Top Rated Fiber Laser Cutter Machines for Metal Fabrication

This video will show you what is a fiber laser cutter? how does fiber laser metal cutting machine cut sheet metals & tubes? how to choose and buy?

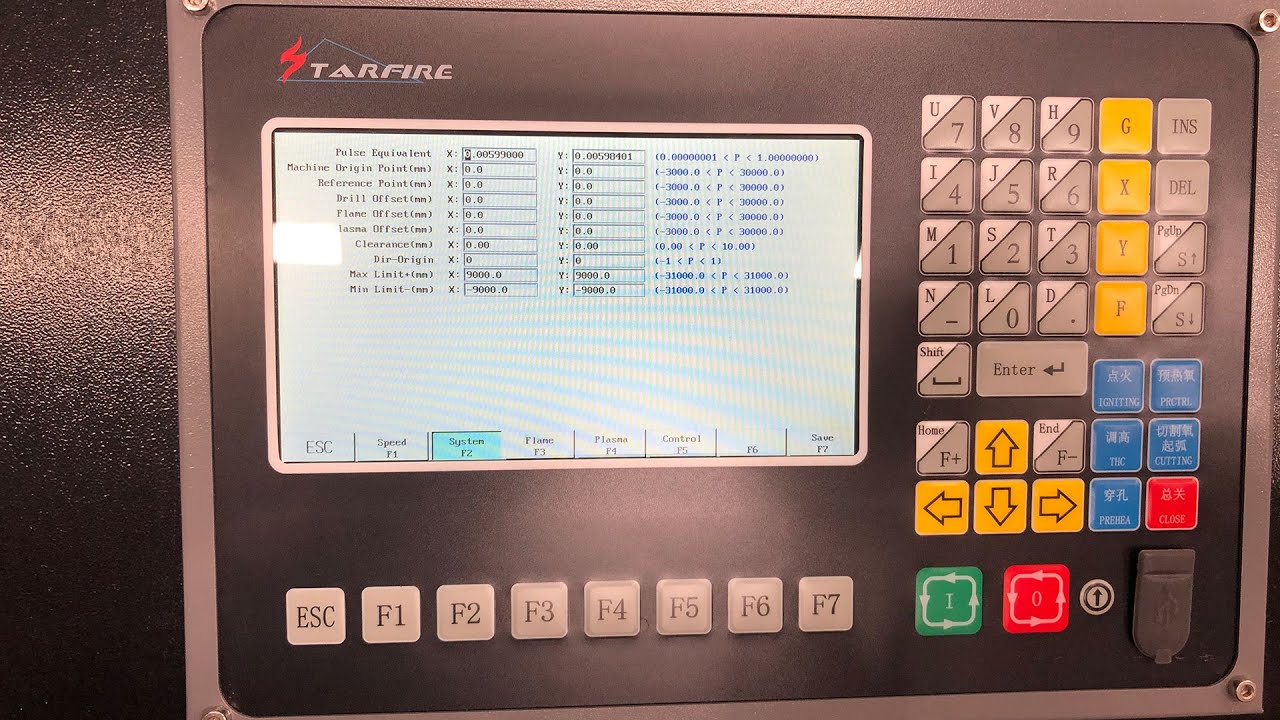

This video will show you how to use a CNC plasma cutter with STARFIRE controller for sheet metal fabrication. The controller for sheet metal cutting only, if your machine with rotary device to cut metal tube, please contact us for another video.

CNC plasma cutter can be equipped with different power supply, such as Chinease Huayuan 63A, 100A,120A, 160A and 200A for cutting metals with different thickness. In this video we will show STP1530 CNC plasma table with 120A Huayuan plasma power supply cutting 8mm carbon steel. If you are a beginner, please keep patience and adjust the cutting parameters little by little.

The CNC plasma cutting machine has excellent adaptability for cutting processing of various metal materials, and can basically complete the cutting of all conductive metal materials, such as copper, aluminum, stainless steel, and galvanized sheets. In the actual processing and production, there are differences in the operation of using plasma cutting machines for cutting materials of different materials. Including the cutting speed, output current size, cutting torch height and other parameter settings are more or less different, the purpose of adjustment is to optimize the final cutting quality.

Regarding the cutting of different metals by CNC plasma cutter tables, STYLECNC has summarized some common solutions:

1. Select the appropriate gas flow and cutting speed.

2. Ensure that the plasma arc power can be met.

3. Ensure the concentricity of the electrode nozzle.

This video will show you what is a fiber laser cutter? how does fiber laser metal cutting machine cut sheet metals & tubes? how to choose and buy?

This coil-fed laser blanking system allows metal manufacturers to continuously cut parts from coil metal with auto feeder, enabling flexible metal fabrication.

You will understand how does a CNC plasma table cut 15mm carbon steel from this video. This is a helpful guide to buy the best CNC plasma cutting table.