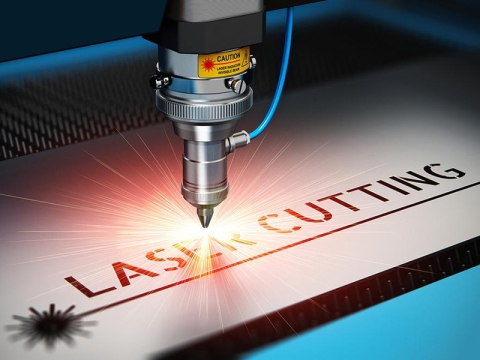

In modern days, laser cutters walk through everywhere in our lives and businesses, from small home stores to large industrial manufacturers, handling a variety of materials from soft fabrics to hard metals, and creating everything from simple lettering to complex 3D puzzles. Powerful yet easy to use for both beginners and professionals alike. Have you factored that into your business plan? Is this a cutting tool worth the money? Let's first explore the pros and cons of laser cutters.

Here's a balanced overview of laser cutter pros and cons, covering key factors for hobbyists, makers, and professionals:

✅️ Pros (Advantages & Benefits)

Precision Cutting & Fine Engraving

Lasers are professional to create fine cuts and intricate engravings that are beyond the reach of most manual and mechanical cutting tools, making them ideal for complex designs, fine text, and detailed artwork.

Material Diversity

Lasers can engrave and cut a wide range of materials: wood (plywood, MDF, solid wood), acrylic (plexiglass), leather, fabric, paper, cardboard, rubber, stone, glass, stainless steel, carbon steel, copper, aluminum, alloys, and some composites. (CO2 lasers are best for nonmetal materials; fiber lasers are ideal for metal materials).

Clean Cuts & Edges

Lasers can create smooth edges in a variety of materials by setting power options, material properties, and cutting parameters, eliminating the need for post-processing steps such as polishing and grinding, saving time, effort, and material waste.

High Speed & Efficiency

Compared with manual cutting tools or CNC cutting machines, laser cutters are faster at cutting and engraving, making them popular for rapid prototyping and mass production.

Repeatability & Consistency

Once your design and setup are complete, each subsequent cut is exactly the same, making them ideal for batch manufacturing.

Non-Contact Process

The laser beam cuts without physical contact with the material, which is safe and reduces the possibility of material displacement or damage during the cutting process.

Automation and Software Integration

Laser cutting machines can work with most CAD/CAM software (such as Adobe Illustrator, CorelDRAW, AutoCAD, LightBurn), which makes it easy to create, modify and send designs to the controller.

Minimum Waste (Kerf)

The laser beam is very thin ("kerf"), which means less material waste than thicker cutting tools such as saw blades, especially in nested designs.

Flexibility

Easily switch between cutting and engraving on the same machine with a simple software change.

❎️ Cons (Disadvantages & Limitations)

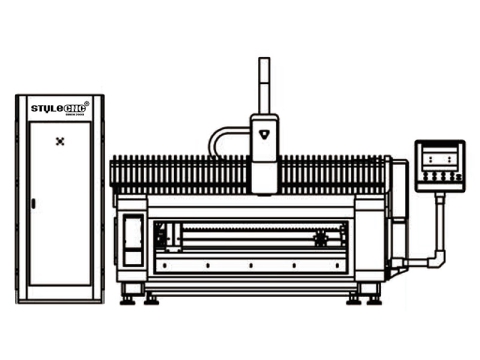

High initial cost

A reliable CO2 laser cutter (even a desktop cutter) is expensive to purchase, and even more so, industrial-grade fiber laser cutting machines can cost tens of thousands of dollars, requiring a huge investment.

Material restrictions

CO2 lasers are typically used for cutting non-metallic and metalloid materials, and perform poorly in metal cutting other than thin sheet metal. Fiber lasers are only allowed to cut metal.

Hazardous materials

PVC, PTFE, vinyl, polycarbonate, Teflon, and materials containing chlorine or bromine produce toxic fumes that are harmful to health. Never cut unknown plastics and foams.

Highly reflective metals

Aluminum, brass, and copper can reflect the laser beam and damage the laser generator (special fiber lasers are required to cut reflective metals).

Thickness restrictions

The power determines the laser cutting capability. Thick materials require high-power lasers.

Safety Hazards

Extreme fire risks

Laser cutting generates high heat, which makes it easy for unattended operation or improper settings to ignite the material being cut (especially fabrics, paper, and wood), requiring fire extinguishers and safe operating procedures.

Toxic Fumes

Laser engraving or cutting certain materials can produce toxic and hazardous fumes, requiring specialized exhaust fans and ventilation systems to ensure safe production.

Personal Injury

Eyes may suffer laser damage and skin may suffer laser burns if exposed to lasers of certain wavelengths and intensities, requiring appropriate shielding and laser safety glasses.

Operating Costs and Maintenance

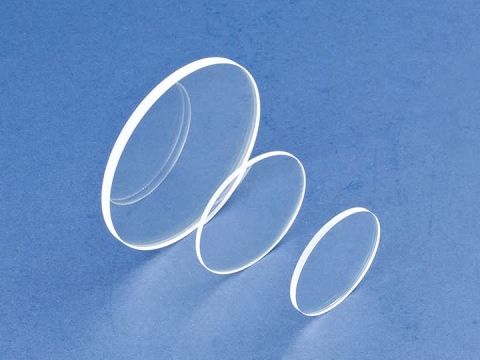

Consumables such as CO2 laser tube, mirrors and lenses, nozzle, protective lens, ceramic ring, and auxiliary gas come with a limited lifespan and high replacement costs, and require regular cleaning, calibration, care and maintenance.

Learning Curve

A deep learning curve is required in terms of operation, maintenance, safety procedures, and mastering CAD design software and cutting parameter settings (power, frequency, speed, focal length).

