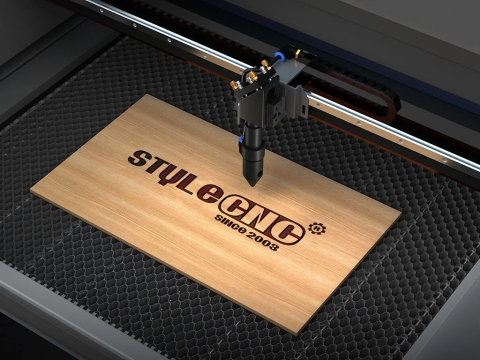

- Brand - STYLECNC

- Model - STJ9060

- Maker - Jinan Style Machinery Co., Ltd.

- Category - Laser Engraving Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Overview

Mini laser engraver is a type of small laser etching machine with compact structure for beginners in small business, small shop, home business, home shop, hobbyists, school education. The entry level small laser engraver can engrave and cut letters, signs, logos, numbers and patterns as crafts, arts and gifts on fabric, wood, MDF, stone, crystal, plastic, acrylic, glass, paper or leather. Mini laser engraver is also known as mini laser engraving machine, small laser engraver, small laser engraving machine, compact laser engraver, compact laser engraving machine, entry level laser engraver, entry level laser engraving machine.

Small laser engraving machine is an advanced equipment that uses laser to engrave materials that need to be engraved. The compact laser engraving machine is different from the mechanical engraving machine and other traditional manual engraving methods. The mechanical engraving machine uses mechanical means, while the laser engraving machine uses the thermal energy of the laser to engrave materials. The laser generator in the entry level laser engraving machine is its core Where. Generally speaking, the use range of laser engraving machine is more extensive, and the engraving accuracy is higher, and the engraving speed is also faster. And compared to the traditional manual engraving method, laser engraving can also achieve a very delicate engraving effect, no less than the level of hand-engraving craftsmanship. It is precisely because the laser engraving machine has so many advantages, so now the small laser engraving machine has gradually replaced the traditional engraving equipment and methods.

Mini laser engraving machine includes a CO2 laser tube and a gas nozzle on its output light path. One end of the gas nozzle is a window, and the other end is a nozzle coaxial with the laser light path. The side of the gas nozzle is connected with a gas pipe, especially the gas pipe and the air. Or an oxygen source is connected, the pressure of the air or oxygen source is 0.1 to 0.3 MPa, the inner wall of the nozzle is cylindrical, the diameter is 1.2 to 3 mm, and the length is 1 to 8 mm; The oxygen in the oxygen source occupies 60% of its total volume, and a reflector is arranged on the optical path between the laser and the gas nozzle. It can improve the efficiency of engraving, make the surface of the engraved place smooth and round, quickly reduce the temperature of the engraved non-metallic material, and reduce the deformation and internal stress of the engraved object. The small laser engraving machine widely used in the field of fine engraving of various non-metallic materials.

2025 Best Small Laser Engraver Features & Advantages

1. The mini compact laser engraver can work for organics, non-metal, it is able to mark pre-treated metals.

2. Fine engraving, the small compact laser engraver adopts top brand USA professional optical lens, the laser beam is more stable.

3. Precise red light positioning system.

4. Facilitate discharge and reclaimer system, with lifting up and down to adjust the front-end to be completely open.

5. The small laser engraving system supports AUTOCAD, CORELDRAW, PHOTOSHOP and other design softwares, the human-machine interface is friendly.

6. The working area of the mini laser engraver: 900*600mm, this can be customized according to your requirements.

7. DSP control system: The laser engraving machine has USB interface in the control panel, which will support the offline work, you have no need to connect the computer, this is very convenient.

8. Knife worktable/Honeycomb worktable for your option: Knife worktable is better for hard materials such as wood, acrylic. Honeycomb worktable use for soft materials such as leather, fabric, etc.

