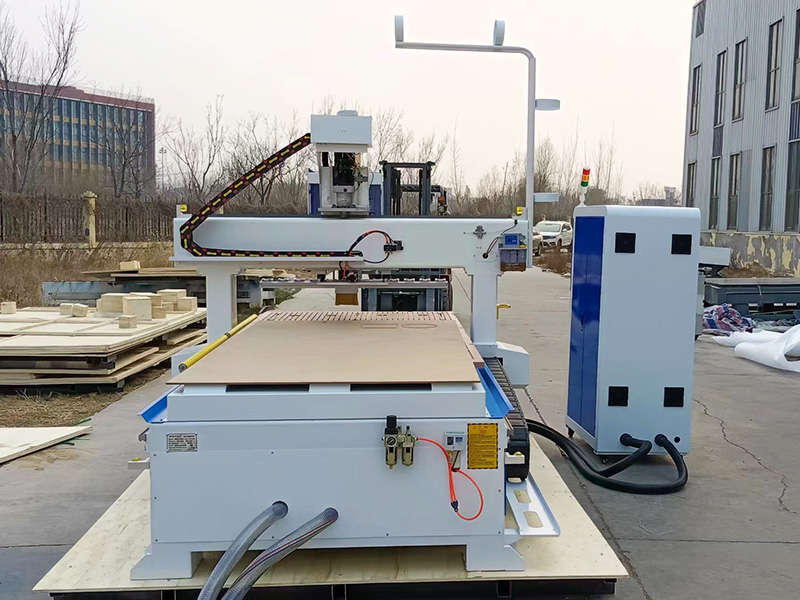

The STM1325C arrived well packaged and exceeded my expectations. Mechanically, this CNC machine is well-built, with all parts pre-assembled. Assembly was pretty painless - I had it unboxed and put together in about half an hour following the included manual. The CNC controller software is user-friendly, and is easy to operate for anyone, whether beginner, intermediate or experienced. After a week of testing, this STM1325C has proven itself to be an excellent choice for woodworking automation, particularly cabinet making. I was also impressed by its linear ATC kit, which automates tool changing, freeing my hands while increasing productivity. In my personal experience, this is a quality CNC router worth buying.

