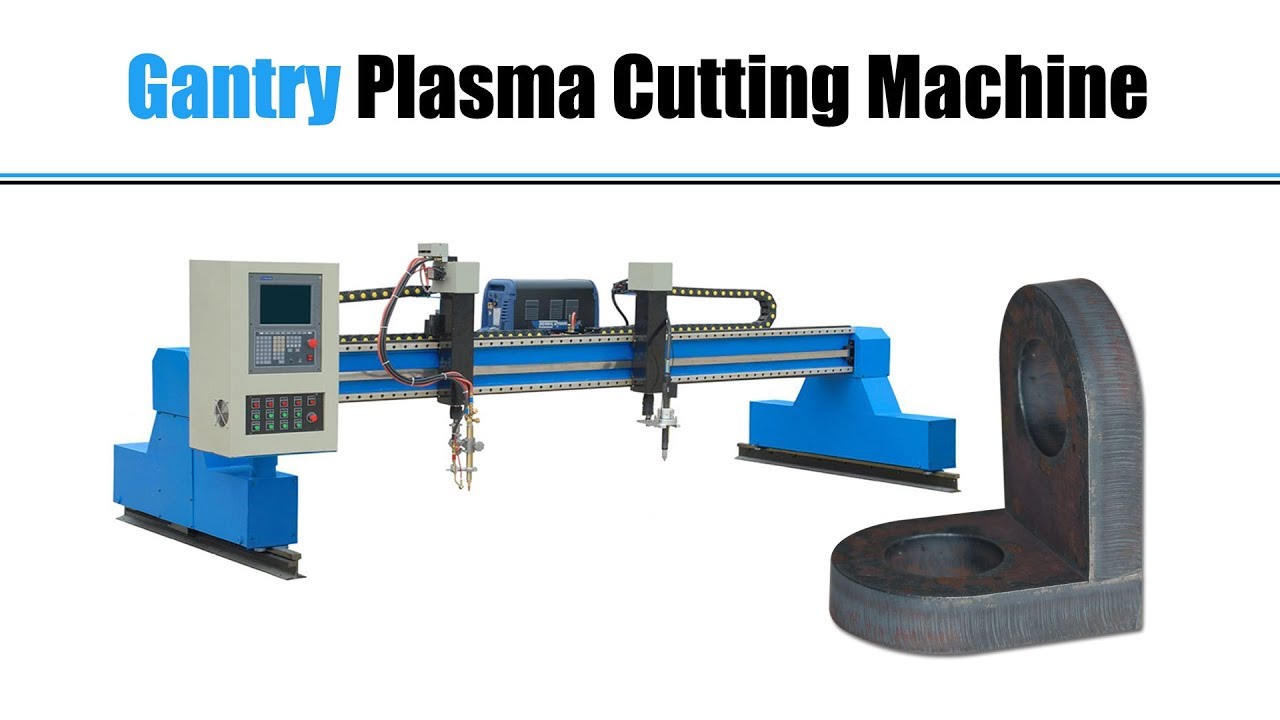

Industrial Large Gantry Plasma Cutting Machine for Sale

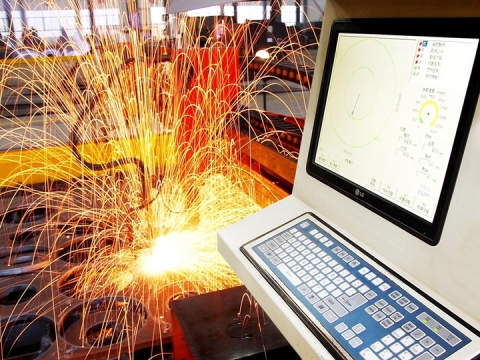

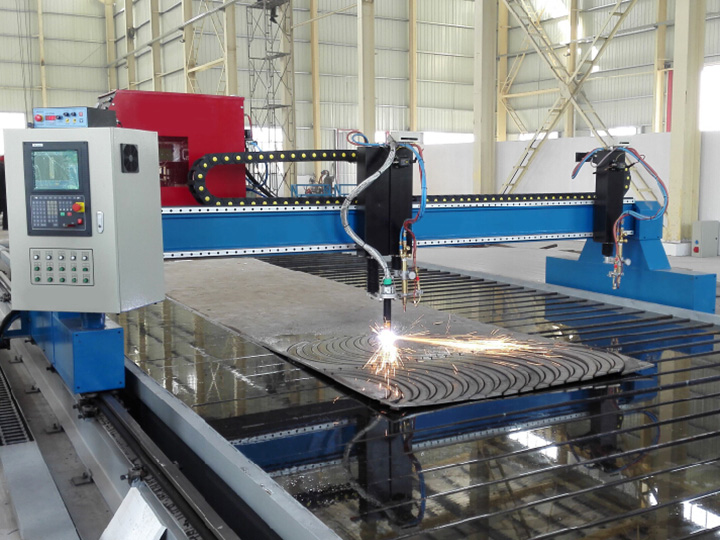

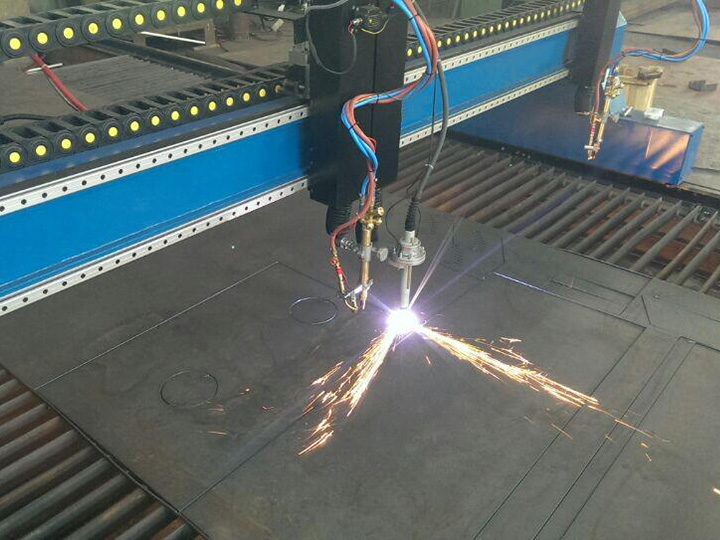

Industrial gantry plasma cutting machine is designed for large format sheet metal fabrication, the industrial plasma system is used to cut mild steel with flame cut and cut high carbon steel, stainless steel, aluminum, copper and other non-ferrous metal with plasma cut. Now the industrial gantry CNC plasma cutter for sale at cost price.