9. High resolution laser head: High quality and long lifetime.

10. Water pump: It is used for cooling laser tube to protect it has long life.

11. Air pump/Compressor: It is used for cooling the laser head to avoid the materials to be burned.

12. Exhaust fan: Blow away the smoke.

13. Tool box: Includes the CD, User manual and some wrenches for your work.

Entry Level Small Laser Engraver Technicial Parameters

| Model Type | STJ9060 |

| Laser type | Sealed CO2 laser tube |

| Laser power | 60W - 100W |

| Engraving area | 900*600mm |

| Resetting position accuracy | +/-0.05mm |

| Working voltage | AC110-220V +/-10%.50-60HZ |

| Minimum shaping character | English 1*1mm |

| Graphic format supported | BMP, PLT, DST, DXF and AI |

| Driving system | Stepper |

| Cooling mode | Water-cooling and protection system |

| Auxiliary equipment | Exhaust-fan, air-exhaust pipe |

| Controlling software | RD control system |

| Compatible software | Coreldraw, AutoCAD, Photoshop |

2025 Best Small Laser Engraving Machine Details

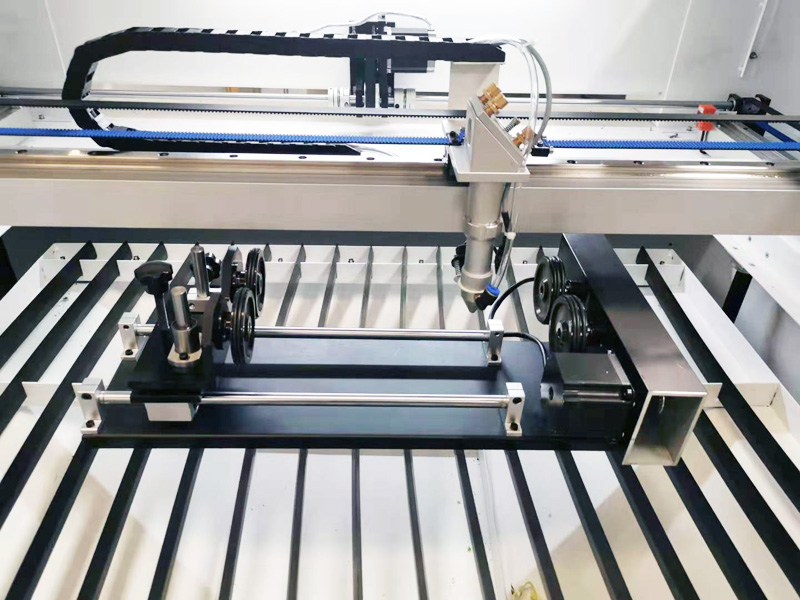

Entry Level Small Laser Engraver Machine Accessories

RUIDAworksV8 SYSTEM

The small laser engraving sytem has powerful processing functions, visual operation and easy to learn , can meet almost all customer processing requirements.

INDUSTRIAL LASER HEAD

The laser head of the compact laser engraving machine for wood crafts enclosed jet design protects the lens from dust and keeps the lens highly translucent.

HIGH-SPEED MOTORS

With stepper motors, the engraving speed can reach 800mm/s and the cutting speed can reach 500mm/s.

HIGH-QUALITY GUIDE LINEAR RAIL

The entry lever laser etching machine adopts stainless steel guide rail, moving slider bearing design, smaller friction coefficient, higher precision, faster operation with motor.

LASER LENSES

The mini laser engraving machine uses High-Quality laser lenses to ensure more precise laser beam focusing, finer laser beam and longer life.

LASER TUBES

The small laser etching machine uses laser tubes of famous brand like RECI, WEIJU, EFR to ensure the stability of the light source and service life.

