It's my first time to buy goods from abroad, but I have to say I got one good experience for the oversea purchase from STYLECNC. In terms of using the five-axis CNC machine, they offer free online training for assembly and operation. Getting started and connecting it to the PC is very easy, and it runs smoothly and cuts are made with precision.

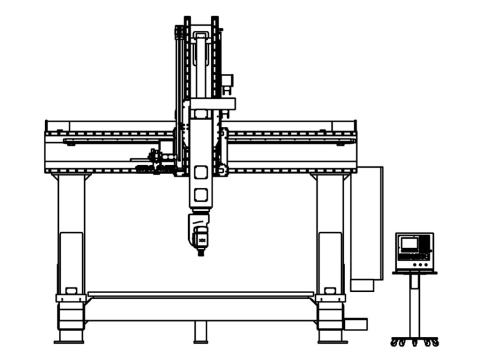

Large Gantry 5 Axis CNC Machine for 3D Molding

Large gantry 5-axis CNC machine is a heavy-duty industrial CNC machining center fortrimming formed parts, aerospace, molds, patterns, composites, automotive, large envelope parts, other 3D surface milling and 3D shape cutting projects. Now the large format five-axis CNC router machine for sale at cost price.

- Brand - STYLECNC

- Model - STM2040-5A

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 6' x 12' (72" x 144", 2000mm x 4000mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

The STM2040-5A is a heavy-duty 5-axis CNC machine with a 10KW Italian HSD 5-axis spindle, OSAI Control system, Yaskawa Servo motor, and driver. The Z-axis travel can be heightened to 2.1 meters, and the German original rotating arm ensures the accuracy and strength of the machine. It is mainly used for large metalloid molds, automotive foam molds, rail wooden molds, wooden mold trains, wooden ship models, wooden model aviation, 3D surface carving, and 3D shape cutting.

5 Axis CNC Machine Features

• The STM2040-5A 5-axis CNC machine uses a 10KW Italian HSD Spindle(HS655-ES789) with high precision and great strength.

• THK Linear Guide from Japan: large load bearing and stable running.

• Apex gearbox reducer.

• High precession TBI ball screw from Taiwan for Z axis.

• Drum style auto tool change with 8 positions.

• OSAI controller system: does not need a computer, simple operation, and good independence; you can also choose another option: Taiwan SYNTEC control system.

• Japan YASKAWA servo motor driver: steady working capability and high positioning precision.

• Schneider Electronic spare parts.

Five Axis CNC Machine Advantages

• OSAI numerical control system, the machine is of high speed and high machining accuracy. The German original rotating arm ensures the accuracy and strength of the machine.

• The intelligent processing cross-border protection function can prevent the excessive process caused by mechanical collision.

• Z-axis travel can be heightened to 2.1 meters, so it is very suitable for processing large-scale three-dimensional surfaces.

• Diversified control processing speed can control the working speed, traveling speed, and dropping tool speed, and it improves the quality and efficiency greatly.

• Top-quality components, to make the machine high-precision and high-efficiency. HSD ATC spindle, Delta inverter, TBI ball screw, Yaskawa servo motors, OSAI control system, and so on, which keep the machine in the best condition even after working for many years.

• Strong machine body, reliable and durable, with a long working life.

• Diversified control processing speed can control the working speed, traveling speed, and dropping tool speed, and it improves the quality and efficiency greatly.

• Easy and safe operation and low maintenance cost. To help you learn quickly how to operate safely the machine, free training in our factory will be offered. Less time and less money will be spent on maintenance because of the top quality of the machines.

• Humanized and beautiful design. Breakpoint-specific memory to keep the carving status when power is off, processing time forecast, and other functions in case of accidental power outages. Stop Emergency Buttons, and emergent shutdowns during unexpected accidents and do not harm humans. The intelligent processing cross-border protection function can prevent excessive processes caused by mechanical collision. Colorful machines’ appearances and high-quality paint make the machine beautiful.