- Brand - STYLECNC

- Model - STP3000-G

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Plasma Cutter

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

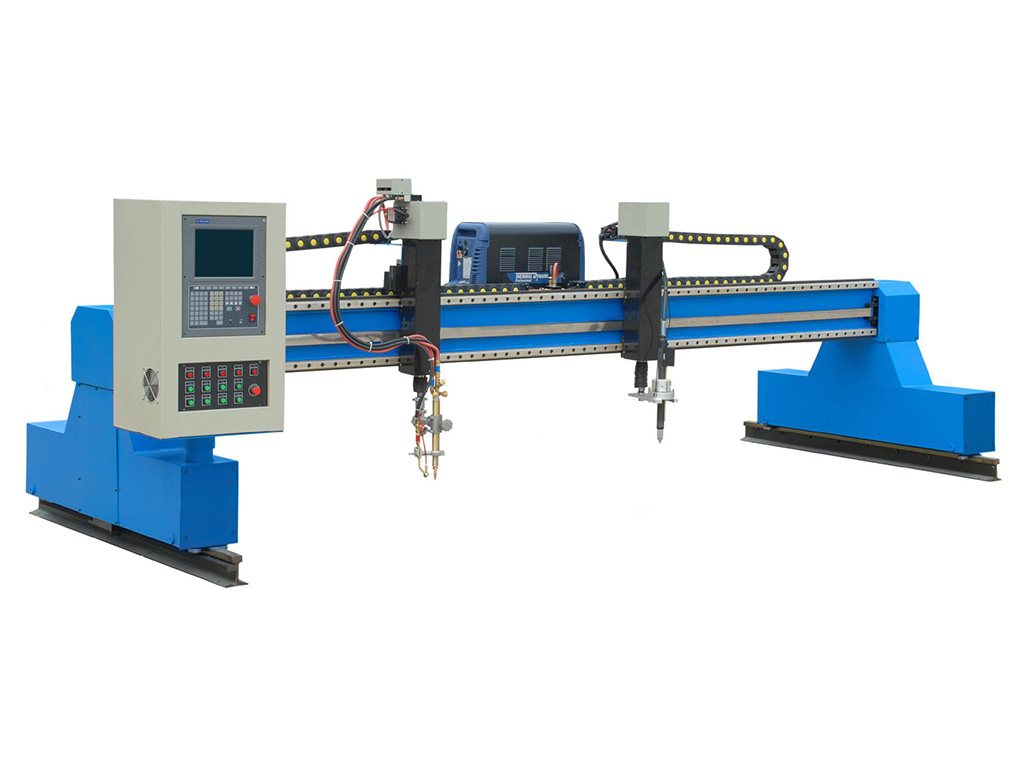

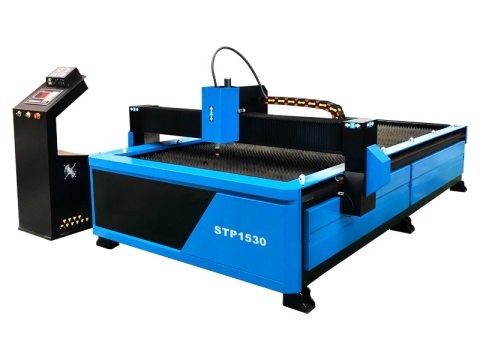

A large gantry industrial plasma cutting machine is specially designed for sheet metal fabrication, it is characterized by high automation and efficiency, easy operation, and long service time. This industrial plasma cutter has a gantry structure with a double-driven system, working size can be customized upon requirements. It can be used for cutting carbon steel, stainless steel, and non-ferrous metal in any 2D graphics. The gantry CNC plasma cutting machine is widely used in sheet metal cutting fields.

CNC plasma gantry kit comes with a simple structure, convenient adjustment, and precise control. It can realize horizontal and vertical movement separately or in conjunction, and can easily form a variety of processing tracks to meet the processing needs of different workpieces. It has a wide cutting range, great flexibility, and adjustment space. The height of the cutting torch in the vertical direction can be precisely adjusted to meet the height setting requirements of different processes. Due to the large span of the gantry, a bilateral drive is adopted laterally to make the movement stable.

CNC plasma table gantry kit is bidirectionally supported, the force is more uniform, the equipment has good rigidity, and can achieve a large lateral span, usually up to 3 to 10m. However, the equipment installation requirements are high, the structure is relatively large, and it takes up more plant area. The driving mode is divided into unilateral driving and bilateral driving. Unilateral drive and bilateral drive each have their characteristics and applications. The unilateral drive avoids the high-precision synchronous control and complicated structure of the bilateral drive. However, due to the offset of the center of mass and the driving force not passing through the center of mass, asymmetric inertial force will be generated during operation, which is prone to vibration, deformation, and tilt. Therefore, it can only be used in a small span. The double-sided drive structure is relatively complicated and requires high-precision synchronous control on both sides, which can be used for a larger span and more stable movement.

Features of Industrial Gantry Plasma Cutting Machine

1. Steel hollow beam design ensures good heat dissipation without deformation.

2. The gear-rack driving motions without an engagement gap ensure the machine runs smooth at high speed.

3. Fully functionalized CNC controller and optocoupler device enhance the super anti-jamming capability of the plasma cutting system.

