Laser Beam Welding

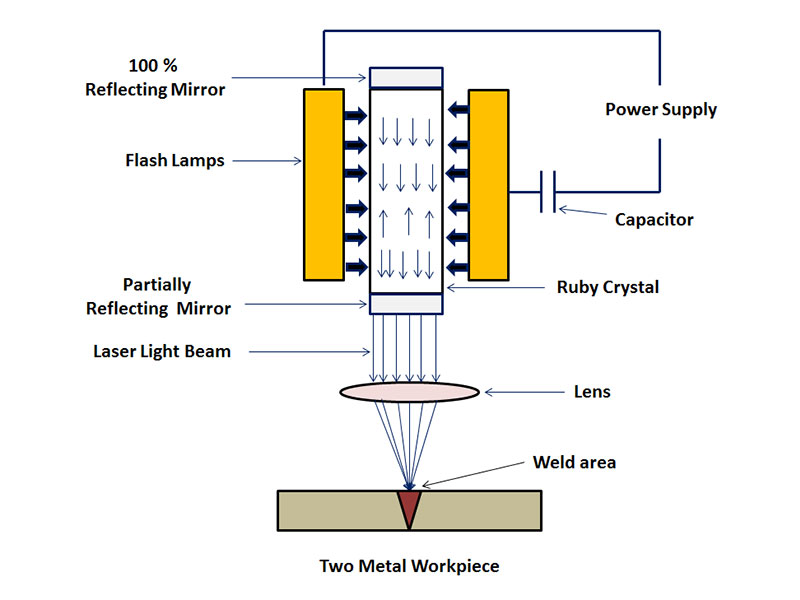

Laser beam welding is a high-efficiency and highly precise welding method using a high-energy-density laser beam as its heat source. Welding can be done by the continuous or pulsed beams of laser. According to the principles of laser welding, the processes can be further divided into two: heat conduction welding and laser deep welding. Power density below 104 ~ 105 W/cm2 refers to heat conduction welding. At that time, the penetration depth is shallow with slow welding speed; when the power density is larger than 105 ~ 107W /cm2, under the heat action, the metal surface takes the recess into "hole" appearance to form deep penetration welding.

Features

Features of Fast Welding Speed and Large Aspect Ratio

Laser beam welding generally uses continuous laser beams to complete the connection of materials. The metallurgical physical process is very similar to electron beam welding, that is, the energy conversion mechanism is completed by a "key-hole" structure.

Under sufficiently high power density laser irradiation, the material evaporates and forms small holes. This small hole filled with steam is like a black body, absorbing almost all the energy of the incident beam. The equilibrium temperature in the cavity is about 2500C. The heat is transferred from the outer wall of the high-temperature cavity, melting the metal surrounding the cavity. The small holes are filled with high-temperature steam generated by the continuous evaporation of the wall material under the beam of light.

The four walls of the small holes surround the molten metal and the liquid metal surrounds the solid material. (In most conventional welding processes and laser conduction welding, the energy is first (Deposited on the surface of the workpiece, then transported to the inside by transfer). The liquid flow outside the hole wall and the surface tension of the wall layer are consistent with the steam pressure continuously generated in the hole cavity and maintain a dynamic balance. The light beam continuously enters the small hole, and the material outside the small hole is continuously flowing. As the light beam moves, the small hole is always in a stable state of flow.

That is to say, the small hole and the molten metal surrounding the hole will move forward with the forward speed of the leading beam. The molten metal fills the gap left by the small hole and then condenses, and the weld is formed. All of the above process happens so fast that the welding speed can easily reach several meters per minute.

1. Laser beam welding is fusion welding, which uses a laser beam as the energy source and impacts the welded joint.

2. The laser beam can be guided by a flat optical element (such as a mirror), and then the beam is projected onto the weld seam with a reflective focusing element or lens.

3. Laser beam welding is non-contact welding. No pressure is required during the operation, but inert gas is needed to prevent oxidation of the molten pool. The filler metal is occasionally used.

4. Laser beam welding can be combined with MIG welding to form laser MIG composite welding to achieve large penetration welding, while the heat input is greatly reduced compared to MIG welding.

Applications

The laser welding machine is widely used in such high-precision manufacturing fields as automobiles, ships, airplanes, and high-speed rail. It greatly improved the quality of life for people and also propelled the home appliance industry into precision engineering.

