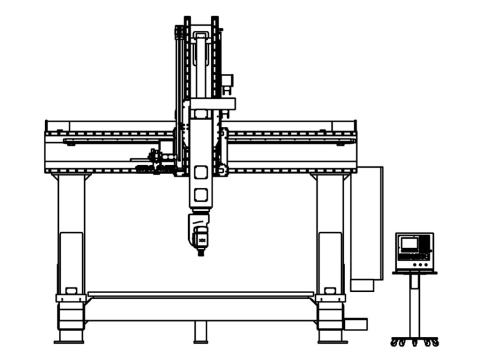

Based on the OPENcontrol CNC paltform, OPENMill is a modern and flexible system managing the most simple, up to the more complex 5 axis roto-translated plane CNC machines. The high integration between the OSAI OPENMill modular control system components for 5 axis CNC machine, guarantees productivity, high finishing quality and ease of use.

The solutions offered by the new OPENMill systems simplify installation and commissioning, optimizing the time-to-market thanks to the most advanced Software modules and Hardware components:

● HMI software with conversational Editor for on board programming of 2D machining and graphic control program execution

● Look ahead with 1024 pre-calculated blocks

● Algorithms for High Speed Cutting (HSC)

● Jerk control using advanced algorithms

● Spline algorithms on 5 axis

● Complete management of the 5 axis by using Tool Centre Point (TCP) programming

● Selection of the active kinematics from part program

●Volumetric compensation of both mechanical asymmetries and machine misalignments (Volumetric Compensation)

● Gantry and dual axis management

● Management of tool magazines, tool life, random tool, multi-pocket tool

● Different operator panel solutions

● Latest generation of OPENcontrol CNC

● Modular drives with rack structure for axis and spindle, with network recover, connected via Mechatrolink III fieldbus

● High performing brushless motors with absolute transducer

● Remote I/O connected via EtherCAT fieldbus

OSAI OPENMill Software

The OPENMill software is the intuitive and direct ambient that programs and controls the machining centre managing the execution of programs from either an external CADCAM or locally using graphic and parametric programming of cycles and profiles. The programmer does not require any knowledge of ISO language used by the CNC, thanks to the simple to use integrated conversational editor. Once the machining cycle is selected, the user is graphically helped in filling the parameters required, i.e. for a drilling matrix, linear tapping, slot milling or for milling of a profile defined by the user.

OPENMill is also the new OSAI HMI interface for milling. The end-user ambient, designed to optimize the CNC use, requires few commands, from soft-key of Touch Screen, to use all the main CNC functions. It also has integrated graphics for part preview and for outlining the parts already machined. A specific section of the interface allows the system customization via the graphic and functional definition of the screen buttons.

The OPENMill software perfectly matches the OPENcontrol Software configured as OPEN-20 and includes all the functions required to control machines with up to 4 interpolated axis:

● Axis:

• Coordinated, Spindle, Auxiliary

• Rotary and Linear, also Rollover type

• Gantry and Dual axis

• Geometric errors offset on single axis and on work planes (Cross compensation)

● Tool magazine:

• Linear, Planar and Revolver magazines

• Management of tool with fixed and random positions

• Life tools and alternative tools management

• Tool and offset configurable tables

● Movement:

• Linear, Circular, Helical, Spline movements

• Acceleration/deceleration parameters independent for each axis

- Acceleration trapezoidal and sinusoidal ramps with Jerk limitation

- Look Ahead (up to 1024 program blocks)

- Filters on programmable axis movements

- Velocity Feed Forward (VFF) - Zero Shift

- Multi Block Retrace

- Restart from interrupted programs

● Conversational editor:

• Drilling & tapping standard cycles

• Milling standard cycles

• Definition of open/close milling profiles

For CAD programming, the solution is the OPENcontrol software configured as OPEN-30, specifically designed for complex machines with 5 or more interpolated axis at the same time and up to 64 axis controlled, adds to the OPEN-20 the following features:

● Tool Centre Point (TCP)

● TCP for Double Twist and Prismatic heads with 2 or 3 rotary axis, for tilting tables and non-standard kinematics

● TCP with spline (High Speed Machine)

● TCP on rotated planes

In this case the system executes complex programs for 3D machining also on several channels at the same time (multi-process) for the machining with different independent heads.