Edge Characteristics

Taper

Laser cutting will produce a slight taper (wider top and narrower bottom), which is particularly noticeable on thick materials.

Scorching/Blackening

The edges of laser cut solid wood, plywood, MDF, and bamboo will be charred and darkened.

Heat Affected Zone (HAZ)

The area near the laser cut edge may discolor or deform due to heat, especially on plastics and some sensitive materials.

Optimal Settings

Extensive testing is required to find the optimal settings (power, speed, frequency, focus, air assist) for each specific material type and thickness.

Noise and Space

Laser cutting generates noise (air compressor, exhaust fan, laser operation), and large-size industrial laser machines take up a lot of space, requiring a reasonable layout of the workshop.

In Summary

Laser cutters are smart manufacturing tools for precision cutting and engraving of various metal and non-metal materials, with features such as fast speed, high accuracy, high repeatability and flexibility. However, they require a high initial investment (equipment and site), carry serious safety responsibilities (personal injury and fire), and require continuous learning and practice. If your business requires you to purchase your own laser cutter, weigh the pros and cons based on your specific business needs and budget, as well as your workspace and safety commitments, and make a decision. For occasional laser cutter users, using a local laser cutting service may be more appropriate.

Whether a laser cutter is worth the money depends entirely on your specific business needs and budget, as well as your frequency of use and goals. The following categories will help you decide:

✔️ When is it worth buying a laser cutting machine?

High-volume production or commercial use

If you run a business (e.g., Etsy shop, auto parts, sheet metal fabrication, custom signage, prototyping, crafts, jewelry, art, and gifts) that requires consistent, precise cutting and engraving, a laser cutter can quickly pay for itself with its efficiency and scalability.

Hobbyist or Maker Wwho Laser Cuts Frequently

If you spend a lot of time and money outsourcing your laser cutting, or have complex projects that are difficult to complete with hand or machine tools (knife, saw), owning a laser cutter can save time and unleash your creativity.

Experiment with a variety of materials (e.g., wood, acrylic, leather, fabric, paper, and some metals with fiber lasers) and complex designs that are impossible to accomplish by hand.

Specific Material Needs

Essential for cleanly cutting/engraving acrylic, fine wood inlays, detailed leatherwork, or metal marking (with the right laser).

Space and Performance Match

You have ample, well-ventilated space (critical!), power needs, and a budget for the machine and basic accessories (extractor, compressor, air assist, cooling).

Technical Ability and Interest

You are comfortable learning the software (CAD, Illustrator, LightBurn) and performing basic maintenance (calibrating mirrors, cleaning lenses, troubleshooting).

✖️ When is a laser cutting machine not worth owning?

Infrequent or Occasional Use

If you need laser cutting or engraving occasionally, but not often, outsourcing your business may be more cost-effective, saving you a series of tedious operations such as learning, purchasing, operation, and maintenance.

Tight Budget (with Hidden Costs)

Machine Cost: Laser cutters range from around $1,000 (entry-level models) to $6,000 (professional models) to $10,000+ (industrial models).

Must-Have Extras: High quality fume extraction ($200 to over $1,000), air assist (approx. $100 to $300), cooling system (CO2 water chiller - $150 to $500), replacement lenses/mirrors, honeycomb bed, and materials, all of which can easily double the initial cost of the machine.

Maintenance and Repairs: During the use of the machine, there should be regular constant care and maintenance, which should be considered in terms of ongoing costs.

Space and Ventilation Limitations

Lasers require a lot of space and must have proper ventilation (legal and safety aspects).

Material Limitations/Alternatives

Need to cut thick metal? A plasma cutter or water jet cutter is a more affordable option.

Need to cut thin paper, card stock, vinyl? Cricut and Silhouette are cheaper, quieter, and safer.

Need simple wood cutting? A good jigsaw or bandsaw will suffice.

Intolerable Hassle

Requires setup, calibration, maintenance, material testing, and troubleshooting. Not truly "plug and play" (except for the Glowforge, but that's more expensive).

Security Risks

Fire Risk: Never leave a laser unattended. Constant vigilance is required.

Toxic Fumes: Cutting certain materials (PVC, vinyl, certain treated woods) can release deadly fumes. Proper extraction is a must.

Eye Damage: Strict eye protection is a must (preferably an enclosure with an interlock).

☑️ Key Considerations Before Buying

Budget: Actual total budget (machine + all accessories + materials + maintenance buffer).

Primary Use Cases: What materials are cut? What thickness? Cutting, engraving, or both? Production volume?

Space & Ventilation: Do you have a dedicated, well-ventilated workshop/garage? Can you install ducting?

Technical Skills: Are you good at debugging and troubleshooting software and hardware?

Time Commitment: Will you use these resources well enough to offset the cost/hassle?

Alternatives: Have you tried other cutting tools? Would a CNC router or vinyl cutter suffice?

☑️ Recommendations

Calculate Outsourcing Costs: Estimate how much it would cost you to outsource your laser cutting work each year. How long would it take for a machine to pay for itself?

Try Before You Buy: Experience a laser cutter at a local dealer, makerspace, or friend’s studio before committing to a purchase.

Start Small: If you're a hobbyist, a powerful CO2 laser can be a low-risk starter option (about $1,200 to $3,600), but be aware of their limitations (slower, thinner, and primarily cuts non-metallic materials).

Research Relentlessly: Check online reviews (Amazon and Google), join forums (Reddit: r/lasercutting), compare specs, and learn about software.

☑️ Bottom Line

If you use it often enough to justify the high upfront investment and ongoing costs, and it unlocks features that are critical to your projects or business, then a laser cutter is definitely worth the money. If not, outsourcing or another tool is a smarter choice.