Affordable Laser Engraver for Leather, Fabric, Paper, Jeans

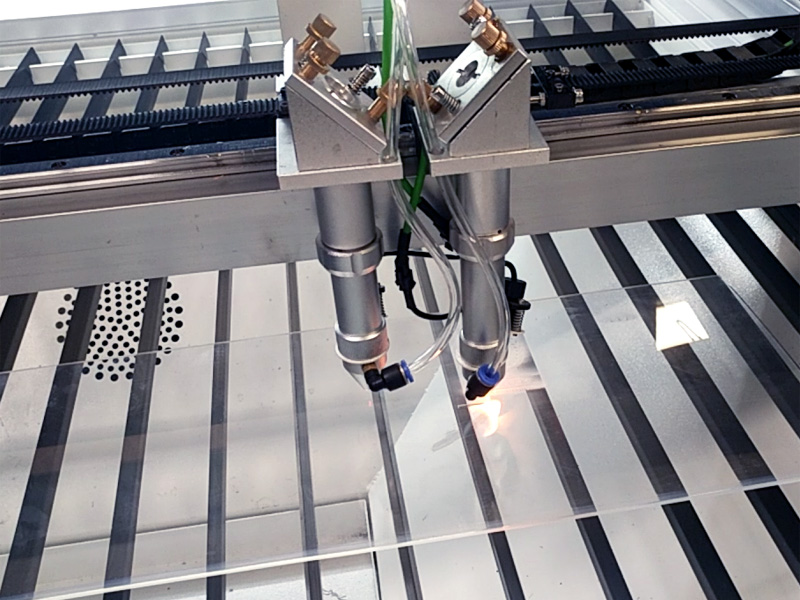

Affordable CO2 laser engraver is designed for cutting, etching & engraving genuine leather, synthetic leather, leatherette, fabric, textile, paper, cardboard, jeans, fibers and more flexible materials, which is also known as leather engraving machine, fabric engraver, paper printer, jeans marker. Now the cheap laser engraving machine for sale at affordable price.

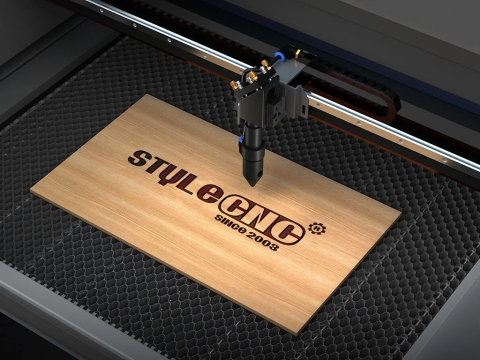

- Brand - STYLECNC

- Model - STJ1390-2

- Maker - Jinan Style Machinery Co., Ltd.

- Category - Laser Engraving Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What You Should Know About Laser Engraving Machine?

Laser engraving machine refers to the operation method of connecting laser equipment to laser engraving software, and inputting artwork into automatic engraving. At present, laser engraving machine is the most mature and widely used technology in the field of laser processing. Using this technique, any complex graphics can be engraved. It can carry out hollow engraving and non-penetrating blind groove engraving, thereby engraving out various magical patterns with different shades, different textures, layering and transitional color effects. With these advantages, laser engraving caters to the new trend of international clothing processing.

Although laser engraving is also a thermal processing method, it is very suitable for cutting textile fiber fabrics due to the high focus of the laser, the slender spot, and the small thermal diffusion zone. The specific performance is in the wide range of processing fabrics, smooth cuts without flash, automatic closing, no deformation, graphics can be designed and output by computer at will, no knife die, etc. This makes laser processing a recognized alternative in the industry.