PLC applications for Milling Machine and 5 axis CNC machine

The real-time SoftPLC, integrated in the CNC, is extremely versatile. This is a development ambient with several functions available, to interface the control with any type of machine. The performances:

● Multitasking real-time execution

● Up to 250 task with 10 priority levels

● Cycles task, with 250 µSec minimum scheduling

● More than 450 functions available

● Possible to include external software algorithms implemented with high-level languages

● For more standardized machines, OPENMill has a default configurable application that allows, with minimal customization, machine commissioning in a very short time.

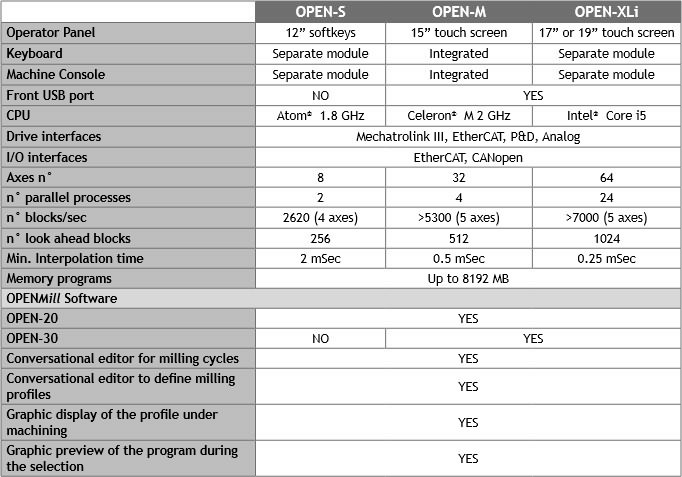

Numerical Control

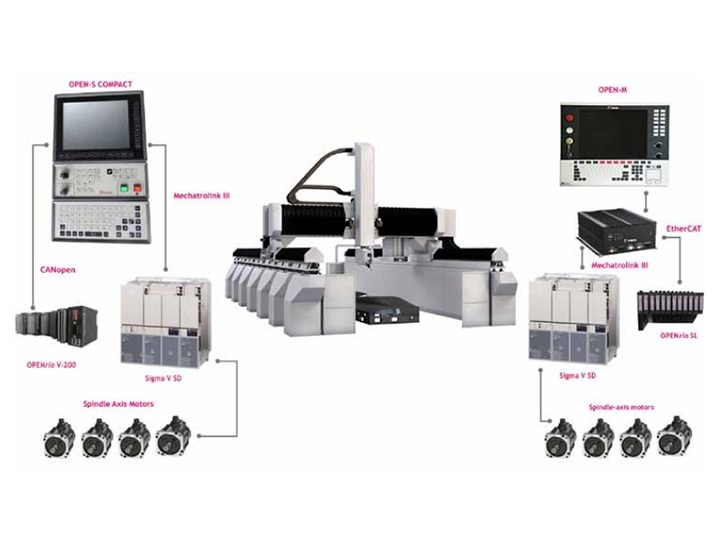

The OPENcontrol family of CNC’s are scalable and with a computing power easily adaptable to any customised requirement with no modifications to the software or the application.

The OPEN-S COMPACT with 12’’ operator panel is designed to control mediumcomplex machines. The user interface is softkey based and guarantees the ease of use of the system. All the buttons of the OPEN-S COMPACT are full stroke type to guarantee the full perception of the operation done.

The OPEN-M model, with OPENconsole COMPACT 15'' touch screen operator panel, is a CNC that suits more complex machines such as multi-axis 5 axis CNC machine.

The system consists of an operator panel with integrated keyboard and customizable console, and indipendent CNC, to be installed in the electric cabinet.

The OPEN-XLi model has a structure similar to the OPEN-M but, thanks to the i5 CPU, is the solution that best fits 5 axis CNC machine, where high performances are required. OPEN-XLi can be completed with the OPENconsole operator panel.

Configuration of the OPENcontrol systems using OPENMill technology.

OPEN-S COMPACT 12''

OPENconsole COMPACT 15''

