Surface cleaning has improved significantly with the advancement of technology. Nowadays, traditional cleaning methods are too slow to compete with the challenge. Technology offers several surface cleaning tools and tech in the cleaning industry. Laser cleaning, sandblasting, and dry ice blasting are the most popular ones.

These three different methods use different technologies and materials to do the cleaning and are sometimes object-specific. Today we will discuss the laser cleaning, sandblasting, and dry ice blasting cleaning methods and compare them. We will also provide the differences more specifically so that you can choose the proper method to do your cleaning job. But first, take a look at what these cleaning technologies are all about.

• Laser Cleaning

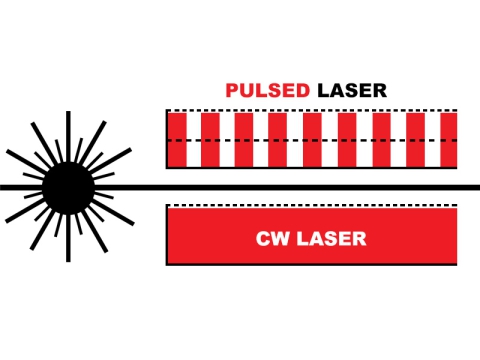

Laser cleaning vaporizes contaminants and coatings using a heated and concentrated laser beam. In this process, the laser beam directly hits the contaminated surface and causes the contaminants to absorb the energy and evaporate or sublimate.

• Sandblasting

Sandblasting utilizes abrasive materials such as sand to clean contaminants from the surface. It uses sand propelled at a high velocity against a surface to remove coatings and contaminants. The abrasive particles scrape off the contaminants creating friction.

• Dry Ice Blasting

Dry ice is solid carbon dioxide. This method uses dry ice to shoot the pellets at high speed on the surface of the material. Due to thermal shock and mechanical impact the dry ice sublimates any contaminants upon impact.

Operational Differences

Laser cleaning, sandblasting, and dry ice blasting feature different operational methods and techniques.

| Laser Cleaning | Sandblasting | Dry Ice Blasting |

|---|---|---|

| Utilizes highly focused laser beams, typically in the ultraviolet, infrared, or visible spectrum | Sandblasting involves propelling abrasive particles (such as sand, glass beads, or aluminum oxide) at high velocities using compressed air or a centrifugal wheel | Dry ice blasting uses pellets of solid carbon dioxide (CO2), which are non-abrasive and sublimate directly from a solid to a gas |

| Laser parameters such as wavelength, pulse duration, and intensity can be adjusted to target specific contaminants and surface materials | Different types of sandblasting equipment include pressure blasters, gravity-fed blasters, and siphon blasters | Dry ice pellets create thermal shock due to the extreme temperature difference and cause contaminants to contract and loosen from the substrate |

| Common lasers include fiber lasers, CO2 lasers, and Nd: YAG lasers | Not only cleans but also roughens the surface, improving adhesion | The sublimation of dry ice leaves no secondary waste, and CO2 is a non-toxic |

| This process removes the contaminants without damaging the underlying substrate | The physical impact effectively removes rust, paint, and other surface coatings | Unlike sandblasting, dry ice blasting does not abrade the surface |

Types of Materials Cleaned

All three methods are versatile and offer cleaning for a wide range of materials. Let’s take a look at the availability of the materials for each technology.

Laser Cleaning

Laser cleaning is more popular for material coverage. This method works almost in every industry. Laser cleaning ensures minimal waste making it popular among others.

Materials suitable for laser cleaning are,

• Metals

• Stone and Concrete

• Historical Artifacts

• Electronic Components

Sandblasting

Sandblasting uses abrasive materials as the cleaning agent. Therefore, it tends to decay the surface layer with some materials. But materials that are best cleaned by sandblasting are,

• Heavy-duty Surfaces

• Metal Surfaces

• Concrete and Masonry

• Automotive Applications

Dry Ice Blasting

Cleaning sensitive materials requires less abrasion with cleaning particles. Dry ice blasting is suitable for sensitive surface cleaning jobs. Ideal material and surfaces for sandblasting are,