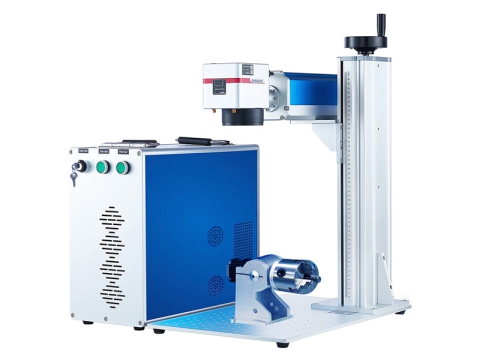

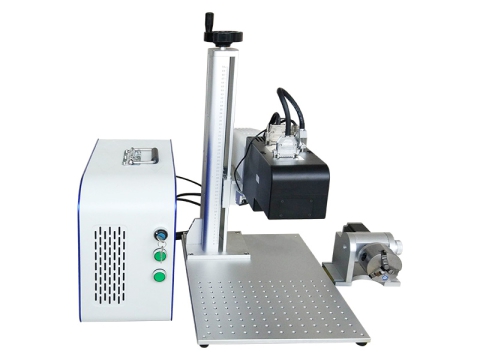

Laser engraving machine, as the name suggests, is an advanced equipment that uses laser to engrave nonmetal materials that need to be engraved. The nonmetal laser engraving machine is different from the mechanical engraving machine and other traditional manual engraving methods. The mechanical engraving machine uses mechanical means, such as diamond and other extremely hard materials to engrave other things, while the laser engraving machine uses the heat energy of the laser to carry out the material.

Generally speaking, the use range of nonmetal laser engraver is more extensive, and the engraving accuracy is higher, and the engraving speed is faster. And compared to the traditional manual engraving method, laser engraving can also achieve a very delicate engraving effect, no less than the level of hand-engraving craftsmanship. It is precisely because the laser engraver has so many advantages, so now the application of laser etching machine has gradually replaced the traditional engraving equipment and methods.

What You Should Know About Laser Leather Engraving Machine?

