I'm a newbie to CNC, and I had been looking for a small CNC with tool changer to start my business. The STM6090C is capable of most of woodworking projects I wanted. Testing, buying, shipping, assembling, setting and debugging, all jobs have been done in 32 days. All in all, this is a great kit for beginners.

Small CNC Router Machine with Automatic Tool Changer (ATC)

Small CNC router with ATC (Automatic Tool Changer) kit and 2x3 table size is an entry-level CNC machine with a compact design for those who require automatic switching of multiple router bits for small-envelope projects, but don't have enough space for a larger computer-controlled machine tool.

- Brand - STYLECNC

- Model - STM6090C

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 2' x 3' (24" x 36", 600mm x 900mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Small-size CNC routers with ATC are powerful yet compact machines that are designed for accuracy and speed. They allow users to change tools automatically during machining-a function that increases productivity while minimizing manual interference. These routers undertake detailed cutting, engraving, and carving of various materials: wood, plastics, and metals, among others.

Their compact size makes them perfect for small workshops or limited spaces. With advanced features like ATC, they provide versatility, speed, and accuracy, making them a valuable investment for businesses and hobbyists alike.

Features of Small CNC Router Machine with Automatic Tool Changer (ATC)

1. The spindles have water-cooling or air-cooling for different usage, If you need to cut aluminum, it is better to use a water-colling spindle. If only for woodworking, the air-cooling spindle is better.

2. The CNC control systems have a Taiwan Syntec controller, DSP controller, and Mach3 controller, it depends on the price and functions.

3. T-slot table and vacuum table for choice.

4. Welded structure by thick square steel stabilized under high temperature, ensures minimum distortion, excellent rigidity, and powerful strength.

5. Automatic lubricating system, one touch can finish periodic maintenance easily.

6. Internationalized directives ensure that it is compatible with CAD/CAM software like Type3, Artcam, Castmate, Proe, UG, and Artcut.

7. Linear automatic tool changer system with 5 tools storage.

Applications of Small CNC Router Table with Automatic Tool Changer (ATC)

The small CNC router kit is used for milling and cutting wood, MDF, acrylic, artificial stone, artificial marble, bamboo, organic boards, double-color boards, PVC boards, aluminum, brass, and other materials.

The small CNC router table is typically used in the woodworking industry, stone industry, advertising industry, artwork or decoration industry, electronica industry, mold industry music industry, and more.

Technical Parameters of Small CNC Router Machine with Automatic Tool Changer (ATC)

| Model | STM6090C |

| Table Size | 2x3 (600x900x200mm) |

| Machine Body | Welded square tube |

| Table Surface | Vacuum table + 5.5kw vacuum pump |

| Z Axis | Taiwan TBI ballscrew transmition |

| X, Y Axis | Helical rack and pinion transmission |

| Spindle | 2.2KW water-cooled spindle (3KW for option) |

| Spindle Speed | 24000 RPM |

| Drive Motor | Stepper motor |

| Max. Rapid Travel Rate | 16000mm/min |

| Max. Working Speed | 8000mm/min |

| Controller System | Mach3 |

| Software | Type3, ArtCAM, Ucancam |

| Command | G-code |

| Machine Precision | 0.01mm |

| Repositioning Precision | 0.03mm |

| Working Voltage | AC220/380V |

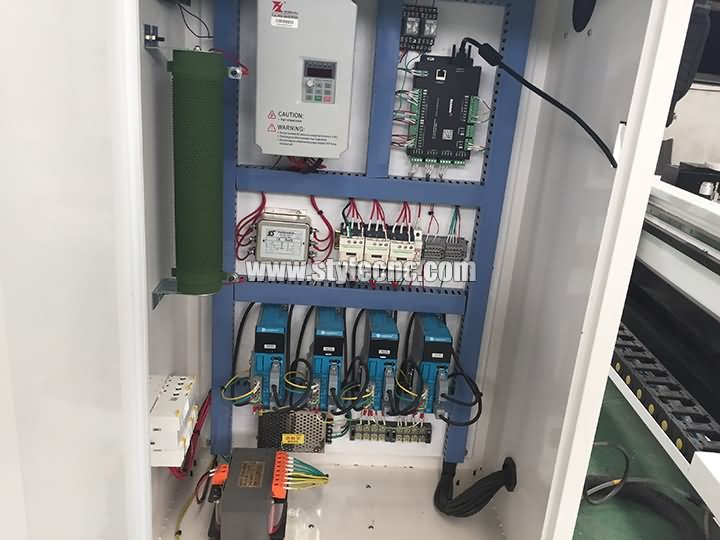

Details of Small CNC Router Kit with Automatic Tool Changer (ATC)

DSP controller, easy to use for beginners.

Vaccum table to adsorb materials when cutting and carving.

The electronic box to control the machine's working.

5pcs linear automatic tool changer storage.

High sensitive tool sensor to automatic measure the distance between tool and material.

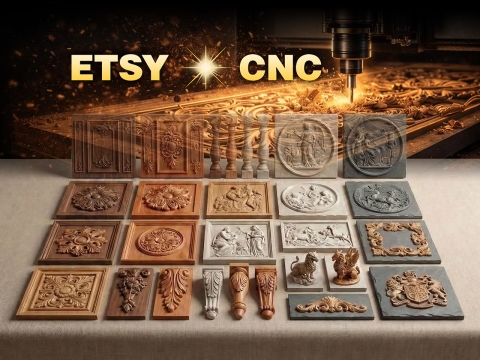

Projects of Small CNC Router Machine with Automatic Tool Changer (ATC)

The ATC CNC router table sizes can be customized based on your working requirements, allowing for options of 2x3 (600x900mm), 4x4 (1200x1200mm), 4x8 (1300x2500mm), 5x10 (1500x3000mm) and 6x12 (2000x4000mm).

