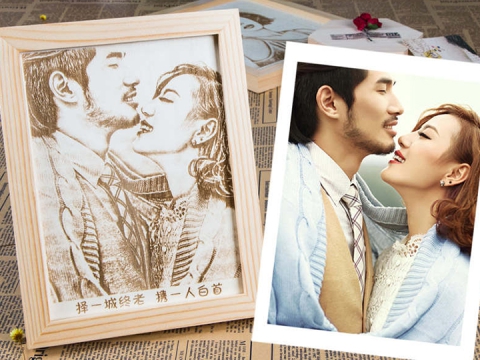

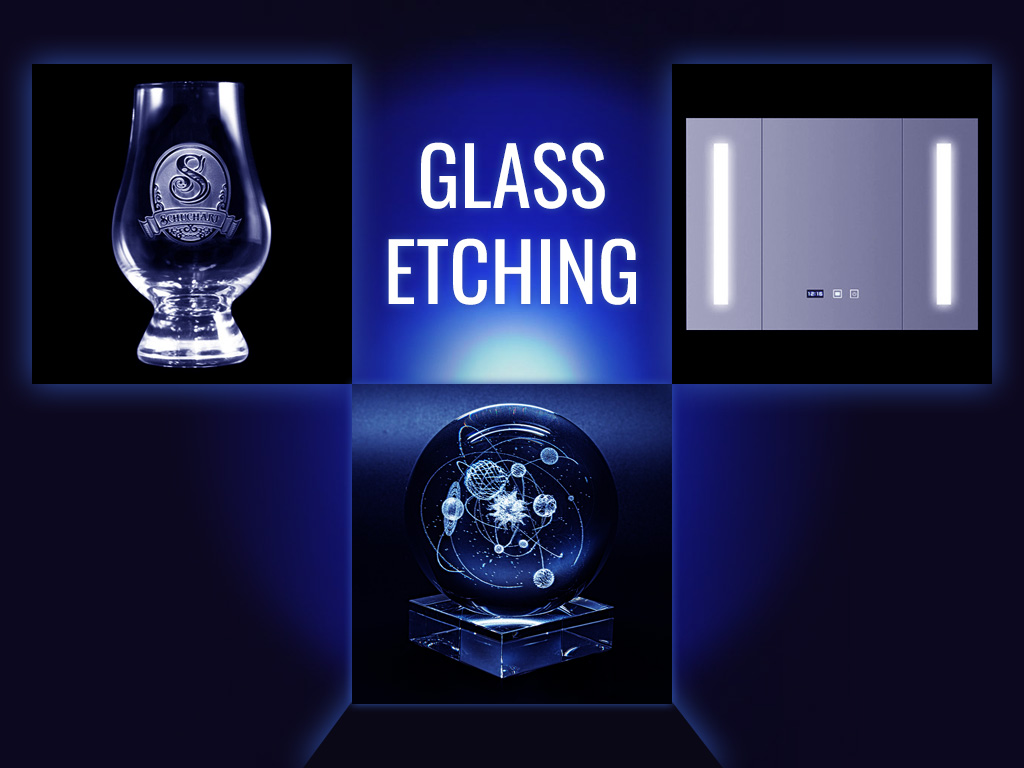

Glassware is being sought after by people. Ordinary glass is endowed with fine lines and becomes an artistic decoration. The magical patterns on the glassware design are not from artificial engraving, but from the charm of technology - laser etching machine.

As we all know, laser etching machine can be used for engraving various materials, but how to use laser to etch fragile materials such as glass, crystal and ceramics is a problem. What laser etcher should be chosen to engrave glassware so as to form beautiful patterns and texts without breaking the glass? Let's start understanding.

Introduction

At present, there are five common laser glass etching machines on the market, CO2 laser engraving machines, CO2 laser marking machines, UV laser marking machines, UV laser subsurface engraving machines, and fiber laser marking machines.