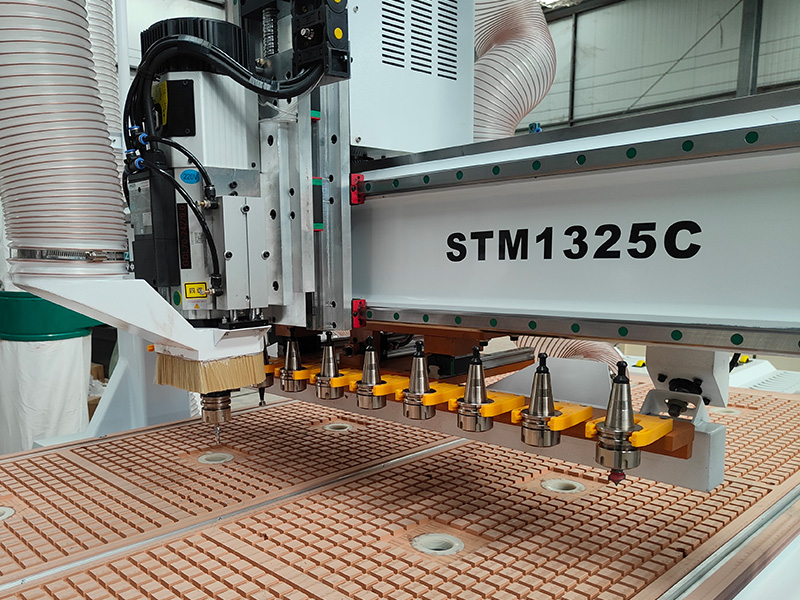

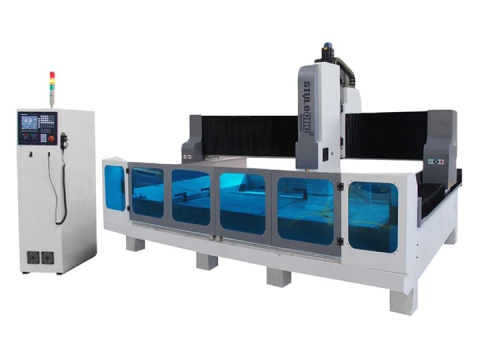

4x8 ATC CNC Router with Automatic Tool Changer Kit for Sale

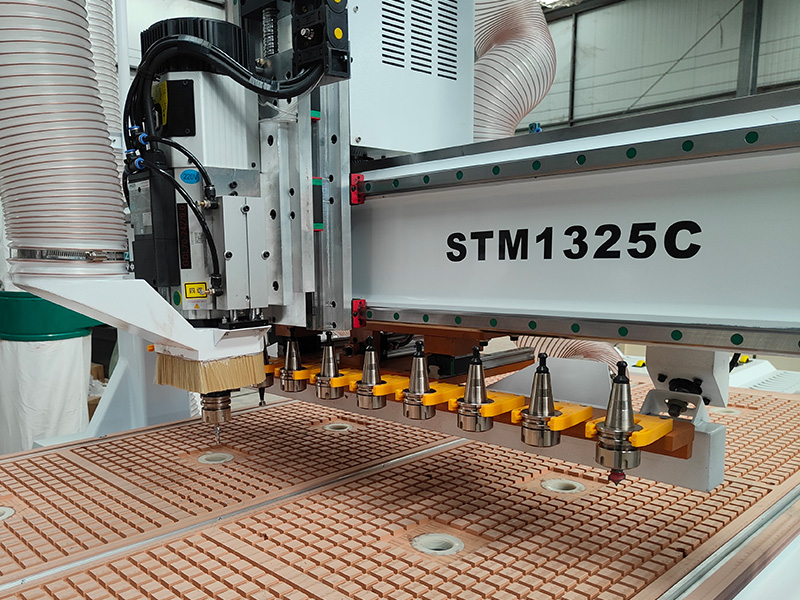

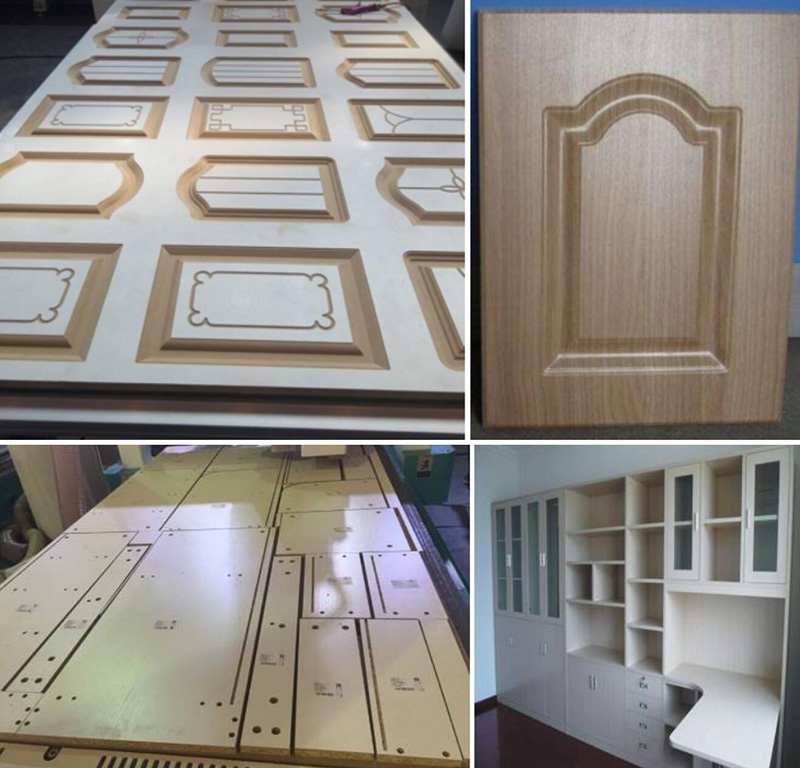

The best 4x8 ATC CNC router machine features linear automatic tool changer kit with a tool magazine of 12 router bits, which can be quickly and automatically changed to reduce downtime, thereby speeding up overall production cycle in industrial manufacturing. The full-size 4x8 CNC router table with ATC spindle kit is ideal for making complex parts that require a variety of tools and processes, such as cutting, milling, carving, drilling, slotting and tapping, making it popular in the manufacture of cabinets, wooden doors, decorative items, signs, crafts, artworks and more modern woodworking projects. In 2025, you can get such a professional 4' x 8' CNC woodworking machine that offers great value for money for just $13,300.