• Sensitive materials, plastic, rubber

• Food and beverage industry

• Electrical components

• Historic restoration

Cleaning Effectiveness: Laser cleaning vs. sandblasting vs. dry ice blasting

There are some identical differences in cleaning effectiveness between these three cleaning methods. We have mentioned them briefly side by side.

| Laser Cleaning | Sandblasting | Dry Ice Blasting | |

|---|---|---|---|

| Rust removal | Laser cleaning effectively removes rust from metal surfaces by vaporizing the corrosion without damaging the underlying metal | Sandblasting is highly effective in removing heavy layers of rust and corrosion from metal surfaces through abrasive action | Dry ice blasting can remove light to moderate rust from metal surfaces without causing damage |

| Paint removal | Laser cleaning can remove paint from surfaces without affecting the substrate | Sandblasting can strip multiple layers of paint or coatings from surfaces | efficiently removes paint and coatings from various surfaces without leaving behind residue or secondary waste |

| Organic residue | Efficiently removes organic residues such as grease, oil, and coatings without leaving residue behind | Removes organic residues but may not be as effective as other methods for delicate or intricate surfaces | highly effective in removing organic residues such as grease, oil, and food contaminants from surfaces |

Safety Considerations!

Laser cleaning, sandblasting, and dry ice blasting are all three types of cleaning methods that ask for some safety considerations. It is wise to ensure necessary safety protocols for both the workers and the environment. Here we are giving a combining safety suggestion for all three types of cleaning jobs. Following these steps can certainly save you from severe hazards and damage.

1. Eye Protection: To protect eyes from accidental exposure to laser beams, flying debris abrasive particles, and dry ice pellets safety goggles are a must.

2. Skin Protection: Operators should wear long sleeves and gloves to prevent direct contact with laser beams, dry ice pellets, and abrasive particles from sandblasting.

3. Ventilation: Proper ventilation is necessary for both laser cleaning and dry ice blasting. In particular, laser cleaning requires an additional ventilation system installed due to the chance of catching fire in the workplace.

4. Hearing Protection: The high-pressure air used in sandblasting produces loud noise levels, requiring operators to wear hearing protection to prevent hearing damage.

5. Environmental Impact: Consider the environmental impact of all three types of cleaning methods. Ensure proper disposal of chemical components to reduce environmental hazards.

Portability and Ease of Use

The mobility and usability of a cleaning machine allow it to do more. Here we have a brief discussion on the portability of the components and usability of all three cleaning methods.

| Laser Cleaning | Sandblasting | Dry Ice Blasting |

|---|---|---|

| Laser cleaning equipment is compact and available in various sizes, including portable and handheld devices | Sandblasting equipment can vary in size and complexity, ranging from small, handheld units to large, industrial-grade machines | Dry ice blasting systems are typically compact and lightweight, allowing for easy maneuverability and transportation |

| May be powered by batteries or generators, allowing for operation in remote locations or areas without access to electricity | Setting up sandblasting equipment requires trained personnel and additional setup time. | Requires minimal setup and preparation, as they do not require water, chemicals, or abrasive media |

| cleaning units can be transported easily to different work sites | Portable sandblasting units will require wheels or handles for transportation, while larger systems may need specialized vehicles or trailers for mobility | Equipment can be easily transported to different locations, making it suitable for both on-site and off-site cleaning applications |

Industrial Applications of Laser Cleaning, Sandblasting, and Dry Ice Blasting

Advanced cleaning technologies have made the cleaning industry versatile and easy to grow. Laser cleaning machines, sandblasters, and dry ice blasters are highly used tools of cleaning. Industries are evolving with these technological features.

Industrial applications of laser cleaning, sandblasting, and dry ice blasting are briefly mentioned below.

Industrial applications of laser cleaning

⇲ Automotive Industry.

⇲ Aerospace Industry.

⇲ Marine Industry.

⇲ Historical Restoration.

Industrial applications of sandblasting

⇲ Construction Industry.

⇲ Manufacturing Sector.

⇲ Shipbuilding and Maintenance.

⇲ Oil and Gas Industry.

Industrial applications of dry ice blasting

⇲ Food and Beverage Industry.

⇲ Electronics Manufacturing.

⇲ Power Generation Sector.

⇲ Medical and Pharmaceuticals Industries.