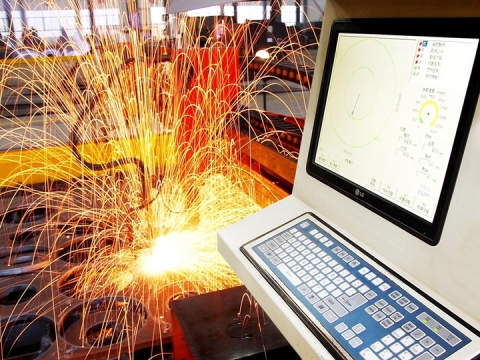

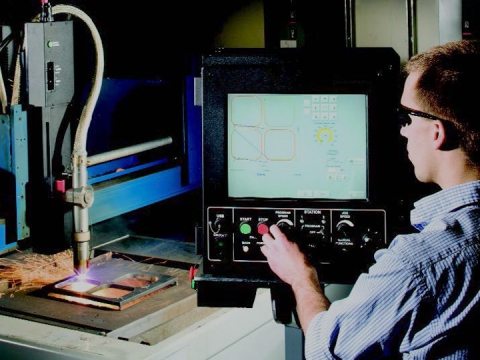

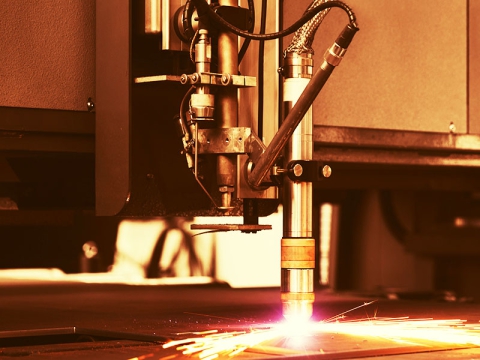

What Is CNC Plasma Cutter and How Does it Work?

The combination of plasma cutter and CNC controller is called CNC plasma cutting machine. The CNC plasma cutter combines a simple and easy-to-use CNC system to ionize the high-speed airflow ejected from the nozzle at high temperature to form electrical conductors. When the current passes through, the conductor forms a high-temperature plasma arc, and the heat of the arc causes the metal at the incision of the workpiece to locally melt (and evaporate), and the molten metal is removed by the power of high-speed plasma airflow to form a processing method of the incision. The elongated and stable plasma arc formed by annular gas flow technology ensures smooth and economical cutting of any conductive metal.

Problems & Solutions

In the process of operating the CNC plasma cutter machine, you will encounter various failures. In the face of problems, the operator should first keep calm, analyze the causes of the failures combined with the symptoms of the problems, and find solutions for troubleshooting.

Working air pressure too low.

When the plasma cutter is working, if the working air pressure is much lower than the air pressure required by the manual, it means that the ejection speed of the plasma arc is weakened, and the input air flow is less than the required value. At this time, a high-energy, high-speed plasma arc cannot be formed. As a result, the incision quality is poor, the incision is not penetrated, and the incision is accumulated. The reasons for insufficient air pressure are: insufficient air input from the air compressor. The pressure regulation of the air regulating valve of the cutter is too low, there is oil pollution in the solenoid valve, and the air path is not smooth. Therefore, it is necessary to check from these aspects one by one, and find problems and improve them in time.

Working air pressure too high.

If the input air pressure is too high, after the plasma arc is formed, the excessive airflow will blow away the concentrated arc column, disperse the energy of the arc column, and weaken the cutting strength of the plasma arc. The main reasons are: improper adjustment of the input air, excessive adjustment of the air filter pressure reducing valve or failure of the air filter pressure reducing valve.

Improper installation of wearing parts such as electrode nozzles.

The electrode nozzle is threaded and needs to be screwed into place. Improper installation of the nozzle, such as the screw thread is not tightened, and the eddy current ring is not installed properly, it will cause unstable cutting and damage to the wearing parts too quickly.

Input AC voltage is too low.

Before commissioning and use, check whether the power grid connected to the plasma cutting machine has sufficient carrying capacity and whether the specifications of the power cord meet the requirements. The installation location of the plasma cutting machine should be far away from large electrical equipment and places with frequent electrical interference.

Poor contact between ground wire and workpiece.

Grounding is an essential preparation before cutting. If no special grounding tool is used, there is insulation on the surface of the workpiece, and long-term use of the ground wire with serious aging will cause poor contact between the ground wire and the workpiece.

Cutting speed and verticality of torch grip.

The cutting speed should be fast or slow, according to different materials and thicknesses, and the current size should be consistent. Too fast or too slow will cause uneven cutting surface and slag on the upper and lower edges. In addition, the cutting torch is not held vertically, and the sprayed plasma arc is also sprayed obliquely, which will also cause the cutting surface to have a slope.