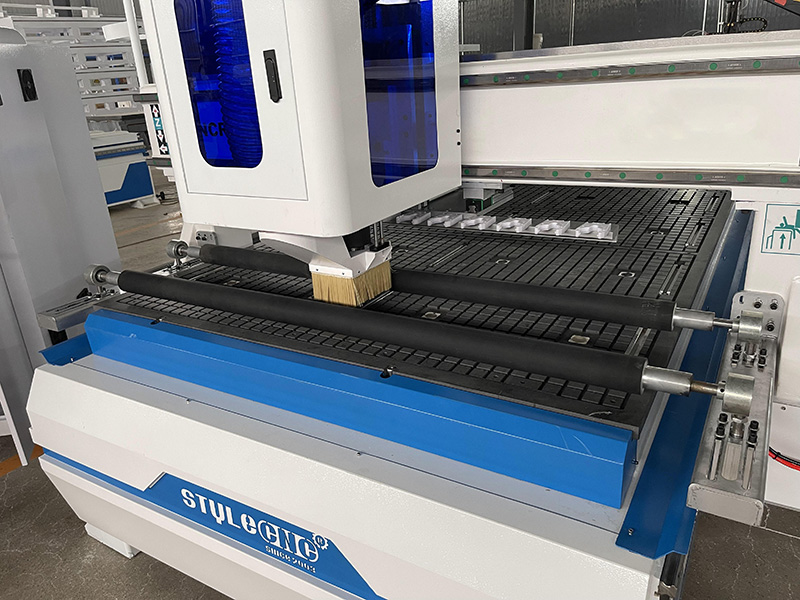

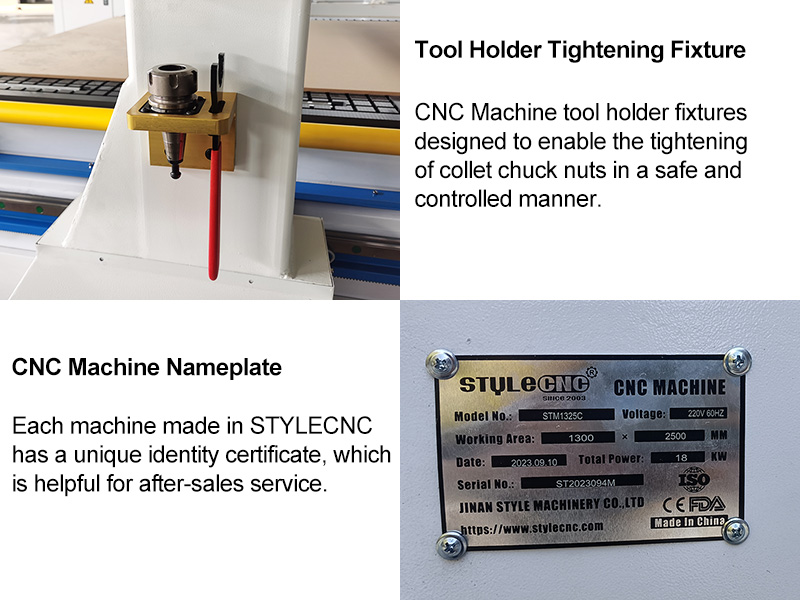

- Brand - STYLECNC

- Model - STM1325C

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

ATC CNC router is a kind of smart CNC machine with an automatic tool changer spindle kit. It is also called an Automatic Tool Changer, and the common ATC spindle usually carries 6 cutters, 8 cutters, 10 cutters, or 12 cutters. When working with the CNC router, the tool can switch automatically according to the demand of work, and no person is needed in operation, thus having excellent performance at its starting and great torque may exploit the advantage of its high speed, enabling a high-efficiency functioning. It applies the high-power servo motor that possesses all characteristics of low noise, great speed, and precision in position.

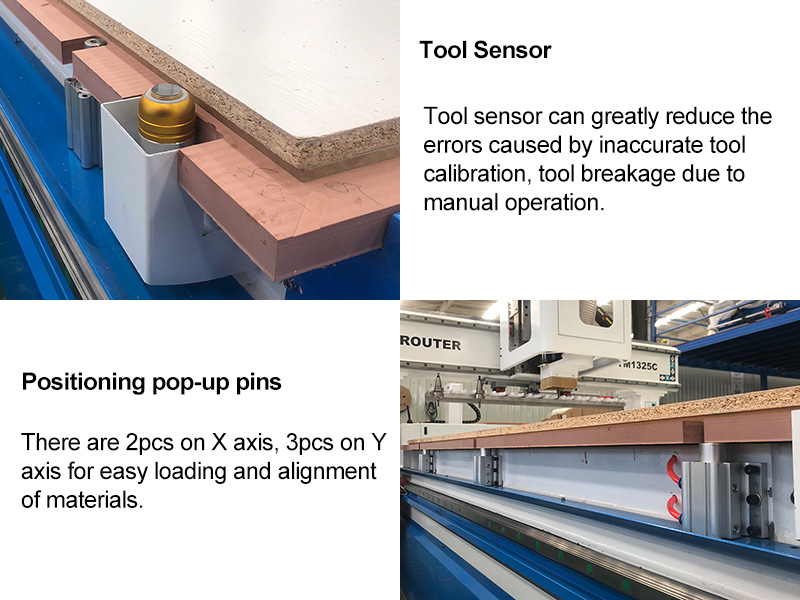

Equipped with a unique tool-changing mechanism, you can exchange the required tools at will, and the dedicated tool setting table can accurately compensate for the tool length error. The tool change time only takes a few seconds, which will improve the working efficiency greatly. There are two most common types of ATC CNC machines, which include linear-type automatic tool changers and rotary-type automatic tool changers. The best ATC CNC router machine adopts a rotary 4th axis for 3D cutting and carving.

Features of 4x8 ATC CNC Router with Rotary Automatic Tool Changer Kit

1. Heavy-duty machine body.

2. 9.0KW HQD air cooling spindle.