2025 Best Small Laser Engraver Applications

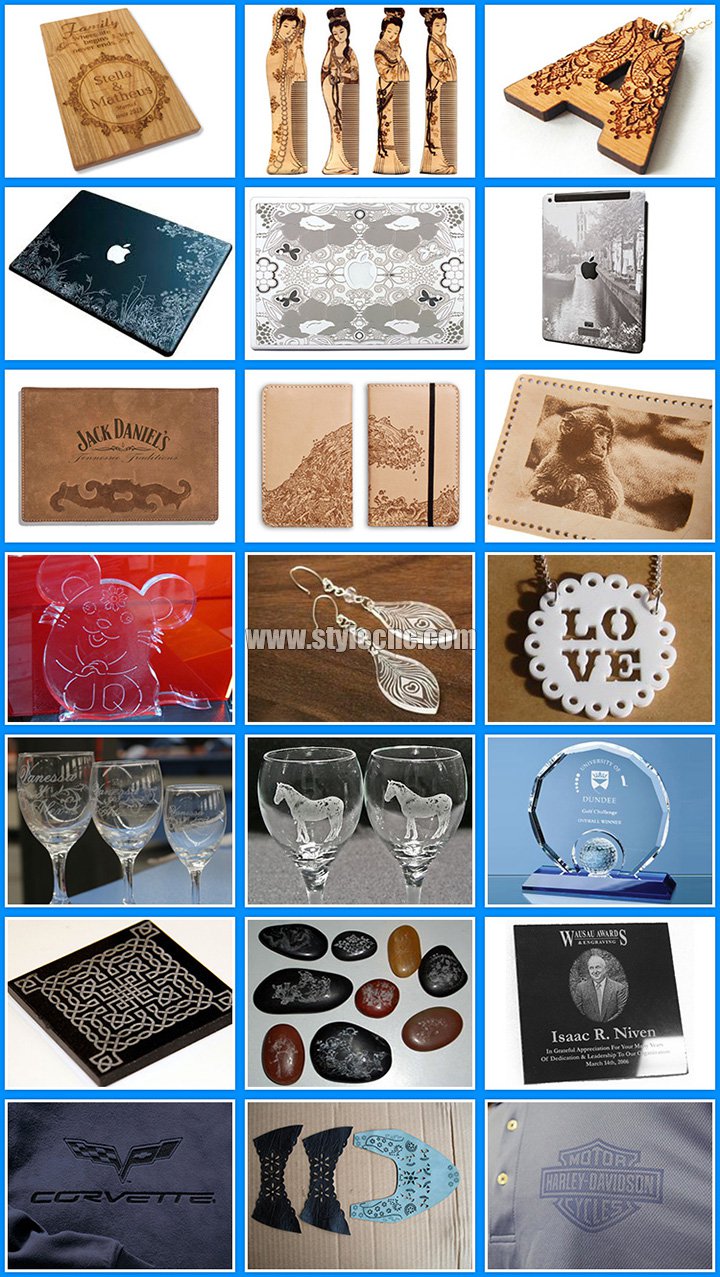

The small compact laser engraving system can engrave, etch and cut various non-metal materials.

| Materials | Engrave | Cut |

| Wood/ MDF/ Cork | Yes | Yes |

| Acrylic/ Crystal/Plastic | Yes | Yes |

| Glass | Yes | No |

| Acetate/ Delrin | Yes | Yes |

| Rubber/Stamp/ Silicon | Yes | Yes |

| Paper/Card/ Pressboard | Yes | Yes |

| Fiberglass / Mylar | Yes | Yes |

| Leather/ Cloth | Yes | Yes |

| Fabric/Cotton | Yes | Yes |

| Silk/Textile | Yes | Yes |

| Marble/Granite/Stone | Yes | No |

| Ceramic/ Tile | Yes | No |

What Is A Mini Compact Laser Engraver Used For?

Applicable Industries:

Arts and crafts, gifts, toys, advertisement, car, mechanism, trademarks, electron, embroidery, custom signs, clothing and other industries.

Available Materials:

Plastic engraving and cutting, Acrylic engraving and cutting, rubber engraving, PVC engraving and cutting, seal engraving, plexiglas engraving, organic glass engraving, marble engraving, paper engraving and cutting, gum engraving, granite engraving, EVA foam cutting, plywood engraving and cutting, MDF engraving and cutting, wood engraving and cutting, bamboo engraving and cutting, textile engraving and cutting, leather engraving and cutting, fabric engraving and cutting, shoes engraving and cutting, jeans engraving and cutting, carpet engraving and cutting, denim engraving and cutting, woolen cutting, toy cutting.

2025 Top Rated Small Laser Engraver Projects

How Does A Mini Laser Engraver Work?

Dot Matrix Engraving

Dot matrix engraving resembles high-definition dot matrix printing. The laser head swings left and right to engrave a line composed of a series of dots each time, and then the laser head moves up and down to engrave multiple lines at the same time, and finally constitutes a full-page image or text. The scanned graphics, text and vectorized graphics can all be engraved by dot matrix.