How to Choose the Best Small CNC Router with ATC?

Choosing the right small CNC router with an Automatic Tool Changer (ATC) is crucial for efficiency and quality in your projects. Consider factors like machine specifications, features, and your budget to make an informed decision. Below are key points to guide you:

1. Assess Your Project Requirements

Identify the materials you shall be working with, such as wood, plastic, or metal, and how complex the designs are. A CNC router with proper spindle power and cutting capability will produce highly accurate results on your projects. If your projects happen to contain very intricate designs, then choose a machine that can manage high precision with great speed.

2. Check the Build Quality

Look for a router made from solid materials, like aluminum or steel. A solid frame minimizes vibrations and promotes accuracy in cuts, which is very important in its long-term performance and reliability. Robust construction also ensures the machine can handle demanding workloads without compromising performance.

3. Evaluate the ATC System

Ensure the Automatic Tool Changer can handle multiple tools efficiently. Check for compatibility with your tools and the speed at which it changes, as this impacts overall productivity during operations. A well-designed ATC system minimizes downtime and simplifies complex projects by automating tool changes seamlessly.

4. Review the Control System and Software

Opt for a CNC router with user-friendly software and an intuitive control panel. Compatibility with CAD/CAM programs makes design and execution seamless, especially for beginners. Ensure the software supports updates and has robust features for advanced users as well.

5. Consider Your Budget

Compare prices and look for a balance between features and cost. While investing in quality is important, ensure it fits within your budget to maximize value without overspending. Research financing options or promotional offers to make the purchase more affordable if necessary.

6. Verify After-Sales Support

Good customer service coupled with good technical support will ensure maintenance and troubleshooting are performed. Always seek out brands offering comprehensive warranties and responsive assistance. Reliable support means smooth operations with minimal downtime in case of unforeseen issues.

Maintenance Tips for Small CNC Routers with ATC

Correct maintenance is what will keep your small CNC router with ATC going for a long time and at an optimum level. Regular maintenance limits downtimes, saves from expensive repairs, and gives precision for each job. The following tips should be followed in order to keep the optimum quality of the machine:

Regular Cleaning

• Remove dust, debris, and leftover material from the router bed, spindle, and tool changer after each use.

• Use a soft brush or vacuum to clean sensitive parts and prevent blockages that could impact performance.

Lubricate Moving Parts

• Apply lubricants to rails, screws, and bearings as recommended by the manufacturer.

• Regular lubrication ensures smooth movements and reduces wear on components over time.

Inspect the Tool Changer Mechanism

• Check the ATC system regularly for proper alignment and functionality.

• Ensure tool holders are clean and securely fastened to avoid errors during tool changes.

Calibrate the Machine Periodically

• Perform calibration tests to maintain cutting precision.

• Adjust settings if you notice any deviations in accuracy or alignment.

Monitor Electrical Components

• Check cables, connections, and wiring for any signs of damage or wear.

• Keep the control panel clean and ensure the machine operates within the specified voltage range.

Replace Worn Tools

• Inspect cutting tools frequently and replace dull or damaged bits.

• Sharp tools enhance cutting quality and reduce strain on the spindle.

Follow Manufacturer’s Guidelines

• Adhere to the maintenance schedule and recommendations provided in the user manual.

• Use only authorized parts and accessories to prevent compatibility issues.

Is a Small CNC Router with ATC Worth It?

The small CNC router with ATC brings much-desired efficiency and precision to work. The ATC enables smooth operations by automatically changing the tools, hence saving time and energy expended in doing so. This is particularly helpful for a company or workshop dealing in complicated designs or voluminous work.

The ATC-equipped CNC router saves productive time by minimizing losses between tool changes. Capable of quickly and accurately changing tools, the consistency of quality is maintained with regard to multiple tasks, while further reducing human error for precise cuts and engravings, especially for detailed projects, such as furniture making and customized signage.

Although the cost of the initial investment in a CNC router with ATC is greater than that of the regular model, the long-term benefits surely pay off. Its speed, reliability, and versatility surely promise to increase manifold your output and profitability, hence a very worthy addition to any small business or even a hobbyist's workshop.

Why Choose STYLECNC?

STYLECNC is a leading CNC machine manufacturer with over 20 years of experience. It offers a wide range of high-quality products, including CNC routers, laser engravers, and plasma cutters, among many more. With its innovative focus, STYLECNC serves customers around the world with excellent services at affordable costs. Reasons for choosing STYLECNC:

• More than 20 years of professional manufacturing experience in CNC machines.

• Quality products at competitive prices.

• Reliable after-sales support and customer satisfaction.

• Trusted by customers in over 180 countries.

Braden Todd

Abdullah

يعمل جهاز التوجيه CNC الصغير جيدًا للمبتدئين أو لمتجر أصغر. يبدو أن جميع الأجزاء جيدة الصنع وذات جودة عالية. بشكل عام ، أعتقد أنها آلة رائعة بسعر معقول جدًا.

Terseer

I don't write reviews often, but I have to say this may be one of the best purchases I have made in a while. It's a real solid piece of equipment. The small CNC works wonderfully with tool changer, I would definitely recommend.

Gagandeep Singh

I have now owned this small CNC router machine for almost 5 months. I use it on a daily basis and have made well over 2000 items, the machine is still going well. I am very satisfied.