Troubleshooting

| Problems | Cause of Issue | Solutions |

| Turn on the host "power switch", the power light does not light | 1. "Power Indicator" light is broken | replace |

| 2. 2A Fuse is bad | replace | |

| 3. no input three-phase 380V voltage | Overhaul | |

| 4. input 380V three-phase voltage phase loss. "Lack of phase indicator" light | Use multimeter to measure three-phase voltage should meet the requirements | |

| 5. power and so on | replace | |

| 6. bad control panel or host | Overhaul | |

| After the input three-phase power is turned on, the fan does not turn, but the "Power Indicator" light is on | 1. input three-phase power phase loss | Building materials approach with the table 1.4 |

| 2. the fan leaves stuck by foreign bodies | Remove foreign body | |

| 3. the fan power plug loose | Re-insert | |

| 4. Fan lead off | Overhaul | |

| 5. the fan is damaged | Replace or overhaul | |

| Turn on the three-phase input power, the power indicator light, fan rotation is normal, but open the "test gas" switch, the torch nozzle without air flow | 1. no input compressed air | Maintenance of gas supply and gas pipeline |

| 2. the host back "air filter pressure regulator" imbalance, pressure gauge indicates zero. "Underpressure" indicates red light | Re-adjust the pressure. Method: turn clockwise "air filter pressure reducer" hand wheel to increase, otherwise reduce. | |

| 3. "test gas" bad light | replace | |

| 4. the host electromagnetic valve is bad | Overhaul or replace | |

| 5. gas pipeline leaks or short circuit | Overhaul | |

| Turn on the "test gas" switch, the nozzle has air flow, when the closure of the "cut" light, closed the torch switch, but neither air jet nor the host program action | 1. torch switch broken or broken switch line | Replace or overhaul |

| 2. "cut" switch is bad | replace | |

| 3. the host control circuit board damage | Overhaul | |

| 4. the host control transformer or related lines or components damaged | Overhaul | |

| 5. the host due to lack of pressure over temperature and other reasons in the protection downtime | Until the air pressure returned to normal or the host temperature returned to normal after its return to normal | |

| 6. Water-cooled cutting torch equipped with water cooling system is not working properly, or lack of water in the tank, causing the lack of pressure, so that the host is in a protected state | Check and solve, if the Department of Tap water supply pressure, water pressure should be increased | |

| Turn on the torch switch with air flow in the nozzle but neither "up" nor "up" cut | 1. input three-phase power phase loss | Overhaul |

| 2. air pressure less than 0.45Mpa | Adjust to normal by the method described in Table 3.2 | |

| 3. the input air flow is too small | Increase the input air flow 300L / min | |

| 4. "cut the ground" chuck and workpiece poor conductive or "cut ground wire" wire fracture | Clamp or service conductor again | |

| 5. cutting torch nozzle electrode or other parts damaged | Replacement of new parts | |

| 6. cutting method is not correct | The torch nozzle should be placed on the starting point of the workpiece cutting before turning on the torch switch | |

| 7. cutting torch cable open circuit | Use the multimeter R * 10 file to measure the path between the conductive part of the host "output interface" and the torch electrode, otherwise the surface cable is broken | |

| 8. the host "FD" spark gap too large or short circuit | Re-adjust the tungsten rod gap is about 0.5mm-0.8mm, if the Department of tungsten rod structure, the two gaps add equal to 0.5mm-0.8mm | |

| 9. the host part of the line or component damage, such as pressure controller | Overhaul | |

| 10, the host control board disorders or damage | Overhaul or replace | |

| 11. torch damage | Use a multimeter R * 10K file cutting torch electrode holder and the external thread M32 or M35 resistance value should be close to ∽ to hundreds of K, if the resistance is too small (such as a few K-a few Ω) indicates damage or damp, should After washing and drying measurements, to confirm the damage should be replaced | |

| Contact can be cut, but non-contact can not be cut, the experiment non-transfer arc non-sparking nozzle | 1.15A fuse fuse open circuit | replace |

| 2. "air filter pressure reducer" indicates the value is too high | Adjust according to the method shown in Table 3.2 | |

| 3. Torch electrode nozzle or other parts damaged | replace | |

| 4. cutting torch damp, compressed air moisture content is too large | The torch is dried and the compressed air is dried and then into the machine | |

| 5. "pilot arc interface" to cut the wire between the torch open | Use the multimeter R * 10 file to measure the "pilot arc interface" terminal and the metal torch cutting torch should pass | |

| 6. cutting torch damage | The inspection method is the same as this table 5.11 | |

| Cutting thickness selection switch placed in a file can be cut, but the other file does not work | 1. cut thick switch or wire selection bad | replace |

| 2. one of the host AC contactor CJ1 or CJ2 bad | Replace or repair | |

| 3. rectifier main transformer B1 bad or related wire open circuit | service | |

| Electric arc unstable at work | 1. the pressure is too low or too high | Readjustment, method refer to table 3.2 |

| 2. cutting torch nozzle or electrode burning | replace | |

| 3. input AC voltage is too low | Adjust input AC voltage | |

| 4. "cut the ground" and poor work between the conductive | Connected properly | |

| 5. cutting moving slowly | Adjust the speed of movement | |

| 6. the spark generator can not automatically broken arc | Normal, open the torch switch spark generator discharge time should be 0.5-1S, and then automatically stop, otherwise, that control circuit board disorders; control circuit or component failure, should be overhaul | |