4. The world's top branded components and circuits ensure long service life.

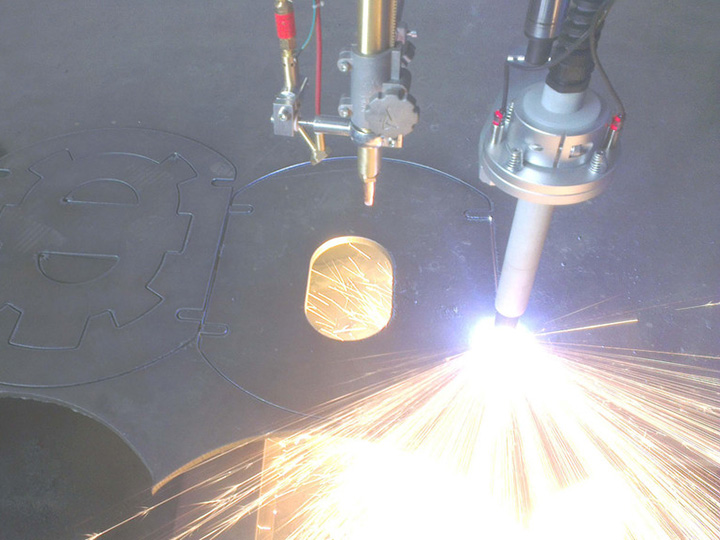

5. Multiple cutting torches can be configured. Both flame and plasma torches are optional to meet the needs of cutting different materials in a range of thicknesses.

Technical Parameters of Large Gantry Industrial CNC Plasma Cutting Machine

| Model | STP3000-G |

| Cutting Area | 3000mm |

| Input Power | 220 ± 10%V AC 50Hz /60 Hz |

| Cutting Modes | Plasma Cutting / Flame Cutting / Plasma Cutting+ Flame Cutting |

| Transmission Style | Rack&Gear |

| Drive Style | Stepper Motors Servo Motors for option. |

| Torch Lift Distance | 200MM |

| Torch&Number | One Plasma Torch / One Flame Torch. One Plasma Torch + One Flame Torch. Two Flame Torches/One Plasma Torch + One Flame Torch. |

| Plasma Cutting Thickness | Depend On Plasma Source |

| Torch Height Control | Plasma Automatic Torch Height Control. Flame Capacitance Torch Height Control. |

| Cutting Speed | For Servo Motors: 0 - 10000 mm/min For Step Motors: 0 - 4000 mm/min |

| Cutting Table | Standard cutting table. Workpiece collects drawer cutting table. Smoke and dust collector with workpiece collect drawer cutting table. We can supply a drawing of the cutting table with the machine for free. |

Industrial Large Gantry CNC Plasma Cutting Machine Applications

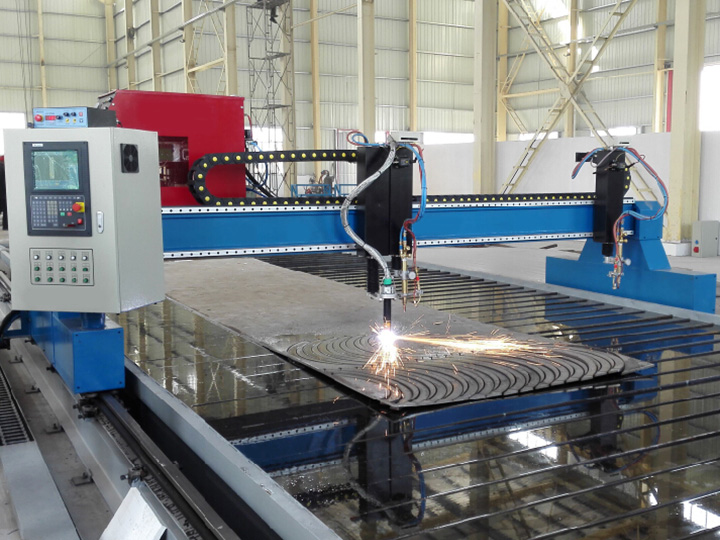

Industrial large gantry plasma cutter with big size can cut mild steel with flame cutting and cut high carbon steel, stainless steel, aluminum, copper, and other non-ferrous metal with plasma cutting, it can be configurated as your request, thus it is widely applied in industries such as machinery, automobile, shipbuilding, petro-chemical, war industry, metallurgy, aerospace, boiler and pressure vessel, locomotive, etc.

Large Gantry Industrial CNC Plasma Cutter Projects

Package of Large Gantry Industrial Plasma Cutter

Key Considerations When Choosing an Industrial Gantry Plasma Cutting Machine

When investing in an industrial gantry plasma cutting machine, it’s essential to make an informed decision based on the specific needs of your business. With many factors influencing performance, accuracy, and cost, understanding the key considerations can help you make the best choice. Here’s a guide to what you should keep in mind when selecting a plasma-cutting machine.