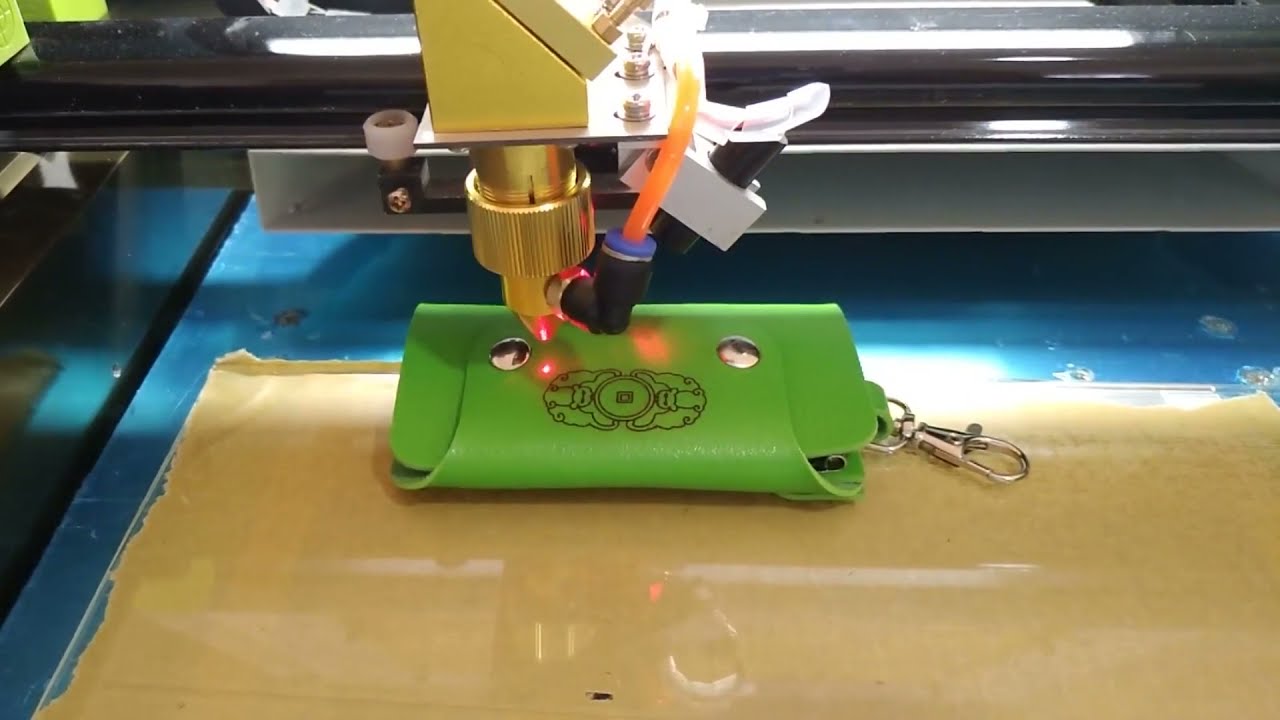

A leather laser engraving machine can be used to etch & engrave text, logo, sign, letter, number, pattern, picture or cut profiles & shapes with leathers, including suede leather, natural leather, alcantara leather, nubuck leather, synthetic leather, and napped leather. A leather laser engraver is also known as leather laser etching machine, laser leather engraving machine.

Laser technology is currently widely used in the leather industry. The advantage of laser is that it can quickly engrave and hollow out various patterns on various leather projects, and it is flexible in operation, and it will not cause any deformation on the leather surface to reflect the color and texture of the leather itself. It also has many advantages such as high engraving precision, hollow out without burrs, and arbitrary shape selection. Laser leather engraving refers to the operation method of connecting laser equipment to laser engraving software and inputting the artwork into automatic engraving. At present, laser leather engraving is the most mature and widely used technology in the field of laser processing. Using this technique, any complex graphics can be engraved. It can carry out hollow engraving and non-penetrating blind groove engraving, thereby etching out various magical patterns with different shades, different textures, layering and transitional color effects. With these advantages, leather laser engraving caters to the new trend of international clothing processing.

Laser leather engraving machines are currently widely used in shoe and leather industries. The advantage of laser leather engraver machine is that it can quickly engrave and hollow out various patterns on various leather fabrics, and it is flexible in operation, and it will not cause any deformation on the leather surface to reflect the color and texture of the leather itself. It also has many advantages such as high engraving accuracy, hollowed out without burrs, and arbitrary shape selection. It is suitable for the needs of processing manufacturers such as shoe uppers, shoe materials, leather goods, handbags, bags, and leather clothing.

What You Should Know About Laser Paper Engraving Machine?

A paper laser engraving machine can be used to etch & engrave letter, number, text, sign, logo, picture, pattern or cut profiles & shapes with papers, including cardboard, card stock, construction paper, bond paper, fish paper, rice paper, matboard, coated paper, kraft paper, silk paper, vellum, copy paper, and synthetic paper. A paper laser engraver is also known as paper laser etching machine, laser paper engraving machine.

Paper laser engraving has the incomparable superiority of ordinary die stamping processing methods: firstly, it is non-contact processing, no direct impact on paper products, so there is no mechanical deformation; secondly, there is no die "tool" wear during laser paper engraving. Therefore, the loss of paper materials is small, and the product defect rate is extremely low. Moreover, in the laser paper engraving process, the laser beam energy density is high, the processing speed is fast, and it is local processing, which has no or minimal impact on the non-laser irradiated parts of the paper.

Many commodities need wrapping paper for packaging, and the wrapping paper needs to be provided with patterns and text to beautify and identify. At present, most of the patterns and texts on the packaging paper are printed on the packaging paper by the plane printing process, but the patterns and texts printed by the plane printing process have no three-dimensional effect and have a poor perception of users. Moreover, when printing in small batches, the cost is high. It is also higher, so we can use CO2 laser beam to engrave patterns and text on the packaging paper. The cost of laser paper engraving is lower, and for small batch processing, the cost is lower.

What You Should Know About Laser Fabric Engraving Machine?

A fabric laser engraving machine can be used to etch & engrave signs, texts, logos, numbers, letters, patterns, pictures or cut profiles & shapes with fabrics & textiles, including jeans, cotton, aramid fibers, denim, fleece, felt, nylon fabrics, tackle twill, and polyester. A fabric laser engraver is also known as laser fabric etching machine, laser textile engraving machine, laser jeans engraving machine.

