Mechanical and electronic products require cleaning maintenance before assembly and after a period of operation, including cleaning some materials or components. Traditional mechanical friction cleaning, chemical corrosion cleaning, strong impact cleaning, and high-frequency ultrasonic cleaning are time-consuming without automation and usually have harmful effects on the environment. At the same time, there is no reliable way to measure the cleaning effect. In contrast, laser cleaning has the advantages of no pollution, no consumables, low cost, high efficiency, no contact, no stress, no damage, good controllability, precision cleaning of optional areas, and the ability to clean dangerous areas. It is considered to be the most reliable and effective solution to cleaning problems in the future.

What is a Laser Cleaning Machine?

A laser cleaning machine is a device that uses laser beam technology to remove coatings, rust, and contaminants from the surface of a material.

The laser cleaner is an environmentally friendly cleaning tool that uses nanosecond or picosecond pulsed lasers to irradiate the surface of the workpiece to be cleaned so that the surface of the workpiece instantly absorbs the focused laser energy to form a rapidly expanding plasma (highly ionized Unstable gas) to make the surface oil, rust, dust, coating, oxide layer or film vaporized or peeled off, to efficiently remove surface attachments.

Laser cleaners come with two different types of laser source,

1. Fiber Lasers and

2. Solid-State Lasers

How Does A Laser Cleaning Machine Work?

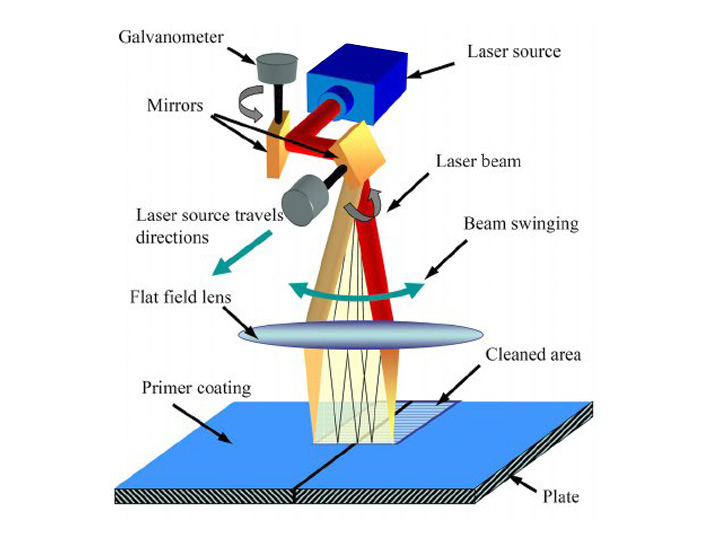

• The laser cleaning machine is generally composed of a laser, a beam transmission shaping unit, an automatic control operating system, a cleaning quality detection and protection unit, and a displacement platform.

• At first, the laser beam interacts with the contaminants on the surface. The energy vaporizes the contaminants and removes them.

• This process is highly selective with the type of removal materials. It can specifically remove rust or coatings without damaging other layers. Since this is a non-contact cleaning method it is more popular now comparing traditional cleaning methods.

Key Components of A Laser Cleaner

Laser cleaning is fun when you know how to use the machine properly. To do that knowing all the parts and their usability is crucial. Let’s take a look at the parts and their importance.

Laser Generator: The generator is the main source of the laser beam.

Optical System: The optical system focuses and directs the laser beam onto the surface.

Control System: The control system manages the laser parameters like power, pulse duration, and frequency.

Cooling System: To prevent overheating of the laser machine cooling system is a must.

Laser Cleaning Machine Features & Advantages

At present, the cleaning methods widely used in the cleaning industry include mechanical cleaning, chemical cleaning, and ultrasonic cleaning, but their application is greatly restricted under the constraints of environmental protection and the requirements of the high-precision market. The laser cleaning machine has obvious advantages in various industries.

✔ Automated assembly line: The laser cleaning machine can be integrated with CNC machine tools or robots to implement remote control and cleaning, which can realize the automation of the equipment, and form a product assembly line operation and intelligent operation.

✔ Accurate positioning: Use optical fiber to transmit and guide the laser to make it flexible, and use the built-in scanning galvanometer to control the high-speed movement of the light spot, which is convenient for non-contacting of special-shaped parts, holes, grooves, and other parts that are difficult to reach by traditional cleaning methods. Ground laser cleaning treatment.

✔ No damage: Short-term impact will not heat the metal surface and cause no damage to the substrate.

✔ Good stability: The pulse laser used in the laser cleaning machine has a long service life, usually up to 100,000 hours, with stable quality and good reliability.

✔ No environmental pollution: no chemical cleaning agent is needed and no cleaning waste liquid is generated. The pollutant particles and gas generated during the laser cleaning process can be collected and purified by the portable exhaust fan to avoid environmental pollution.

✔ Low maintenance cost: There is no consumption of consumables during the use of the laser cleaning machine, and the operating cost is low. In the later stage, only the lens needs to be cleaned or replaced regularly. The maintenance cost is low, and it is close to maintenance-free.