Cutting Thickness and Material Type

Consider the thickness and types of materials you need to cut. Gantry plasma cutters are capable of handling a wide range of materials, but the cutting power should match your requirements. Choose a machine with the appropriate amperage and power settings for the thickness and type of material, whether it’s steel, aluminum, or other metals.

Precision and Cutting Accuracy

Accuracy is crucial in industrial applications. Look for a gantry plasma cutting machine with high precision capabilities to ensure consistent and detailed cuts. A machine with fine control over cutting speed, height, and other parameters will help achieve the accuracy needed for complex parts and intricate designs.

Speed and Productivity

The speed of the plasma-cutting machine affects your overall productivity. If your operation demands high-volume cutting, selecting a machine with faster cutting capabilities will help increase efficiency. Faster cutting reduces production times and improves throughput, which is essential for meeting tight deadlines.

CNC Control System and User Interface

A user-friendly control system is essential for ease of operation. Modern gantry plasma cutters come with advanced CNC systems that allow operators to make precise adjustments to cutting paths, speeds, and other parameters. Choose a system with an intuitive interface to streamline operations and reduce the learning curve for your team.

Machine Durability and Build Quality

The durability of the machine’s frame and gantry system will significantly impact its performance and lifespan. Choose a machine with a sturdy, high-quality build to ensure stability during cutting and minimize wear and tear. This helps maintain consistent performance over time, reducing maintenance costs and downtime.

Support and After-Sales Service

Reliable after-sales support and service are key when choosing an industrial plasma cutter. Look for a manufacturer that offers strong customer support, regular maintenance options, and readily available spare parts. A good service plan ensures your machine remains in optimal working condition, helping to reduce operational disruptions.

How a Dual-Torch Setup Can Improve Cutting Efficiency in Large Gantry Plasma Cutters?

A dual-torch setup in large gantry plasma cutters can significantly improve cutting efficiency by allowing two torches to operate simultaneously, cutting multiple parts or different sections of material in one pass. This dual capability reduces machine idle time, increasing overall productivity.

With two torches, operators can cut two pieces at the same time or tackle larger projects without needing to reset or reposition the workpiece. This not only speeds up the cutting process but also ensures a smoother workflow, especially for high-volume tasks.

In addition to increased speed, dual-torch setups also help in reducing material waste. By optimizing torch paths, the machine can minimize spacing between cuts, ensuring that more material is used efficiently. Overall, a dual-torch gantry plasma cutter enhances versatility, cuts down on operational time, and improves cost-effectiveness, making it an excellent choice for businesses aiming to boost productivity without compromising on cut quality.

The Importance of Customizable Cutting Areas for Large-Scale Projects

Customizable cutting areas are a vital feature for large-scale projects, especially when working with diverse materials and varying sizes of workpieces. By tailoring the cutting area to specific needs, manufacturers can increase productivity, flexibility, and precision. Here’s why this feature is so important:

Flexibility for Diverse Projects

One of the biggest advantages of a customizable cutting area is the flexibility it provides. In large-scale operations, the types of materials and dimensions can vary greatly. A cutting area that can be adjusted to accommodate different sizes ensures that you can handle a range of projects, from small components to large, intricate pieces, without needing to invest in multiple machines.

Maximizes Material Utilization

With a customizable cutting area, you can optimize material usage, reducing waste. By adjusting the cutting zone to fit the dimensions of your material, you can reduce unused space and cut more parts from a single sheet. This optimization leads to cost savings and more efficient production cycles.

Increased Throughput and Speed

Larger cutting areas allow for the simultaneous cutting of multiple parts, reducing the number of steps required in the production process. This setup enables you to work on several pieces at once, improving throughput and speeding up production times. It’s especially beneficial for mass production or projects that require high-volume output.

Precision and Accuracy in Large Projects

Customizable cutting areas contribute to precision by allowing the workpiece to fit perfectly within the cutting zone. This ensures that cuts are made exactly where needed, reducing errors. Having the ability to adjust the workspace also means fewer material shifts, keeping the project aligned and preventing potential misalignments during the cutting process.

Improved Efficiency and Productivity

By adapting the cutting area to the specific requirements of each project, manufacturers can reduce downtime and improve overall machine efficiency. Customization ensures that the cutting system can meet varying demands without significant setup changes, leading to more streamlined workflows and better productivity.