Garment Laser Engraving Machine Embroidery

Most of the textile and apparel fabrics can be made of various digital patterns using laser fabric engraving machines. The traditional textile fabric production process requires post-grinding, hot embossing, embossing and other processing treatments, while the laser textile engraving machine burns in this respect has the advantages of convenient and fast production, flexible pattern change, clear images, strong 3D impression, and can fully express The natural texture of all kinds of fabrics, and the advantages of long-lasting and ever-changing. If combined with the hollowing process, it is the finishing touch and complements each other. Apparel fabrics and garment laser embroidery are suitable for: textile fabric finishing processing plants, fabric deep processing plants, ready-to-wear garment plants, surface accessories and processing enterprises with supplied materials.

Denim Jeans Image Laser Spray

Through the laser irradiation of the laser jeans engraving machine, the dye on the surface of the denim fabric is vaporized, so that non-fading image patterns, gradual flower shapes, cat whiskers frosting and other effects can be produced on various denim fabrics, adding new beauty to denim fashion. Laser jeans engraving machine denim spray processing is an emerging processing project with substantial processing profit and market space. It is very suitable for denim garment factories, washing plants, processing enterprises and individuals to carry out value-added deep processing of denim products.

Features of Laser Engraving Machine for Leather, Fabric, Jeans, Paper

1. High stability and high strength mechanical structure casted by high accuracy model which can ensure stable data motion, high speed, high precision, long-term operation without adjustment and the same precision carving. The design idea of around the body through can add materials from before and behind which for infinite workpiece.

2. The CO2 laser engraver machine adopts advanced DSP digital control system, international standard laser power supply, integrated framework style, high stability, high-speed USB 2.0 interface output can support off-line working.

3. Transmit files directly from Coredraw, AutoCAD.

4. Optimization of mechanical and electrical design, low noise.

5. Big power and high stability laser tube, imported lens and mirror, long life span.

6. Imported linear rail and high quality tapes for transmission, equip speed-down structure, ensure high quality and high stability cutting.

7. Automatic up-down table, rotary device, red dot position, Z axis for option.

Applications of Laser Engraver for Jeans, Leather, Fabric, Paper

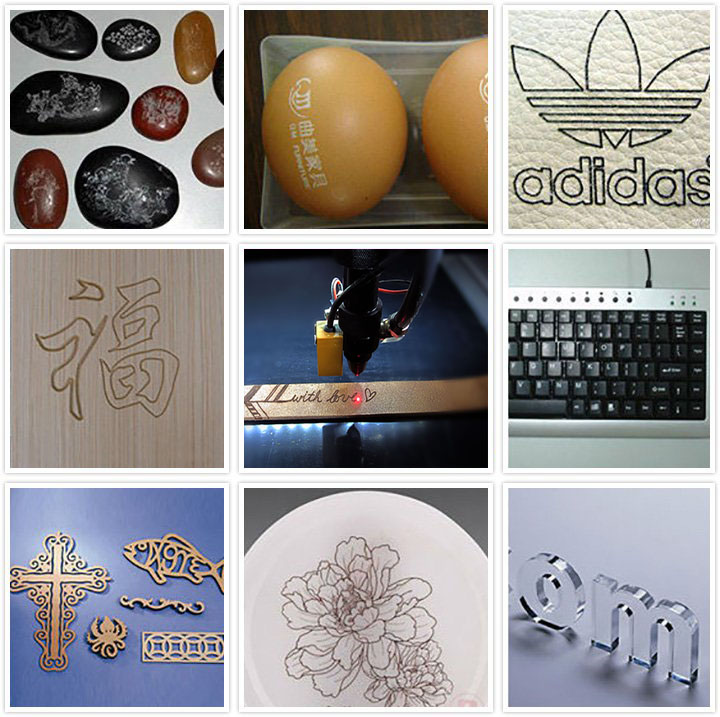

As a brand-new processing method, laser engraving has gradually been widely used in the leather, fabric, textile, paper, and clothing industries due to its advantages of precise processing, fast processing, simple operation, and high degree of automation.

