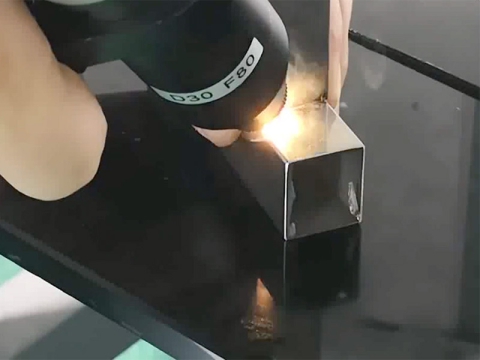

Laser Welding Machine for Square Stainless Steel Tube

This is a video of handheld laser welding machine with fiber laser source for square stainless steel tube welding, which is used for sheet metals & tubes.

Looking for a handled fiber laser welder for stainless steel, brass, and aluminum? Review the handheld laser welding machine with features of easy operating, welding seam perfect, high welding rates and without consumables.

The handheld fiber laser welding machine is applied in welding thin stainless steel, iron plate, aluminum plate and other metal materials. The handheld laser welding machine can perfectly replace the traditional argon arc welding and electric welding technology.

Laser welding has many technical advantages. Among these are: minimal heat into the part, ability to access confined areas, ability to weld inside closed gas or vacuum chambers (thru a glass window), ability to be transmitted over long distances using fiber optic beam delivery, able to shape the focused beam to fit specialized welding requirements, and many more. The main advantage to laser welding, however, is the ability to automate the welding process and take advantage of increased production rates. By computer controlling the laser, the power level, pulse shape, power ramping and other laser parameters, the process can be precisely controlled and monitored, allowing for production rates previously unachievable with conventional welding methods. While laser systems are generally more expensive than traditional methods, the cost savings achieved through higher production and lower reject rates can easily justify the additional cost.

This is a video of handheld laser welding machine with fiber laser source for square stainless steel tube welding, which is used for sheet metals & tubes.

This video shows how to use a handheld laser welding machine from start to weld, which is the best reference to help you buying a portable laser beam welder.