| 7. the relevant components in the host is not working properly | Overhaul | |

| Plasma cutting thickness up to rated indicators | 1. input three-phase voltage up to 380V | Adjust the input voltage |

| 2. the input power capacity is too small cutting pressure drop too much | Should increase the input capacity | |

| 3. enter the compressed air pressure is too low or too high | Adjust to 0.4Mpa, the method see Table 3.2 | |

| 4. enter the compressed air flow is too small, work pressure gauge shows the value dropped from normal to about 0.3Mpa, stop working turn off the power switch, the pressure back to normal immediately | Plus the input compressed air flow to 300L / min; if the system is based on the pipe hole is too small, should be greater than φ8mm bore hole in the pipeline | |

| 5. "cut thickness selection" switch the gear selected inappropriate | Exchange to "upscale" | |

| 6. cutting speed too fast | Slow down the cutting speed | |

| 7. the work material does not match with Table 2 | Adjustment parameters | |

| 8. the nozzle hole has been burned | Adjust the new nozzle | |

| 9. the electrode has been burned | replace | |

| 10. the nozzle model is wrong | Adjust the correct type of nozzle | |

| 11. air system or cutting torch cable damage leakage, then the nozzle orifice flow was significantly reduced | Repair or replace | |

| Cut material bias | 1. the nozzle electrode is damaged | replace |

| 2. the nozzle electrode mounting position is different axis | Re-install correctly | |

| 3. cutting too fast | Appropriate slow down | |

| 4. the nozzle axis and the workpiece plane is not vertical | Adjust and solve | |

| Cutting too wide, poor quality incision | 1. cutting speed is too slow | Adjust the speed |

| 2. the nozzle, the electrode has been burned | Updated | |

| 3. the working material, thickness and "cut thick choice" switch position does not match | Adjustment | |

| 4. the nozzle model is not correct, the hole is too large | Replace the correct type of nozzle | |

| Plasma cutting torch burn out | 1. the metal pressure cap is not compressed | Usually replace the electrode nozzle should be promptly compressed |

| 2. cutting torch conductive joints loose, broken cable trachea, water-cooled torch interface leakage | Check and solve in time | |

| 3. cutting torch joints poor insulation | Should ensure that the insulation at the junction of good | |

| 4. cutting torch ceramic protective cover is damaged, but not promptly replaced | Should be promptly replaced | |

| 5. compressed air in excess water | Timely discharge "air filter pressure reducer" in the water, if the compressed air moisture content | |

| 6. boot cutting, cutting torch model wrong | Parallel cutting should choose water-cooled cutting torch, air-cooled cutting torch carrying capacity is too small, can not be used | |

| 7. the electrode is not replaced after burning | Electrode burn should be promptly updated | |

| 8. water-cooled torch working water system is not normal or the ambient temperature is too low, the interface leakage | Check and solve, and can not work in the freezing temperature environment | |

| Rectifier diodes D1-D6 often burn out | 1. the new diode reverse reverse voltage is too low | Reverse voltage withstand> 1200V diode should be selected |

| 2. C101-C103; C104; C106 or R101; R102 in one or a few damaged | replace | |

| 3. rectifier transformer B1 is damaged | Replace or repair | |

| 4. Plasma cutting torch is damaged | Remove the torch from the main unit, with a multimeter R * 10K file measuring electrode and the torch external thread M32 or M35. the resistance value should be close to ∽, if under tens of K, has been damaged |

Cautions

When using a CNC plasma cutter, the cutting quality is unstable, and the wearing parts are replaced frequently. It is found that the user's operation is not standardized enough during operation, and at the same time, he does not pay enough attention to some details. Summarized some tips for the daily use of CNC plasma cutting machines, hoping to bring you convenience:

The cutting should start from the edge.

When possible, start cutting from the edge, rather than perforating the cut. Using the edge as a starting point will prolong the life of the consumable, the correct way is to aim the nozzle directly at the edge of the workpiece before starting the plasma arc.

Reduce unnecessary "arcing (or piloting)" time.

Both the nozzle and electrode are consumed very quickly when starting the arc, and the torch should be placed within walking distance of the cutting metal before starting.

Do not overload the nozzle.

Overloading the nozzle (that is, exceeding the operating current of the nozzle) will cause the nozzle to fail quickly. The current intensity should be 95% of the working current of the nozzle. For example: the amperage of a 100A nozzle should be set to 95A.

Use a reasonable cutting distance.

According to the requirements of the instruction manual, a reasonable cutting distance is adopted. The cutting distance is the distance between the cutting nozzle and the surface of the workpiece. When perforating, try to use a distance twice the normal cutting distance or the maximum height that can be transmitted by the plasma arc.

The thickness of perforation should be within the allowable range of the machine system.

The cutting machine cannot pierce the steel plate that exceeds the working thickness. The usual piercing thickness is 1/2 of the normal cutting thickness. Try to keep the torch and consumables clean. Any dirt on the torch and consumables will greatly affect the plasma function of the system. When replacing consumables, put them on a clean flannel, check the connection rib of the torch frequently, and clean the electrode contact surface and nozzle with a hydrogen peroxide-based cleaner.