Laser Cleaning Machine Applications

Applicable Materials

In the field of industrial applications, laser cleaning objects are divided into two parts: the substrate and the cleaning object. The substrate mainly includes the surface contamination layer of various metals, semiconductor wafers, ceramics, magnetic materials, plastics, and optical components. The cleaning objects mainly include facing In the industrial field, rust removal, paint removal, oil removal, film/oxidation removal, and resin, glue, dust, and slag removal are widely used.

Applicable Industries

The research of laser cleaning technology started in the mid-1980s, but it did not really enter industrial production until the early 1990s. It has achieved good results in mold cleaning, material surface treatment, large-scale equipment and precision machinery, etc. application. In addition, European countries generally retain a large number of historical relics and ancient buildings. Many churches, castles, universities, museums, sculptures, etc. have hundreds or even thousands of years of history. Europeans have paid great attention to the protection and restoration of these "antiques". Laser cleaning technology has been used for the restoration and decontamination of cultural relics.

Microelectronics Field

Semiconductor components, microelectronic devices, memory templates, silicon templates, etc. to remove particles and component pins to remove oxides.

Cultural Relic Protection

Stone carvings, bronzes, glass, paper, oil paintings, sheepskin scrolls and murals, etc.

Mold Cleaning

Rubber molds, composite molds, metal molds, etc.

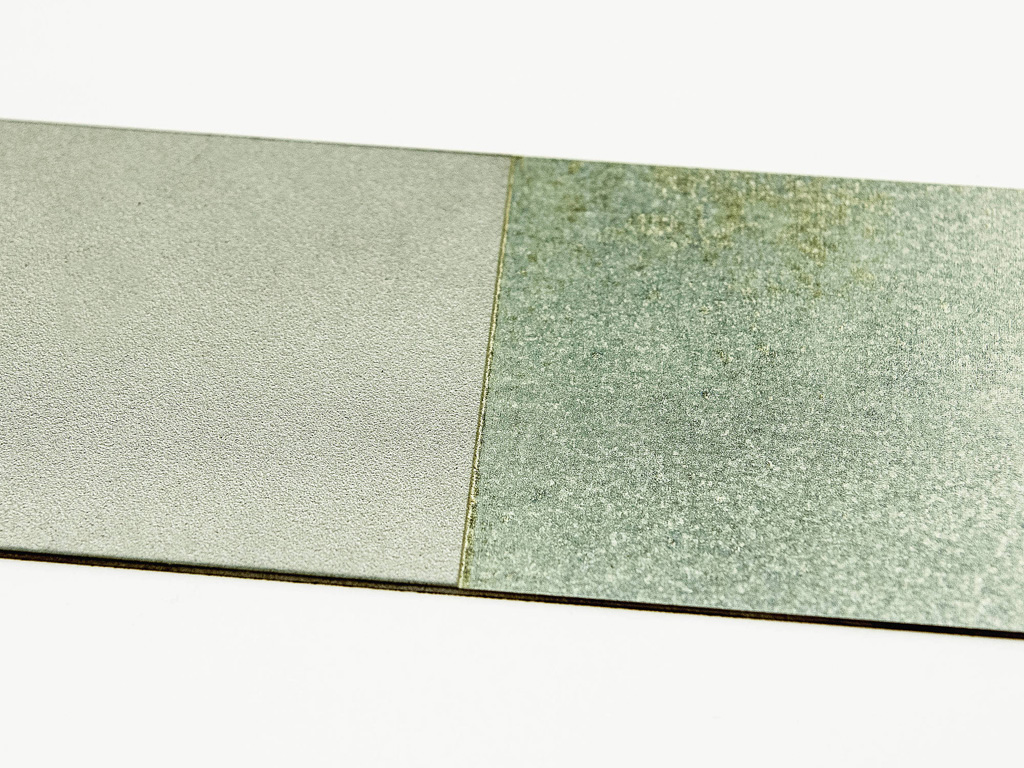

Surface Treatment

Hydrophilic treatment, surface roughening, pre-treatment before welding.