For different types of glass, the lead content is different, and the etching method is also different. As the lead content increases, the hardness and high temperature viscosity of the glass decrease, and the glass is more easily broken. Ordinary glass can choose low-cost CO2 laser etcher. Due to the high lead content and low hardness and viscosity of crystal glass, only UV laser etcher can be used to achieve perfect results. The fiber laser etching machine can only achieve paint stripping or coating removal from glass.

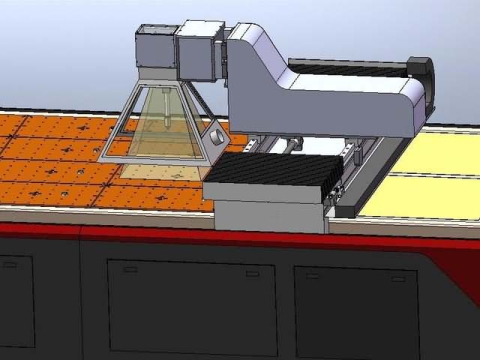

CO2 Laser Glass Engraving Machine

The CO2 laser engraving machine uses a CO2 sealed laser tube to etch the glass surface. It can etch on the large-format glass surface. The most common table sizes are 400mm x 600mm, 600mm x 900mm (2' x 3'), 900mm x 1300mm, 1300mm x 2500mm (4' x 8'), 1500mm x 3000mm (5' x 10'), you can choose based on your business needs. Generally, the laser can form frosting or shattering effect on the glass surface. Usually users want to get frosted rather than broken effect, which depends on the texture of the glass and whether the hardness is consistent.

CO2 laser glass engraver costs anywhere from $3,000 to $5,500 based on different configurations.

CO2 laser etched glass projects can be made with a smoother frosted surface if you follow the three steps:

Step 1. Apply a little wash to the area to be etched, find a piece of newspaper or napkin that is slightly larger than the area to be etched, soak the paper completely with water, squeeze the excess water, and place the wet paper on the etching area. Flat without wrinkles.

Step 2. Put the glass in the machine, work while the paper is still wet, then take out the glass, remove the remaining paper, and then clean the glass surface.

Step 3. If desired, lightly polish the glass surface with 3M Scotch-Brite. In general, the laser power should be set lower, the precision should be set at 300dpi, and the engraving speed should be faster. You can try to use large-sized lenses for engraving.

