Fiber Laser Cutter Daily Maintenance Criterion

1. Before starting up the fiber laser cutting machine, first check the 2nd and 3rd reflecting mirror, as well as check whether there is any dust on the mirror or any broken in the mirror.

2. Before cutting, please make sure the belows:

A. Check the pressure of air compressor to make sure its no less than 0.8Mpa, and try to open the protection air and up-down gun to check whether is smooth.

B. First up the cutting head, then run aside the edge frame, make sure the cutting pieces within the range of the setting area.

C. Simulate the processing output, make sure the cutting order whether is reasonable.

D. Adjust the height of cutting head to the suitable drilling place.

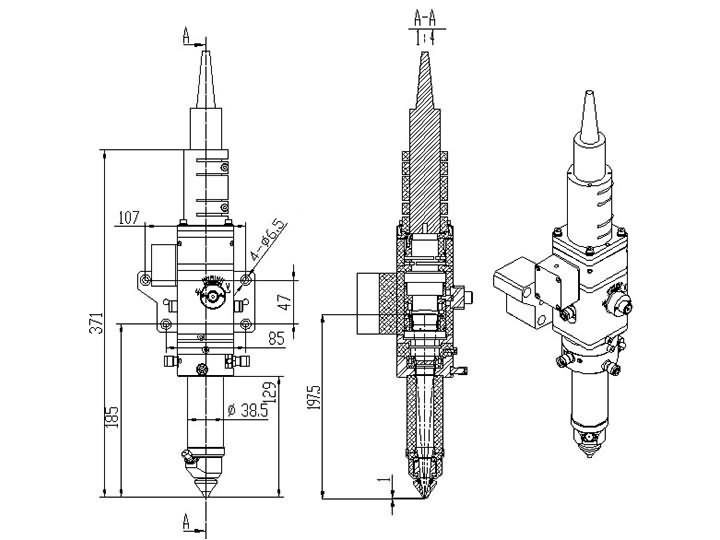

3. When cutting, observe whether is cutting out at any moment, if not, first up the cutting head by hand then stop cutting, and check the cutting parameter whether is right, and the spray nozzle and protecting mirror whether is damage, adjust well, then return back to un-cutting, then continue to cut.

4. When cutting, observe the cutting piece whether is turning over or up. If so, take over it in case of the collision between cutting head and piece, if the sheets is not plain, adjust its to the suitable drilling height (3-5mm) at any moment.

5. When cutting, observe the cutting head whether is fire up, if so, stop cutting, and check the spray nozzle about the abrasion, judge the focus whether is changing, if so, increase or reduce the pad depended the situation.

6. Every month clean the water-cooling machine one or two times, change the cycled water inside its, and use the distilled water without any impurity, can not use the tap water. purified water or mineral water.

7. Must make sure the close down of light out signal and protecting gas so that it can change the spray nozzle. protecting mirror and focus mirror and so on.

8. Clean off the metal dregs in the suctiondraft slagcatcher.

9. After the laser power supply electrified, at any time can not have a direct eye to the light out hole and any place the laser may be reflecting.

Maintenance Schedule for Fiber Laser Cutting Machine

| No. | Check Cycle | Check Place | Check Requirement |

| 1 | Everyday | Working table | Clean it |

| 2 | Everyday | X axis leather tiger | Keep its move smoothly |

| 3 | Everyday | Connect wire | Check each wire whether is tense and broken |

| 4 | Everyday | Control box | Check the fan of control box whether is normal |

| 5 | Every week | X axis screw | Open the leather tiger and clean screw, then add oil |

| 6 | Every week | Y axis screw | Clean screw, then add oil |

| 7 | Occasionally | Check computer | AntiVirus. Disk tidy |

| 8 | Occasionally | Screw nut | Check the fixing screw of screw nut whether is damaging |

| 9 | Every day & week | Protecting mirror. | Check mirror and clean it |

| 10 | Occasionally | Water path. wind path | Check the joint of water pipe and wind pipe whethe is damaging and blocking |

In order to enhance the using life and cutting precision of the fiber laser cutting machine, please operate as above. Use the original qualified Consumable, if not, it will cause the serious fault.