5 Axis Laser Cutting Machine with 3D Robotic Arm

5 axis laser cutting machine with robotic arm is a type of 3D laser cutting system with Japan FANUC robot for 3D curved cutting of all types of metals.

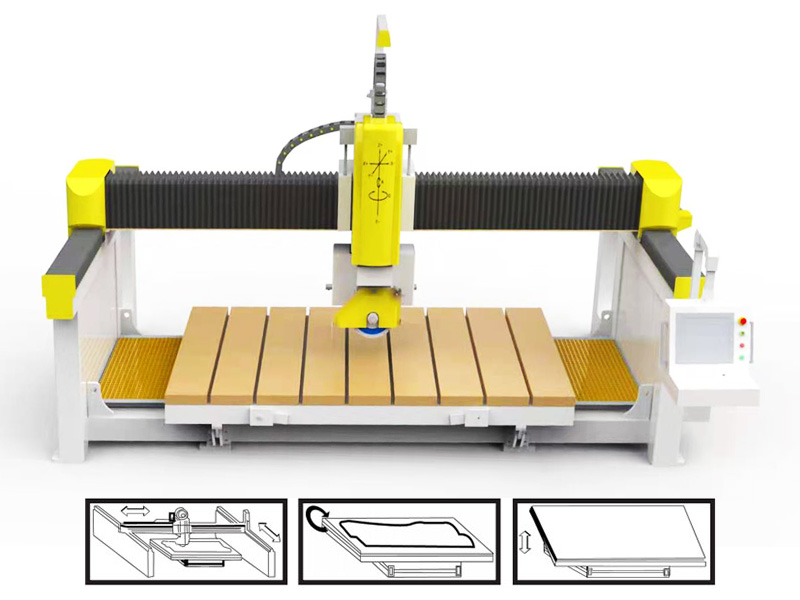

5 axis CNC bridge saw is a professional stone cutting machine for marble & granite cutting, edging, grooving, kitchen countertop making, special-shaped stone cut, and other occasions.

The biggest highlight of ordinary stone bridge cutting machine is that the equipment has powerful cutting ability, and 5 pieces of stone slabs no more than 20 mm can be superimposed and cut at a time. This cutting effect is not weak. But it is still slightly insufficient for the overall countertop processing.

There are many processing procedures for the countertop, and the stone sheet is only a part of it, such as heterosexual cutting, 45 ℃ edge trimming, drilling and polishing are not available, and it is impossible to use ordinary stone bridge cutting machines to complete all the procedures. In order to realize all the processes in one go, use the 5 axis CNC bridge saw to realize the completion of all processes at one time, make it easy to work, and make products that can meet the real needs of customers without secondary processing, saving manpower, reducing power consumption, and improving efficiency and enhance profitability.

5 axis CNC bridge saw adopts a computer control system, which can realize manual programming or PC programming and other methods to automatically complete processing operations. It can be convenient for stone cutting, edging, grooving, kitchen countertop processing, special-shaped processing and other occasions.

1. One-time positioning, all processes are completed at one time, and the accuracy and speed are guaranteed.

2. For heterosexual sawing, no matter what angle, five-axis multi-directional sawing and edging can be realized.

3. The automatic tool change spindle can realize the simultaneous completion of processing and engraving. The supporting tools include automatic switching of saw blades, milling cutters, forming wheels and polishing wheels, and the functions of cutting, chamfering and polishing can be completed at one time without repeated positioning, and the machining accuracy can be improved, enhance the processing efficiency in the processing quality.

4. Five-axis linkage cutting ensures cutting speed and cutting accuracy.

5. The machine head can be freely swung 360 degrees, and can be used for cutting and chamfering at any angle and shape for the plate: horizontal cutting, vertical cutting, arc cutting, oval cutting, and non-standard cutting of the opposite sex are supported respectively.

6. Five-axis grinding, standard shape grinding can be carried out through the forming wheel, and it can also support heterosexual grinding.

7. In addition to the cutting shape, it can also be used for cutting materials for large plates, changing the pan into a straight knife and performing five-axis carving, and hollowing out the opposite sex.

8. Hydraulic development platform, support 85-degree turning, convenient and labor-saving loading and unloading.

9. No need for professional programming, CAD drawings automatically generate processing files

10. After the polishing wheel is configured, the table top can also be ground and polished.

11: Substitute labor to save labor and achieve profitability.

5 axis laser cutting machine with robotic arm is a type of 3D laser cutting system with Japan FANUC robot for 3D curved cutting of all types of metals.

You will understand how does a 5 axis CNC router machine cut foam as 3D car mold in this video. It is a multi axis CNC machining center for 3D mold making.

Large format 5 axis CNC router machine for foam milling & routing is used to cut 3D shapes out of EPS foam, styrofoam, polyethylene, or polyurethane.