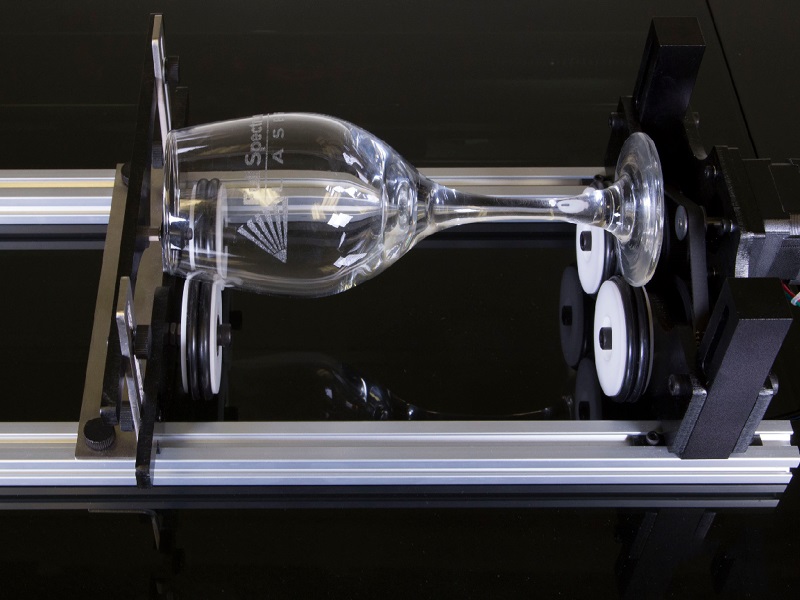

CO2 Laser Engraved Glass with Rotary Attachment

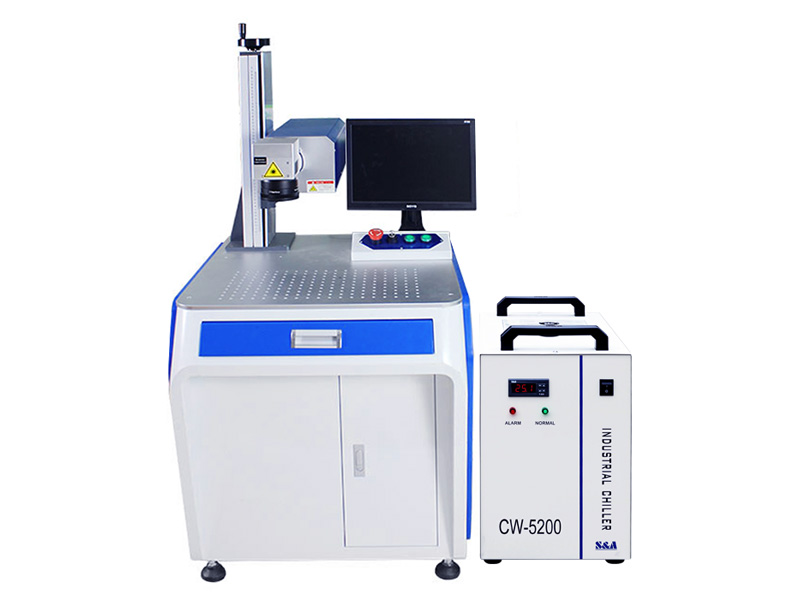

CO2 Laser Glass Marking Machine

Compared with ordinary glass etching methods, CO2 laser marking technology has high processing efficiency, fast speed, beautiful and detailed marking products, and does not require material consumption, environmental protection, energy saving, and convenient maintenance. It is the best choice for etching glass products. The disadvantage is that the marking area is up to 300mm x 300mm.

CO2 laser glass markers have a price range from $4,400 to $8,000.

CO2 laser glass marking machine is a laser galvanometer marking machine that uses CO2 gas as the working medium. CO2 and other auxiliary gases are charged into the discharge tube and high voltage is applied to the electrode, and a glow discharge is generated in the discharge tube, so that the gas emits a laser beam with a wavelength of 10.64um, and the laser energy is amplified, with the galvanometer scanning and the F-Theta mirror focusing, the computer will drive the laser marking control card to etch photos, characters, numbers and lines on the glass surface based on the user's requirements.

CO2 Laser Marked Glass

UV Laser Glass Marking Machine

UV laser markers provide clear, long-lasting etching on virtually any color or type of glass bottle, so there are no glass breakage consequences. Ultraviolet laser marking machine is also called cold light laser marking. It adopts ultraviolet laser with wavelength of 355um, which has smaller diameter of focusing spot, more precise marking effect, and high absorption rate of ultraviolet light to engrave on metal or glass materials. UV laser marking on flat glass is directly related to the peak power of the laser, the size of the final focused spot, and the speed of the galvanometer. Ultraviolet laser marking machine has unique and superior performance, which is very suitable for laser etching of glass bottles. It provides greater quality with efficiency, clear, durable coding on virtually any color or type of glass bottle, and is designed for high-quality marking with virtually no font, coding or graphic restrictions.

UV laser glass etching machine is priced from $6,400 to $30,000.