• High-speed machining and smooth motion are achieved using a state-of-the-art OSAI control system.

• Many optional configurations and OEM services are available. According to your requirements, different configurations will be offered. OEM service is available for you.

5 Axis CNC Machine Technical Parameters

| Model | STM2040-5A | |

| Movement type | Movable gantry | |

| Working area(MM) | 2000*4000*900 | |

| Travelling | C Axis | ±213° |

| A Axis | ±120° | |

| Beam spacing(MM) | 2750 | |

| Beam Height(MM) | 1500 | |

| Double pendulum head type | HS655 | |

| Supplier for Double pendulum head | HSD | |

| Output power of Spindle | 10KW | |

| Spindle speed | 22000 RPM | |

| Servo system | YASKAVA Servo system | |

| Inverter | Delta inverter | |

| Table size (MM) | 2000*4000mm | |

| Material of Table | Aluminum Profile | |

| Tool magazine | Rotary tool magazine (8 positions) | |

| Cutter specifications | HSK F63 | |

| Control system | OSAI / SYNTEC | |

| Programming Software | AlphaCAM | |

| Machine size | 4260*2150*3300MM | |

| Total weight | 12T | |

| Total Power(KW) | 30KW | |

| Voltage | AC 3P 380V 50HZ | |

| Efficiency File Conversion(hr/day) | 0.5 | |

| File Exchange | USB | |

| Equipment data storage and capacity | Cable transmission, USB, CF | |

| Maximum speed: | X Axis | 40m/min |

| Y Axis | 40m/min | |

| Z Axis | 20m/min | |

| C Axis | 2700°/min | |

| A Axis | 2700°/min | |

Applications of 5-Axis CNC Machines

5-axis CNC machines offer unmatched versatility and precision, making them essential in various industries. Their ability to work on complex shapes and surfaces ensures high-quality results for intricate and large-scale projects. Here are their primary applications:

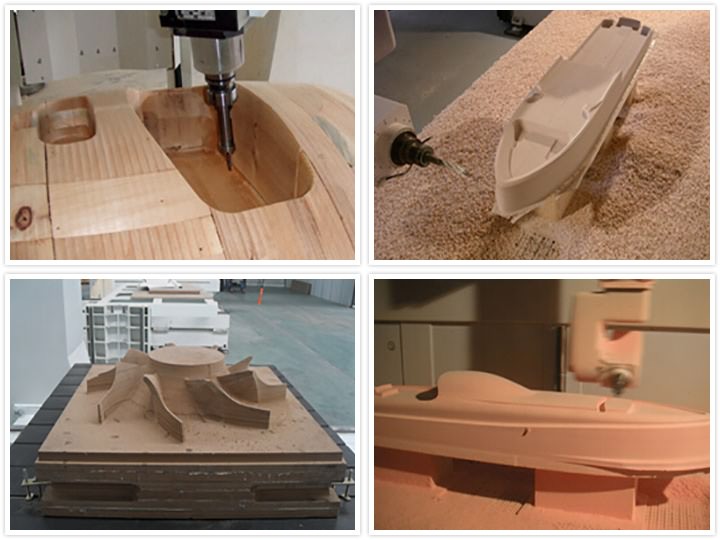

Mold Industry

5-axis CNC machines are widely used for creating large metalloid molds, automotive foam molds, and wooden models for ships, aviation, and trains. They excel in crafting intricate designs with precision, ensuring durability and accurate replication for manufacturing processes.

Instrument Industry

In the instrument industry, these machines handle 3D surface engraving and shape cutting for large-scale instruments. Their precision allows for the creation of detailed components essential for producing functional and aesthetically pleasing instruments with complex geometries.

Furniture Industry

These machines are ideal for manufacturing cabinet doors, wooden doors, solid wood furniture, stereo boxes, computer desks, and game cabinets. They ensure smooth cuts, intricate designs, and efficient production, catering to both mass production and custom furniture designs.

