Laser Cleaner for Historic Stone & Artifact Restoration

Need a laser cleaning system for historic stone and artifact restoration? Review the laser cleaner for removing soil, dirt, carbon deposits, rust, oxide layers.

Looking for a portable laser cleaning machine for paint stripping or coating removal from aluminum, steel, brass, copper, and more metals? Review the 100W laser paint stripping machine and laser coating removal machine to learn more.

Are you searching a portable laser cleaning solution to effectively strip paint or remove coatings from a range of metals including aluminum, steel, brass, and copper? This is the right place. The review of the 100W laser paint stripping and coating removal machines will add some comprehensive insights.

There are two key ways for paint stripping and coating removal from traditional industrial products:

The first method for paint stripping or coating removal involves chemical processes. This entails using a paint agent to swell and dissolve the paint layer on the product. Common agents include alkaline or organic paint removers. Traditional paint removers typically utilize solvents like methylene chlorides, alcohols, esters, and benzene derivatives such as trioxymethane. However, these solvents are highly volatile, toxic, and contribute to significant environmental pollution, posing risks to operators. Inhalation or skin contact with benzene in significant amounts can lead to acute and chronic benzene poisoning. Exposure to very high concentrations may even result in loss of consciousness and fatalities among workers.

And the second one involves physical techniques. This entails employing mechanically powerful methods to eliminate the paint layer from the product. Examples include manual scraping or high-pressure water flushing to remove the paint. Manual scraping involves using tools like knives, sandpaper for sanding, or washing with water, which are simple yet effective methods for this purpose.

Though both methods mentioned above are commonly used, they have certain and with significant drawbacks. Chemical paint removal relies on chemical reagents, resulting in environmental pollution, inefficiency, and potential substrate damage. Additionally, these volatile chemicals pose health risks. Physical paint removal, on the other hand, can easily damage substrates and electrical products, leading to leakage or short circuits. Moreover, it is noisy, labor-intensive, and often yields unsatisfactory results.

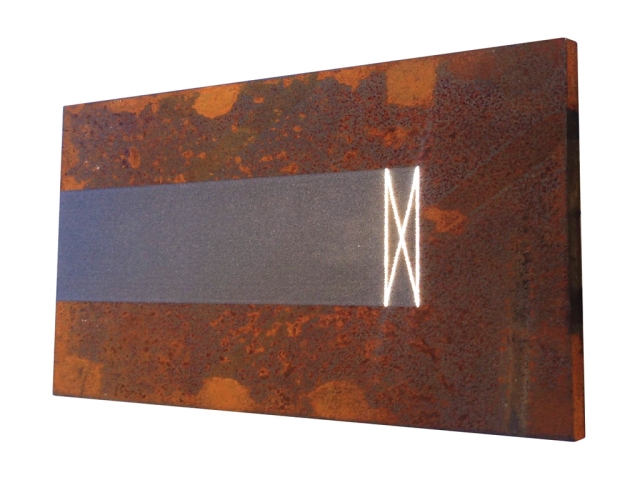

In testing, it was found when the expansion force generated by the oil method exceeds the adhesive force holding the paint to the substrate, the paint separates from the object's surface. Laser cleaning machines apply laser brightness and employ mechanisms like thermal vibration, thermal shock, and sonic vibration to deliver laser shots onto the object's surface. It breaks the adhesion between the paint and the substrate without posing any damage or threat to the substrate itself. Through methods like photochemical decomposition and laser ablation, the oxide or paint layer on the object's surface is removed, achieving the desired outcome of paint removal.

Laser paint removal technology can be said to be the life of paint removal technology in industrial products. It has an advantage that traditional physical paint removal technology cannot match.

• No chemical solution is needed, so there is no environmental pollution problem caused by chemical solution.

• The removed waste is basically solid powder, small in size, and basically does not cause pollution to the environment.

• Laser coating removal is non-contact type, which is transmitted through optical fiber and combined with robots or manipulators to facilitate remote operation.

• Laser paint stripping machine can remove different types and thicknesses of paint on the surface of various materials to achieve a high degree of cleanliness.

• Laser paint removal can selectively remove dirt on the surface of the material without damaging the internal composition and structure of the material.

• The parts that need paint removal can be at any temperature, and can not be affected by the shape of the product, and can effectively remove the positions on the product surface that cannot be reached by traditional paint removal methods.

• Laser coating removal machine is easy to move, can be used stably for a long time, and can easily realize automatic operation.

• The working efficiency of laser paint stripping is high.

Laser paint stripping and coating removal technology is highly efficient and environmentally friendly. It's pollution-free, noise-free, and poses no harm to humans or the environment. So, you can rely on it without a second thought.

Need a laser cleaning system for historic stone and artifact restoration? Review the laser cleaner for removing soil, dirt, carbon deposits, rust, oxide layers.

Need 1000W laser rust removal machine for non-destructive rust removal from metal without damaging? Review the laser removed rust projects & applications.

Looking for 200W laser cleaning machine for tire mold, rubber mold, shoe mold, injection mold, glass mold? Review the laser mold cleaning machine projects.