UV Laser Engraved Wine Glass

3D Subsurface Laser Glass Etching Machine for Crystal

Speaking of laser subsurface engraved glass. Most of people may not be particularly familiar with this. In fact, it is a new type of building material product based on electronic technology, laser technology and LED technology. It can be used for inside glass etching, inner crystal engraving, and internal acrylic marking, which is used to DIY custom trophies, bubblegram, names, portrait, and more personalized gifts with 3D subsurface laser crystal engraving business, ideas, projects, and plans. It can also used for shower rooms, sliding doors, KTV, bars, tea restaurants, chain stores, night scenes, zoning and background applications, home and art photo browsing, and industrial glass production design. Let's take a look at the advantages and applications of laser etching art glass.

The laser energy density of the etched glass must be greater than a specific critical value or threshold for breaking the glass. For the laser energy density at a particular point is related to the size of the spot at that point, for the same laser, the smaller the spot is, the higher the energy density will be, then when properly focused, the laser can enter the glass and reach the processing area before the glass damage threshold . When the desired processing area exceeds this critical value, the laser pulses for a short period of time, and then its energy immediately ruptures the crystal due to overheating, creating a white spot, which then engraves a predetermined shape within the glass. Laser interior engraving uses a laser beam to etch the interior of glass. No dust, no volatiles, no emissions, no consumables, and no pollution to the external environment. This is unmatched by traditional engraving, and the working environment of workers has been greatly improved. In addition, the degree of automation is high, after the glass project is put on the machine, the entire production process is controlled by the computer with automation. Compared with the traditional sandblasting engraving, the labor intensity of workers is greatly reduced. Therefore, the production of laser engraved glass is relatively easy to achieve standardized, digital and networked production, and it can also achieve remote monitoring and operation, with a lower overall cost.

3D subsurface laser glass etching machine starts around $17,900, and the higher-end type costs around $22,000.

Laser subsurface engraving will be a revolutionary change in the craft glass deep processing industry. It is energy efficient, environmentally friendly and highly automated. It enables standardized, digitized and networked production, as well as remote monitoring and operation. This will greatly reduce the labor intensity of workers, and improve efficiency & quality. It is an ideal upgrade to traditional glass etching technology.

Laser internal engraved glass is widely used in night scenes, KTV, bars, private clubs, and even a larger range, nothing is impossible, only you can't think of it. By using ultra-clear glass and laser etching, you can experience it perfectly, whether it is a coffee table, advertising board or small application like mosaic.

3D Subsurface Laser Engraved Crystal Glass

Due to the high light transmittance and the advantages of safety and beauty, laser engraved art glass has been widely used in architectural glass curtain walls, KTV, bars, nightclubs and other backgrounds, floors, partitions.

Fiber Laser Glass Etching Machine

Fiber laser glass etcher uses a 10.64um laser emitted by a fiber laser after a series of treatments. After being focused by a lens, the energy is highly concentrated in a small range, and the paint or coating on the glass is removed to instantly form the required graphics. It is mainly used for glass decoration with light strips. The table sizes can be customized as your requirements up to 2000mm x 4000mm (6' x 12').

Fiber laser glass etcher has an affordable price range from $3,900 to $12,800.

Fiber Laser Etched Mirror Cabinet with Light Strip

No matter which laser engraver you choose, you can add an additional rotation axis to achieve etching on glass tubes, bottles, wine glasses, drinking glasses, cups, and coffee mugs.

Things To Consider

You should be more careful when engraving lead-containing crystals with a laser engraver. Lead-containing crystals have different expansion coefficients from ordinary crystals, which may cause crystal cracks or breakage during etching. Smaller power settings can avoid this problem, but you should always be prepared for any breakage.

If the glassware needs to be sandblasted, the laser etching machine can also quickly make the right engraving template: Apply the protective coating directly to the glassware, and then use the laser etcher to trace the pattern.

If you are processing hemispherical glass, you must choose a longer focusing wavelength. Because the longer the focusing wavelength, the larger the working area. Then position the focus point in the center, so that the periphery of the focus point can get a good etching effect.

Cleaning: Use a damp fabric to clean the surface after etching.

Coloring: It can be colored with acrylic paint.