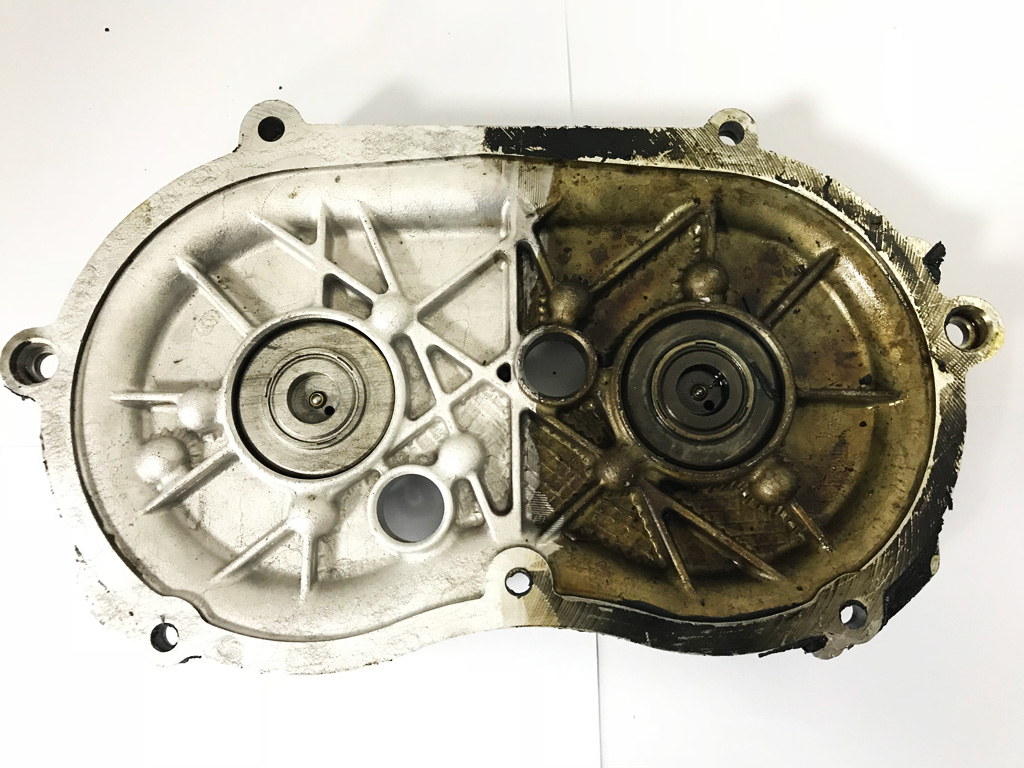

Paint Stripping & Rust Removal

Fully automated laser paint and rust removal systems for aircraft, ships, weaponry, bridges, iron towers, etc.

Precise paint removal of precision parts: aircraft parts, electrical products (instead of etching), etc.

Others

Urban graffiti, printing rollers, degreasing of industrial parts of precision machinery, cleaning of building exterior walls, nuclear pipelines, and other dangerous industries.

Others

Urban graffiti, printing rollers, degreasing of industrial parts of precision machinery, cleaning of building exterior walls, nuclear pipelines and other dangerous industries.

Operating a laser cleaning machine

Operating a laser cleaning machine is easy once you learn the instructions and follow them accordingly. We have included the basics of operating a laser cleaning machine here. But we suggest reading the manual thoroughly before operating the machine.

Initial Setup:

✔ Read the manual and familiarize yourself with the machine’s manual and safety instructions.

✔ Set up the work area. Ensure the work area is clean and free of flammable materials.

✔ Connect the machine to a power source and turn it on.

✔ Adjust settings accurately and set the laser parameters according to the material and contaminant.

Cleaning Process:

✔ Focus the laser and adjust the length to ensure the laser beam is precisely focused on the surface.

✔ Perform a test run on a small, inconspicuous area to ensure optimal settings.

✔ Proceed with cleaning. Move the laser head methodically over the surface, maintaining a consistent speed and distance.

✔ Continuously monitor the cleaning process to avoid overheating or damaging the substrate.

Maintenance and Troubleshooting!

Regular Maintenance:

• Clean the Optics: Keep the laser lens and mirrors clean.

• Check Connections: Ensure all electrical and cooling connections are secure.

• Software Updates: Keep the control software updated.

Common Issues:

• Inconsistent Cleaning: Check for proper focusing and adjust settings.

• Overheating: Ensure the cooling system is functioning correctly.

• Power Fluctuations: Verify stable power supply and check for any loose connections.

Laser Cleaning Projects & Plans

Typical applications of laser cleaning include mold cleaning, industrial rust removal, old paint, and film removal, pre-welding and post-welding treatment, de-esterification of precision parts, decontamination and deoxidation of electronic components, and cultural relics cleaning. Laser cleaning machines are widely used in metallurgy, molds, automobiles, hardware tools, transportation, construction home appliances, machinery, and other industries.

Laser Rust Removal Project

Laser Oil Dirt Cleaning Project

Laser Paint Stripping Project

Laser Coating Removal Project

Laser Rubber Tire Mold Cleaning Project

Laser Stone Statue Cleaning Project (Cultural Relic Restoration)

How Much Does A Laser Cleaning Machine Cost?

The price of laser cleaning is based on your specific application requirements, with corresponding equipment. In the equipment configuration, the higher the laser power, the higher the price. It depends on the power of the laser, and the power selection of the laser needs to be determined according to the needs, such as the cleaning speed requirements, the thickness of the cleaning material, the material itself, and other factors.

Portable Handheld Laser Cleaning Machine for Sale

The price of a 1000W laser cleaning machine starts from $10,800, and the price of a 1500W laser cleaning machine is priced from $13,000 to $14,500. The cost of 2000W laser cleaners starts from $19,800, and the highest price is $28,500.

The automated laser cleaning robot workstation adopts a non-standardized design, which can adapt to different places and meet the cleaning needs of different industries and different working conditions. Its price starts from $62,800.