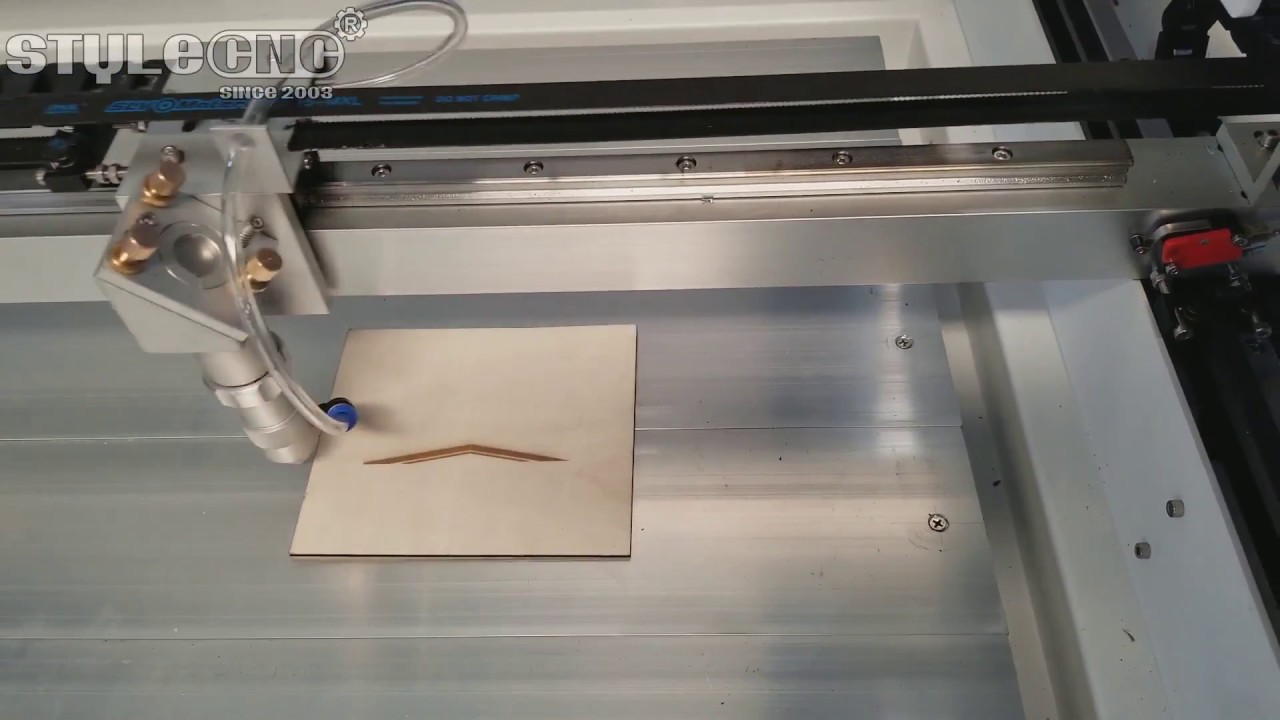

Vector Cut

Unlike dot matrix engraving, vector cutting is performed on the outer contour of the graphic. We usually use this mode for penetrating cutting on wood, acrylic, paper and other materials, as well as marking on the surface of a variety of materials.

Engraving Speed

Engraving speed refers to the moving speed of the laser head, usually expressed in IPS (inch/second), high speed brings high production efficiency. Speed is also used to control the depth of cutting. For a specific laser intensity, the slower the speed, the greater the depth of cutting or engraving. You can use the panel of the engraving machine to adjust the speed, or use the computer's print driver to adjust. In the range of 1% to 100%, the adjustment range is 1%. The advanced motion control system of the Hamm machine allows you to still get ultra-fine engraving quality when engraving at high speed.

Engraving Intensity

Engraving intensity refers to the intensity of the laser that hits the surface of the material. For a specific engraving speed, the greater the intensity, the greater the depth of cutting or engraving. You can use the panel of the engraving machine to adjust the intensity, or you can use the computer's print driver to adjust. In the range of 1% to 100%, the adjustment range is 1%. The greater the intensity, the greater the speed. The depth of the cut is also deeper.