Applicable Materials: Leather, fabric, textile, cloth, jeans, glass, organic glass, acrylic, wood, MDF, PVC, plywood, maple leaf, double-color board, bamboo, plexiglass, paper, marble, ceramics and more materials.

Applicable Industries: Monument/Gravestone/Tombstone industry, garment industry, model industry, construction models, aviation and navigation models and wooden toys, advertisement, decorations, arts, crafts, electronics, electric appliances and more industries.

Technical Parameters of Laser Engraver for Leather, Paper, Fabric, Jeans

| Model | STJ1390-2 |

| Working Area | 1300mm*900mm |

| Laser Power | 60W (80W, 100W, 130W, 150W for option) |

| Laser Type | CO2 glass laser tube |

| Compatible Software | LaserWorks V8 |

| Position System | Red dot |

| Interface | USB |

| Support Graphic Format | AI, PLT, BMP, DXF, etc. |

| Driving Mode | Stepper motor |

| Cooling Mode | Circulation water cooling |

| Venting Attachments | Air exhaust fan with venting tube |

| Working Voltage | AC 110 - 220V±10%, 50 - 60Hz |

| Driving System | Nema stepper |

| Option | Motorized Z axis table |

| Option | Rotary attachment for column materials |

Details of Laser Engraver for Fabric, Jeans, Leather, Paper

Affordable Laser Engraver Projects & Plans

Laser Engraving Cutting Projects for Leather, Fabric, Paper, Jeans

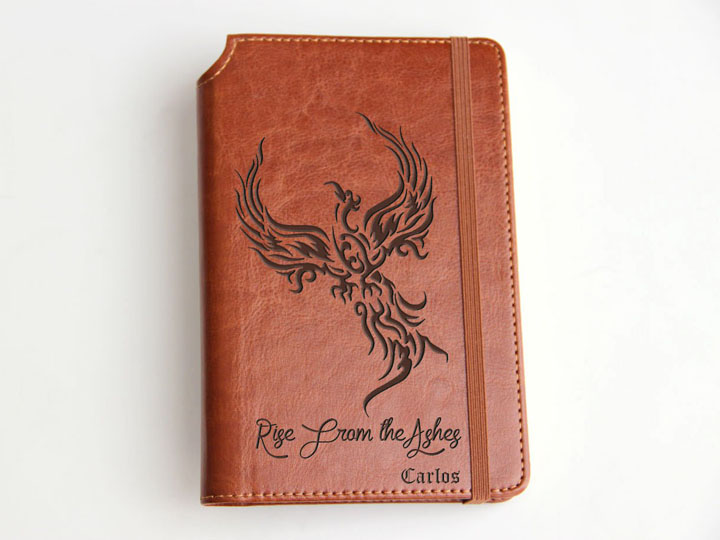

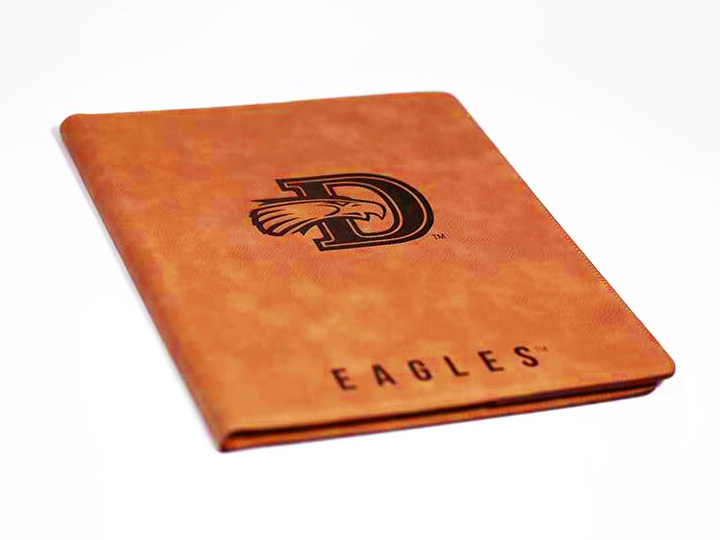

Laser Engraving Leather Ideas & Projects

Laser engraving genuine leather and synthetic leather (leatherette) projects and ideas.

