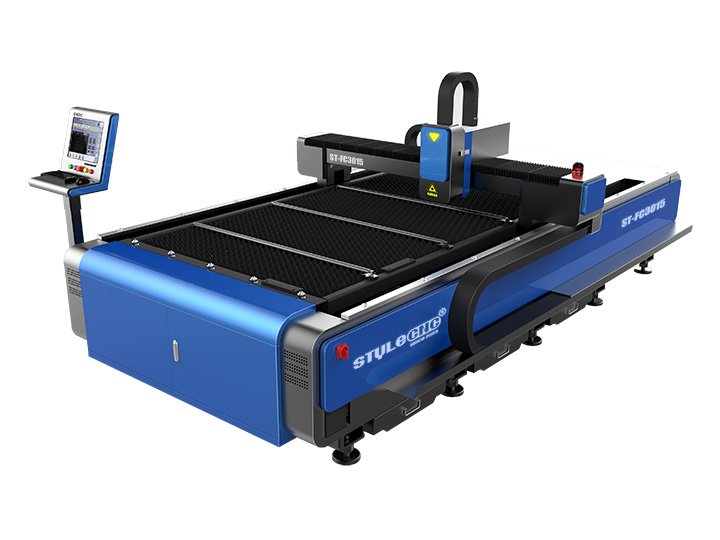

| Laser generator | Model | Single-mode, multimode, low mode are suitable for thin plate cutting, high-modulus is suitable for thick plate cutting |

| Power | The cutting performance is decided by the laser power | |

| Light path | Collimating mirror | The larger collimation, the smaller focusing spot,the higher focused energy, the shorter focal dept,is not suitable for cutting thick plate,usually use F=75mm,F=100mm |

| Focusing lens | the smaller focusing lens, the larger focusing spot,short of focal depth,is suitable for cutting thin plate,usually use F=150mm,F=200mm | |

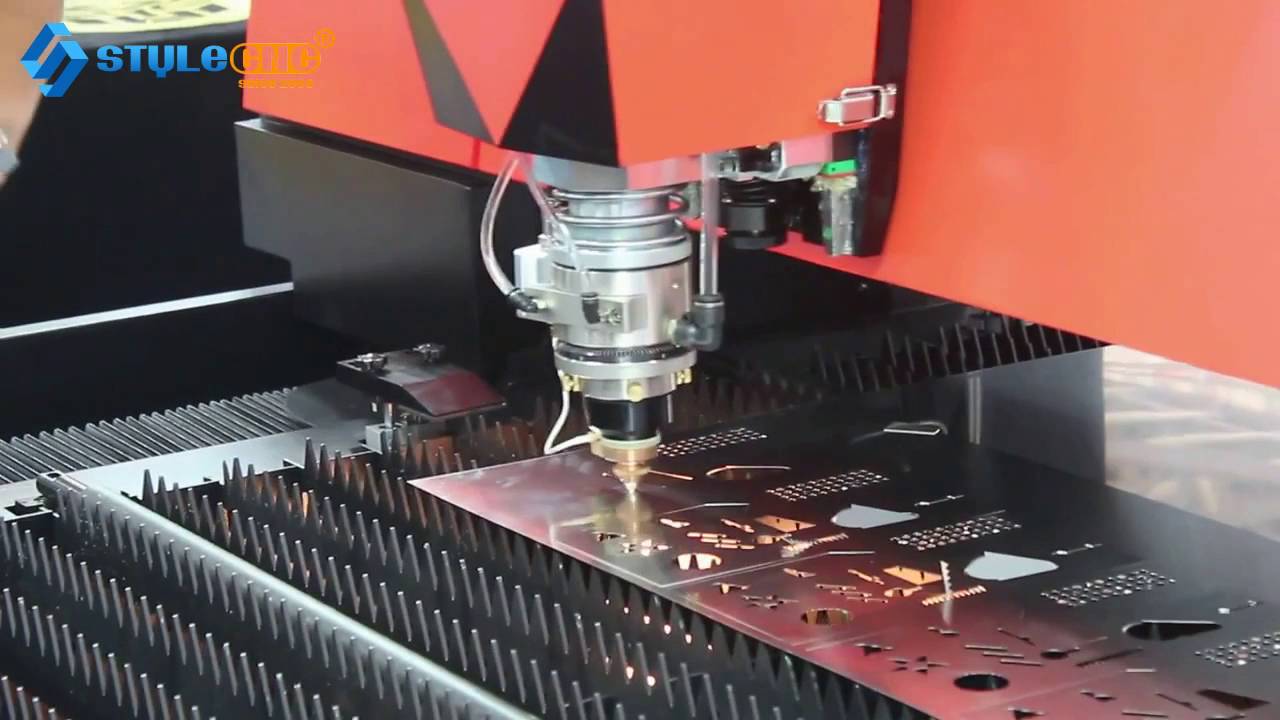

| Air cock | Gas mouth shape | Effect the speed of the cutting point airflow |

| Gas mouth size | 1.0-2.0mm different thickness of plate,choose different size of gas mouth | |

| Gas mouth height | Effect airflow, then effect the final cutting result | |

| Auxiliary gas | Dry,oily degrees | Effect on laser energy |

| Gas purity | Oxygen purity 2% lower,cutting speed lower50% | |

| Gas flow | Size of flow,effect the cutting speed and effect on the back | |

| Gas pressure | The pressure, effect cutting speed meter edge effectivness | |

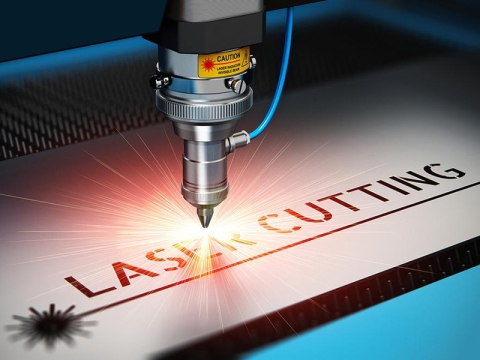

| Cutting parameters | Cutting speed | The speed, pressure, laser power, all effect the cutting results |

| Height of focus | Depth of focus determines the work positionof focus on different thickness of the plate | |

| Cutting materials | Thickness of plate | 0.1-12mm thickness plate,affect the efficiency and effectiveness |

| Melting point of material | melting point,affect the cutting effectiveness | |

| Material absorptivity of laser | The material absorptance of laser ( 1.64um ) |