Plasma Arc Welding

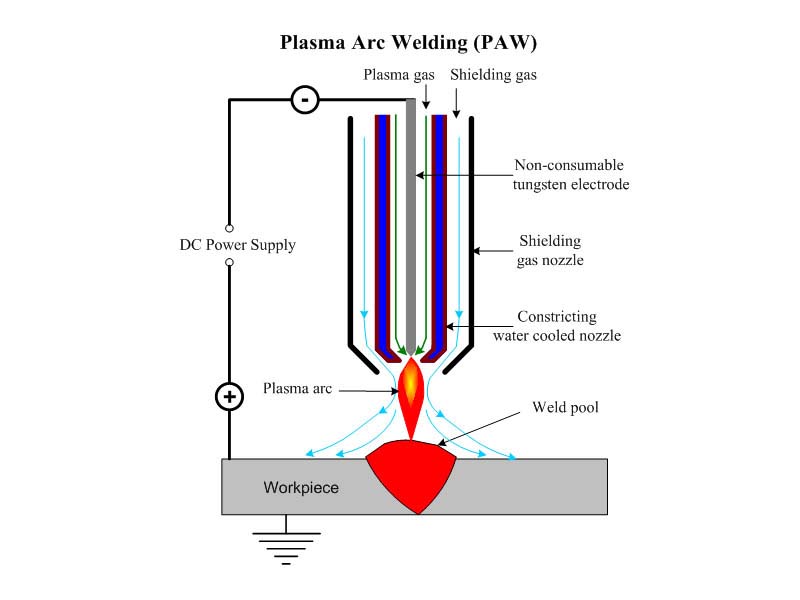

Plasma arc welding refers to a fusion welding method that uses a plasma arc high-energy density beam as a welding heat source. During welding, the ion gas (forming an ion arc) and the shielding gas (to protect the molten pool and welding seam from the harmful effects of air) are pure argon. The electrodes used in plasma arc welding are generally tungsten electrodes and sometimes need to be filled with metal (welding wire). Generally, the DC positive connection method is adopted (the tungsten rod is connected to the negative electrode). Therefore, plasma arc welding is essentially a tungsten gas-shielded welding with a compression effect.

Plasma arc welding has the characteristics of energy concentration, high productivity, fast welding speed, small stress deformation, and stable electrical isolation, and is suitable for welding thin plates and box materials. It is especially suitable for various refractory, easily oxidized, and heat-sensitive metal materials ( Such as tungsten, molybdenum, copper, nickel, titanium, etc.).

The gas is dissociated by the heating of the arc and is compressed when passing through the water-cooled nozzle at high speed, increasing the energy density and the degree of dissociation, forming a plasma arc. Its stability, calorific value, and temperature are higher than the general arc, so it has greater penetration and welding speed. The gas forming the plasma arc and the shielding gas around it generally use pure argon. Depending on the material properties of various workpieces, some use helium, nitrogen, argon, or a mixture of both.

Features

1. Micro-beam plasma arc welding can weld foils and thin plates.

2. With a small hole effect, it can better realize single-sided welding and double-sided free forming.

3. Plasma arc has high energy density, high arc column temperature, and strong penetration ability. It can achieve 10-12mm thick steel without bevel welding. It can be welded through double-sided forming at one time. The welding speed is fast, the productivity is high, and the stress deformation is small.

4. The equipment is relatively complicated, the gas consumption is large, the group has strict requirements on the clearance and the cleanliness of the workpiece, and it is only suitable for indoor welding.

Applications

Plasma welding is one of the important means in industrial production, especially for welding copper and copper alloy, titanium and titanium alloy, alloy steel, stainless steel, molybdenum, and other aerospace metals, which are used in military and other cutting-edge industries, such as the manufacture of a certain type of missile shell made by titanium alloy and partial thin-walled containers on aircraft.

Cost, Maintenance, and Operational Efficiency

Some factors related to comparing choices of technologies between laser beam welding and plasma arc welding for industrial applications include cost, maintenance, and operational efficiency.

Cost Analysis

Laser beam welding requires a high initial investment since the equipment is complicated compared to plasma arc welding. The worth of general industrial laser welding systems usually ranges upwards of $200,000, whereas plasma arc welding systems have costs somewhere in the range of $10,000 to $50,000. However, LBW has the potential for significant long-term cost savings thanks to increased processing rates as well as minimal post-weld finishes required. Plasma welding could have higher consumable costs for continued operation.

Maintenance Requirements

Because consumable parts, such as electrodes and gas nozzles, wear out more frequently, plasma arc welding systems usually require more frequent maintenance. By contrast, laser welding systems require fewer consumables, but their optics and laser sources do need occasional cleaning and recalibration. When properly maintained, laser sources can last for more than 20,000 hours with less down time. Plasma systems, although simpler, may experience more frequent interruptions since consumables wear.

Operational Efficiency

The welding techniques of laser are much faster and more accurate, reaching speeds of as high as 10 meters per minute on thin materials, hence very ideal for mass production. It also produces very minute heat-affected zones, hence giving minimal material distortion, thus improving the quality of the product. Plasma welding is effective in thicker materials, though at a slower speed, often needing additional finishing touches to clean up welds, such as grinding.

While laser beam welding requires higher investment costs upfront, its efficiency and less frequent need for maintenance often provide cost benefits in the long run, especially for applications requiring high precision. Plasma arc welding is still good for less complex work and smaller operations.