3. Automatic Tool Changer spindle with tools magazine of 12 cutters.

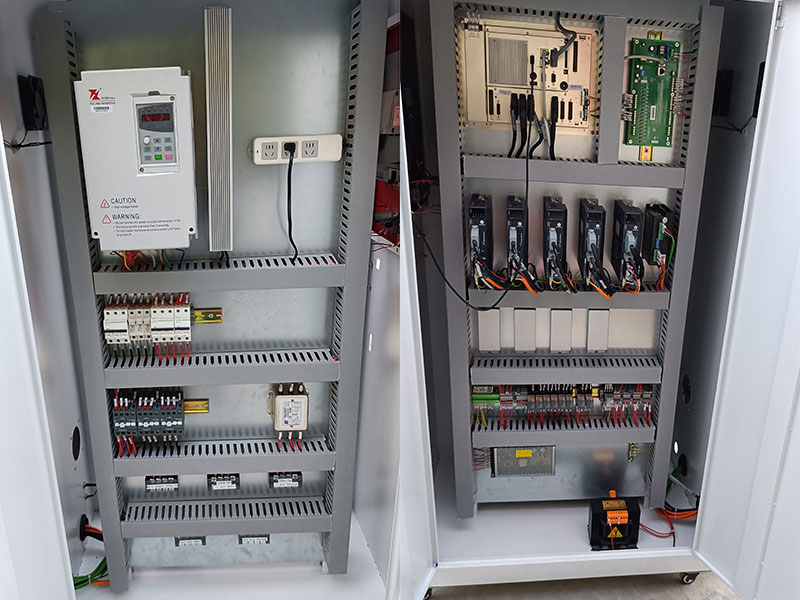

4. Taiwan LNC controlling system.

5. China large torque 1500W servo motor and drivers.

6. 11KW Fuling inverter.

7. Taiwan HIWIN 30 square rails.

8. Japan Omron limited switch.

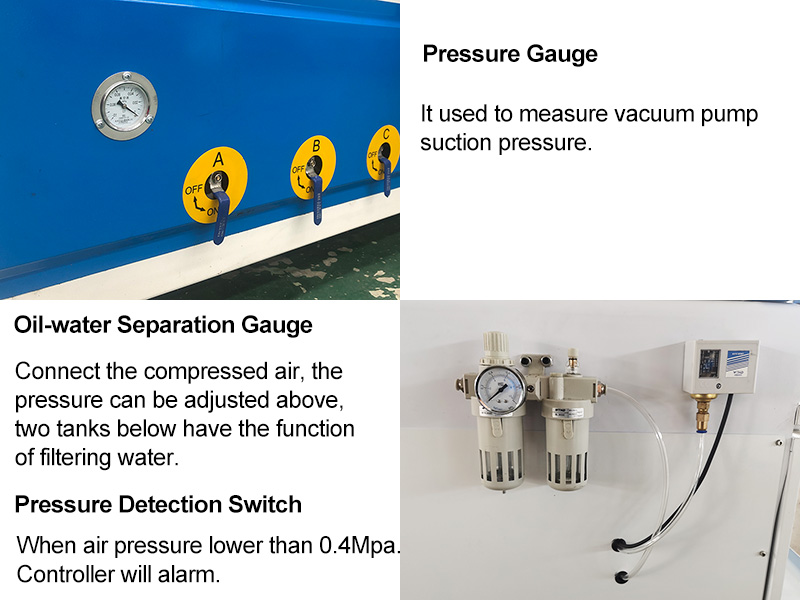

9. Strong suction dry vacuum pump 7.5KW.

10. Tool sensor.

11. Auto oil lubrication.

12. 4th rotary axis for 3D carving for option.

Technical Parameters of 4x8 ATC CNC Router with Rotary Automatic Tool Changer Kit

| Model | STM1325C |

| Table size | 1300mmX2500mmX300mm |

| Repositioning resolution | ±0.02mm |

| Max running speed | 50m/min |

| Max cutting speed | 30m/min |

| Tool magazine | Linear Type 12 tools |

| Working voltage | 380V/3 Phase/50HZ or 220V/3 Phase/Single phase/60HZ |

| Spindle | 9.0KW HQD air cooling |

| Spindle speed | 24000r/min |

| Driving system | Leadshine servo motor and drivers 1500W |

| Software | Artcam |

Optional Items for 4x8 CNC Router Machine with Linear ATC Spindle

| Spindle | 9.0KW HSD HSK-F63/ISO30 |

| Table Design | Vacuum&T-slot table combined |

| Vacuum Pump | 2.2KW with single phase |

| Hold Down System | Pressure rollers follow with the spindle for a hold-down on the workpiece. |

| Driving System | Yaskawa servo motors |

| Operation System | Syntec, Weihong, and more |

| Pneumatic drill | 5+4 drilling bank |

| Tool magazine | Disc tool changer 12 tools |

| Protection Device | laser light curtain |

| Automatic discharge | Automated loading and uploading system |

Details of 4x8 CNC Router with Linear ATC (Automatic Tool Changer)

Large double-door electrical cabinet with strong and weak current separation for 4x8 ATC CNC Router with Rotary Automatic Tool Changer Kit.