Decoration Industry

5-axis CNC machines are perfect for processing materials like acrylic, PVC, density board, stone, organic glass, and soft metals like aluminum and copper. Their precision and versatility make them ideal for creating decorative elements for interiors, signage, and artistic projects.

Five Axis CNC Machining Projects

How 5-Axis CNC Machines Enhance Precision and Efficiency in 3D Machining

5-axis CNC machines are revolutionizing 3D machining by offering unparalleled precision and operational efficiency. These advanced machines are designed to tackle complex geometries and reduce production time, making them indispensable across various industries. Here's how they achieve this.

Reduced Setup Time

5-axis CNC machines can perform multiple operations in a single setup, eliminating the need to reposition the workpiece. This reduces production time and minimizes human error during realignment. The seamless transitions between operations enhance overall machining accuracy. Fewer setups also reduce downtime, boosting production rates significantly.

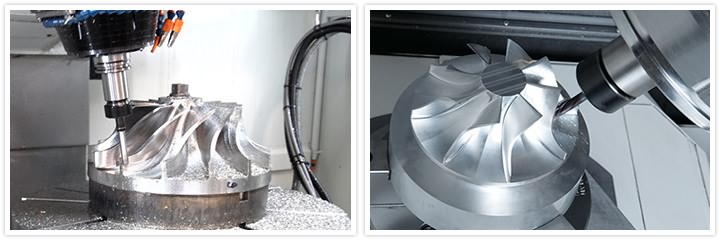

Improved Access to Complex Geometries

These machines allow cutting tools to move along five axes, providing better access to hard-to-reach areas. This capability is ideal for creating intricate shapes and contours, ensuring precision in manufacturing complex components such as molds, aerospace parts, and medical instruments. Their ability to handle undercuts and deep pockets eliminates the need for additional tooling.

Enhanced Surface Finish

With their ability to tilt the tool or workpiece, 5-axis CNC machines reduce vibrations and tool chatter. This ensures a smoother surface finish, even on challenging materials. The improved finish eliminates the need for extensive post-processing, saving time and costs. This feature is particularly valuable when working with high-value materials that require a flawless appearance.

Higher Precision and Accuracy

The advanced control systems of 5-axis CNC machines allow for precise movements and positioning. This results in highly accurate dimensions and tighter tolerances, crucial for industries like automotive, aerospace, and medical device manufacturing. The consistent accuracy also enhances reliability in mass production scenarios.

Increased Efficiency and Productivity

By handling complex tasks with fewer setups and faster cutting speeds, 5-axis CNC machines boost overall productivity. Their efficiency allows manufacturers to meet tight deadlines without compromising quality. The ability to run continuously with minimal supervision further improves cost-effectiveness.

These capabilities make 5-axis CNC machines a game-changer in 3D machining, combining precision with operational excellence.

Maintenance Tips for Maximizing the Performance of Your 5-Axis CNC Machine

Proper maintenance is essential to keep your 5-axis CNC machine running at its best. Regular upkeep ensures smooth operation, reduces downtime, and extends the machine's lifespan, helping you maintain high performance for years to come.

• Regular Cleaning: Clean the machine after every use to remove dust, debris, and chips. This prevents buildup that can affect the machine’s performance and accuracy.

• Lubrication: Keep moving parts well-lubricated to minimize friction and wear. Regular lubrication ensures smooth motion and improves overall machine efficiency.

• Inspect Tooling and Components: Check tools and other components regularly for signs of wear or damage. Replacing worn parts promptly helps avoid issues and maintains cutting precision.

• Check and Tighten All Fasteners: Loose bolts or screws can cause vibrations, affecting the quality of cuts. Periodically tighten fasteners to maintain structural stability and accuracy during operation.

• Perform Calibration: Regularly calibrate the machine to ensure all axes are properly aligned. This helps maintain cutting accuracy and reduces errors in your workpieces.