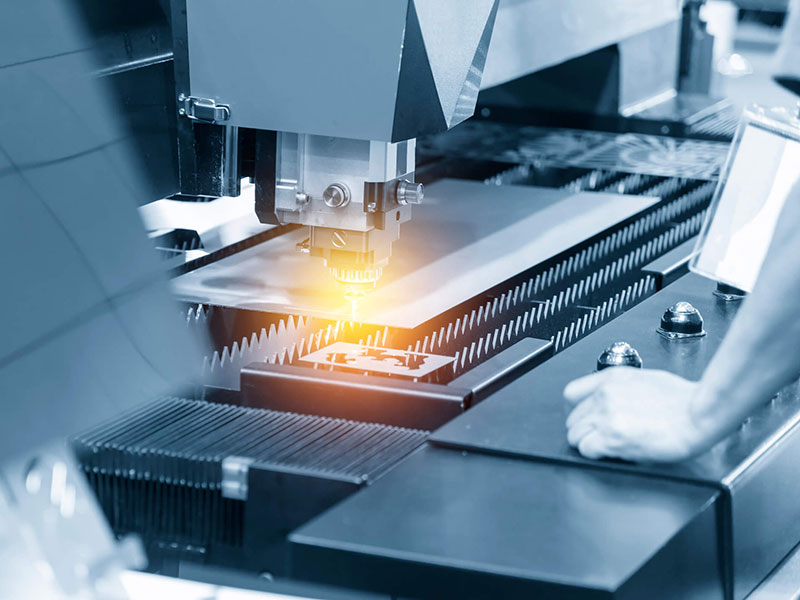

Fiber laser cutting machine is a new laser type, it output high energy density laser beam, then gathered on the surface of the workpiece, workpiece instantaneous melting and evaporation via ultrafine focus facula illumination, the CNC system moving the laser beam irradiation position and automatic cutting. Compared to solid state lasers, fiber laser cutting machine has obvious advantages, has gradually developed into a important candidates in the field of high precision laser processing, laser radar system, space technology, laser medicine and so on.

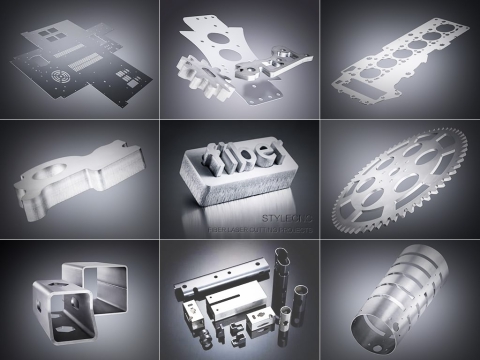

Fiber laser cutting machine which can do the flat cutting also do the angle cutting and edge neatly, smoothing on the metal plate, such as high precision cutting, and mechanical arm can be three-dimensional cutting instead of original imported 5-axis laser. Compared with ordinary CO2 laser cutting machine, fiber laser cutting machine saves more space and gas consumption, high photoelectric conversion rate, is a new energy saving and environmental protection products, is also one of the world's leading technology products.

Advantages and Benefits of Fiber Laser Cutting Machine:

1. Fiber laser electrical to optical conversion efficiency is high, conversion efficiency of more than 30%,greatly reduce the power consumption, save operation cost, achieve the highest production efficiency;

2. The operation of the laser only requires power, no need to generate additional gas laser, with the lowest operating and maintenance costs;

3. Fiber laser by semiconductor module and the redundancy design, resonant cavity free optical lens, does not require bootstrap time, with adjustment free, maintenance free, the advantages of high stability, reduce the cost of spare parts and maintenance time, which is unmatched by traditional laser;

4. Fiber laser output wavelength of 1.064 microns is 1 / 10 of the CO2 wavelength, the output beam quality, high power density, is very conducive to the absorption of the metal material, has excellent cutting and welding ability, so that the least cost of processing;

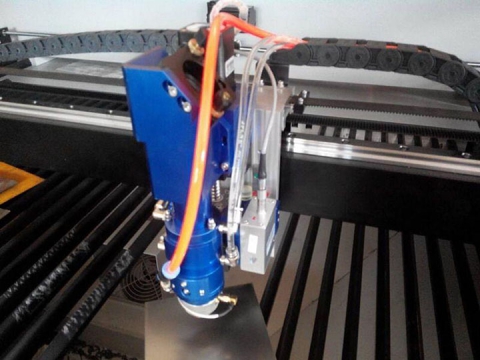

5. The whole routing optical fiber transmission, does not need the complex mirror and so on the light guiding system, the light path is simple, the structure is stable, the outside light road maintenance free;

6. The cutting head contains a protective lens, the focusing mirror and other precious consumable few consumption;

7. The light through the optical fiber are derived, the design of mechanical system is very simple and very easy to work with the robot or multidimensional integration;

8. After a gate coupled with laser multi machine, light through the optical fiber, divided into multi Taiwan work at the same time, the function is easy to expand, upgrade convenient and simple;

9. Fiber laser has the advantages of small size, light weight, position mobile, small area.