Spot Size

The size of the laser beam spot can be adjusted with lenses with different focal lengths. A lens with a small spot is used for high-resolution engraving. A lens with a large spot is used for lower resolution engraving, but it is the best choice for vector cutting. The standard configuration of the new device is a 2.0-inch lens. The spot size is in the middle, which is suitable for various occasions.

Engraving Materials

Wood, plywood, MDF, plexiglass, glass, stone, crystal, corian, paper, alumina, leather, resin, plastic, acrylic.

Small Laser Engraving Machine Parts

Feeding Mechanism

The laser beam can move along the Y direction, and the laser head moves along the X axis on the beam. The X/Y axis is driven by a stepper motor, and the side length of the X axis stepper motor is 57mm.

CO2 Laser Tube and Optical Path

Laser tube, three mirrors and a convex lens.

The laser tube is fixed on the back of the machine and emits invisible infrared laser. The laser reaches the surface of the workpiece through three mirrors and a convex lens. This requires that the beam between the first mirror and the second mirror be parallel to the machine tool Y axis; the beam between the second mirror and the laser head is parallel to the machine tool X axis. The vibration of the machine, especially the severe impact, will gradually deviate the reflector from the original position, so each reflector needs to be adjusted regularly.

When the lens and reflector are contaminated, they will absorb more energy in the laser, and the temperature will rise, causing explosions. Therefore, they should be cleaned with organic solvents on a regular basis.

Remove the laser tube before moving the machine, install it after moving, and readjust the light path.

A 10mW laser can damage the retina. The laser power of a laser engraving machine is tens of watts and the beam is invisible, so be careful.

Laser Head

The laser head contains a mirror and a convex lens that can be adjusted up and down. Generally, the convex lens needs to be adjusted so that its focus falls on the upper surface of the workpiece. The convex lens that can be installed in this laser head is a model with a diameter of 20mm and a focal length of 50.8mm. When installing, the convex surface faces upwards, that is, the direction in which the laser is incident.

CNC Controller

The CNC controller is located near the air switch on the left side of the machine tool (inside), and is responsible for communicating with the PC, sending pulses to the stepper motor driver and laser tube controller, displaying information through the panel and accepting key input, etc.

Water Chiller

CW-3000 Industrial Water Chiller

The chiller provides power for the laser tube cooling water circulation, and uses a fan to reduce the temperature of the cooling water. If the water circulation is blocked, the machine will sound an alarm and prevent the laser tube from igniting.

The chiller model is CW-3000, and the water tank capacity is 9 liters. Fill the water tank with distilled water and change the water once a year.

Air Pump

The air pump presses air into the laser head and generates a high-speed jet at the nozzle of the laser head. The air pump has the following functions:

Cooling convex lens;

Prevent smoke and dust from adhering to the convex lens;

The jet prevents the workpiece from catching fire;

The jet blows away the material melted by the laser;

Normally, the air pump should be kept on during processing.

Exhaust Fan

The exhaust fan draws air from the mini engraving machine and exhausts it from the exhaust pipe to the outdoors, achieving the purpose of reducing indoor odors. Under normal circumstances, the cover door should be closed and the fan should be kept open during processing.

Power Distribution Box

The power distribution box is located on the back of the small laser machine, which can be seen by removing the cover. There are AC to DC switching power supplies, stepper motor drivers, relays, terminals, etc.

Laser Power Supply

The laser power supply is located on the right side of the laser machine, which can be seen by removing the cover. The laser power supply provides thousands of volts of high voltage for the laser tube.

Small Laser Engraver Services & Support

1. Guarantee for 2 years.

2. Maintenance for whole life.

3. We will provide the consumable parts at an agency price.

4. 24/7 online service, free technical support.

5. The laser machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, please kindly tell us.

6. We have manual instruction and guiding videos for software installation, operation and laser machine's using and maintenance.

Montague

Burak

Küçük lazer oyma makinesinden çok memnunum. Kurulumu ve kullanımı çok kolay ve ilk aldığım gün ahşap bir içecek altlığı oydum. Alışma süreci hızlıydı. Bir çift koruyucu gözlükle birlikte gelir, ancak birkaç tane daha satın almanızı öneririm. Ailem, kontrol etmek için etrafta toplanmak istedi.