Automatic oil lubrication for the rails, keeps the machine running for in longer time.

4x8 ATC CNC Router comes with enough accessories when shipped.

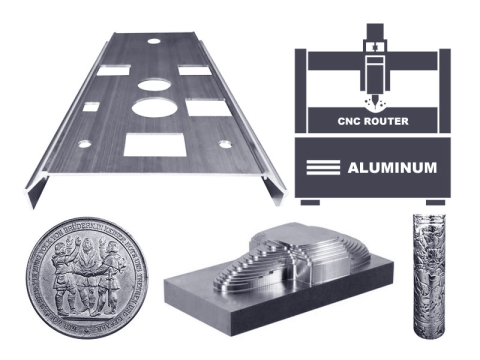

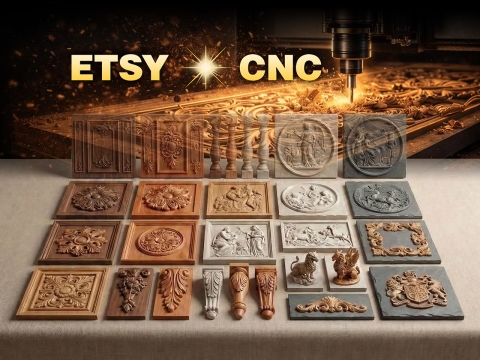

4x8 ATC CNC Router Machine Applications

1. Woodworking Industry: Stereo wave board processing, wooden doors, cabinet making, and other furniture production.

2. Advertising Industry: Label making, PVC plate, PCB board (drilling and engraving), double color boards, logo production, acrylic cutting, plastic suction for making advertising dedication, word cutting, sign making, crystal word, LED display screen, doorplate, nameplate, etc.

3. Mold Industry: Wood mold, foam mold, and metal mold, etc.

4. Musical instrument industry: Instrument 3D surface carving, shape cutting

5. Woodcrafts.

6. Exhibition industry: Showcase.

Benefits of Using a 4x8 ATC CNC Router for Woodworking and Metalworking

A 4x8 ATC CNC router provides the best efficiency, precision, and versatility for both woodworking and metalworking. Whether a furniture maker, signage manufacturer, or metal fabricator, one can easily find a huge boost in productivity with reduced human effort through the use of a 4x8 ATC CNC router.

Increased Productivity with Automatic Tool Changes

The ATC system allows the machine to switch between multiple tools automatically during operation. This eliminates the need for manual tool changes, saving time and reducing errors. Complex designs that require various tools can be completed in a single setup.

Precision and Consistency

Equipped with advanced motion systems and high-quality spindles, these routers deliver precise cuts and engravings. This consistency ensures that every piece produced meets exact specifications, reducing material waste and ensuring professional results.

Versatility for Various Materials

A 4x8 ATC CNC router can handle a range of materials, including hardwood, plywood, aluminum, and softer metals. This versatility makes it suitable for diverse applications such as furniture production, cabinetry, metal signage, and decorative items.

Large Working Area

The 4x8 worktable provides ample space for large-scale projects, allowing you to process full-size sheets of material without the need for resizing or additional setups. This is particularly useful for projects like doors, panels, and custom metal designs.

Cost-Efficiency in the Long Run

Although the initial investment may seem high, the efficiency, precision, and reduced labor costs make it a cost-effective solution over time. By automating repetitive tasks, it frees up skilled labor for more creative and high-value work.