Laser Engraved Genuine Leather Journals

Laser Engraved Synthetic Leather Wallets

Laser Engraved Leatherette Logo Coaster

Laser Engraved Custom Genuine Leather Keychain

CO2 Laser Engraved Genuine Leather Belt

Laser Engraved Personalized Leather Bags

Laser Engraved Personalized Leather Baseball Gloves

Laser Engraved Custom Leather Card Holders

Laser Engraved Leather Motorcycle Jacket

Laser Engraved Personalized Leather Patches

CO2 Laser Engraved Leather Labels

Laser Engraved Personalized Leather Portfolio with Notepad

CO2 Laser Engraved Leather Tags

Laser Engraving Fabric & Textile Projects & Ideas

CO2 Laser Engraving Fabric Ideas

CO2 laser engraving is effective for fabrics with a pile or non-woven fabrics.

Laser Engraved Textile Projects

Including leather, micro-fiber, synthetic fibers and cotton.

Laser Etching Textile Ideas

Laser etching is a unique application that uses laser beam to remove a thin layer of pigment or fiber dye from the textile.

Laser Engraved Jeans Projects

The laser engraved patterns look like naturally faded jeans.

Laser Engraving Pattern on Denim Jeans

Laser etching for jeans denim, t-shirt denim, sean denim, and denim beach bag with excellent results.

Laser Engraving Paper Ideas & Projects

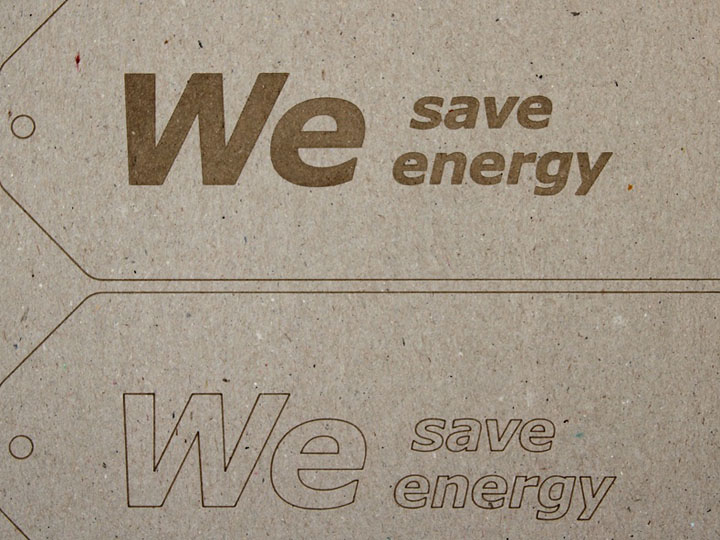

Laser Engraving Cardboard Projects

Laser engraving & cutting cardstock, paper, cardboard, and chipboard.

Laser Engraved Card Box Projects

Personalized with logos, dates, letters, texts, names, graphics, patterns, and photos.

Laser Etching Corrugated Cardboard Box Ideas

For natural and corrugated cardboard varieties, prototyping, and packaging.

Packages of Laser Engraving Machine for Paper, Leather, Textile, Jeans

Jane

The more impressive thing for me was the detail that this thing is capable of. I can literally engrave fonts that are around size 8 and they burn crystal clear with my settings. I suggest doing a lot of experimenting because in the end, once you get the right calibration, this thing is capable of incredible detail and quality engravings. You may also want to mess around with the contrast settings if you are engraving complex images. For tiny details, you may want to try using the lowest possible settings in the laser power and laser engraving depth.

Frank Herrmann

Andrei Capitan

Acest gravor laser este bine construit și ambalat. A ajuns într-o săptămână sau cam asa ceva. Majoritatea pieselor sunt preasamblate și pot fi instalate în câteva minute, ceea ce este un mare plus în comparație cu unele dintre kituri.