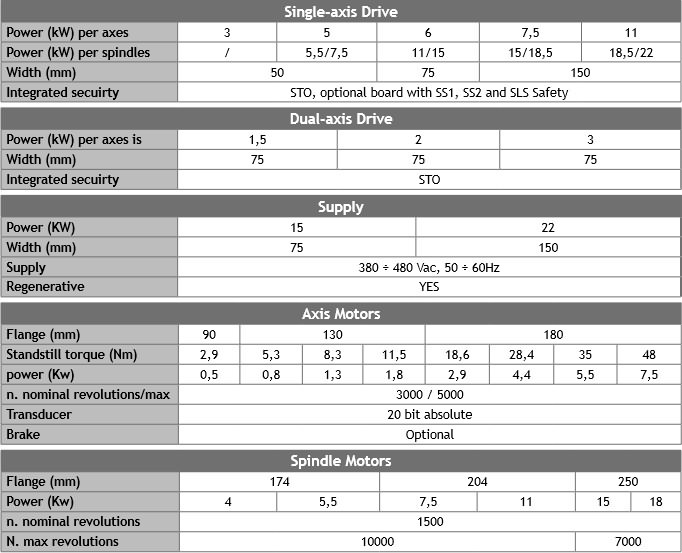

Servo drives and Servo-motors

The OPENMill solution requires the use of modular drives with up to 480 VAC power supply, CNC interfaced via Mechatrolink III fieldbus, that guarantees high speed data exchange from CNC to drives.

Only one regenerative power supply, with power up to 22kW at 480V, is used for both axis drives and the spindle drive. The power supply also features a 350% high overload capability for 3 to 5 seconds to improve the dynamic performance during axis acceleration.

The drives, with power up to 11kW for axis and 18kW for spindles, are equipped with integrated Safe Torque OFF and the possibility to manage the main Safety Integrate.

The servo motors with medium inertia and continuous torque from 3 to 48 Nm, are equipped with absolute transducer with 20 bit resolution. With maximum torque up to 3 times nominal torque and motor speeds up to 5,000 rpm.

Spindle motors, from 4 to 18 kW and speeds up to 10,000 rpm, allow all the metal removal machining typical of 5 axis CNC machine.

OPENconsole 17'' or 19''

Configuration scheme of the OPENcontrol systems using the OPENMill technology

Retrofit kit

The OPENMill solution technology, characterized by a high configurability and modularity level, match different retrofit solutions to upgrade milling machines and 5 axis CNC router machines. The modules allow the option to replace only the CNC or the complete control chain of the machine, from the HMI up to servo-motors. The two solutions for standard Retrofit, both include the OPENMill sotware and are:

Retrofit Kit 1 (suitable for analog or P&D motors and drives already installed on the machine):

● OPEN-S CNC with 12’’ operator panel, keyboard and machine console or OPEN-M CNC with 15’’ integrated operator panel with touch screen, keyboard and machine console

● Analog and feedback encoder interface bridge module for axis drives and spindle, with analog and digital I/O

Retrofit Kit 2 (complete solution):

● OPEN-S COMPACT CNC with 12’’ operator panel, keyboard and machine console or OPEN-M CNC with OPENconsole COMPACT 15'' integrated operator panel with touch screen, keyboard and machine console with OPEN-M CNC

● Modular system of I/O OPENrio

● Sigma V SD drives

● Brushless spindle and motor axis

Technical Specifications

CNC

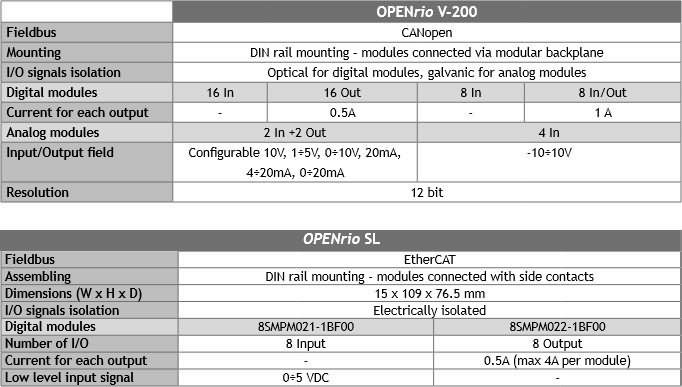

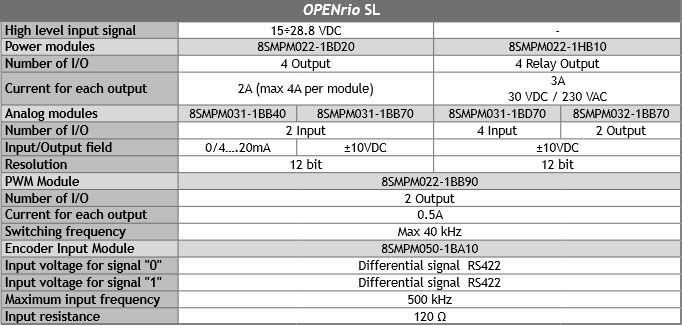

I/O MODULES

Drives and motors