Option Item Details for 4x8 ATC CNC Router Machine

Pressure rollers following with spindle for a hold-down on the workpiece:

Rotary Axis for Automatic Tool Changer CNC Router 3D Woodworking:

Vertical workstation for Automatic Tool Changer CNC Router 3D Woodworking:

Projects of 4x8 ATC CNC Router with Automatic Tool Changer Kit

Packages of 4x8 ATC CNC Machine with Linear Type Automatic Tool Changer Kit

1. Standard plywood case, its compressive strength, and bearing quality are better.

2. The boarding area is a bit, the soil structure is good, and it is better in leakproofness and waterproof.

3. When importing, the plywood case is fumigation-free, the procedure is simple.

Maintenance Tips for Keeping Your 4x8 ATC CNC Router Running Smoothly

Proper maintenance of the 4x8 ATC CNC router ensures constant performance, accuracy, and reliability. A regular preventive maintenance routine prevents costly breakdowns and keeps your equipment running at its best. Here's some practical advice on how to service your CNC router effectively.

• Clean the Machine After Each Use: Clear dust, debris, and leftover material from the worktable, spindle, and tool holder after every use. This will prevent buildups, which may affect machine performance over time.

• Regularly Lubricate Moving Parts: Apply recommended lubricants to linear guides, bearings, and ball screws weekly for smooth operations that minimize wear on important components.

• Check and Replace Worn Tools: Inspect cutting tools and bits for wear and tear. Replace dull or damaged tools promptly to maintain precision and avoid material damage.

• Monitor the Cooling System: Ensure the cooling system for the spindle operates efficiently. Replace coolant or water regularly, and in colder climates, consider using antifreeze to prevent freezing.

• Inspection and Adjustment of Belts: Check for belt tensions and adjust when needed. Too loose or too tight belts will affect the accuracy of the cut and put additional stress on the motor.

• Software and Firmware Updates: Keep the control software and firmware updated. Often, manufacturers release updates that help in enhancing machine performance and bug fixes.

• Insuring Electrical Connections: Check regularly that all electrical connections are secure and without any damage. Poor connections may lead to malfunctioning or failure of the machine.

• Run Diagnostics: Run periodic tests to diagnose any possible issues. Early detection may help avoid costly repairs.

STYLECNC Service for 4x8 CNC Router with ATC System

1. In the processing of production, our professional technical engineers inspect the processing to ensure the quality of products.

2. Every ATC CNC machine must be tested before delivery for 8 hours, all of them are qualified.

3. 24-month guarantee of the whole machine.

4. Main parts (excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

5. Lifetime maintenance free of charge.

6. We will provide the consumable parts at an agency price when you need replacement.

7. The ATC CNC machine has been adjusted before delivery.

8. Our staff can be sent to your company to install or adjust if necessary.

According to your requirements, we will recommend the best ATC CNC Routers for you:

1. What is your max working area?

2. What materials do you work on?

3. Do you mainly use the CNC router with ATC for carving or cutting? If cutting, What is the Max cutting thickness?

4. You can also send your product samples to us.

Similar ATC CNC Router Machines for Option

Linear Type ATC CNC Router with 4th Rotary Axis

ATC CNC Router with Dual Rotary Tools Magazine

Linear ATC CNC Router Machine for solid door

5x10 ATC CNC Router with Linear Automatic Tool Changer for Option (STM1530C)

Борзов

Sean Hemming

Ryan Stein

I purchased this CNC after researching how an automatic tool changer works in advance. Easy to put together with the instructions that came with it. Contacted STYLECNC and within a few minutes I got response on software installation and setting. Great customer service. I am using the software it came with since it works well for my business. This is a great machine for someone looking to get into automated woodworking and personalized furniture making.

Asa Uribe

Hilliard

Ethan

Alexandria

Mark Harris

I really have to say, this CNC router with tool changer is a great idea for my works, it worked well for cutting, carving, grooving in the past 3 months, it can complete a full door making process at one time, in addition, the rotary device can help me to do some 3D milling works.