I've wanted a laser cutter for a long time and finally got one when it went on sale with STYLECNC China National Day Deals. I was thrilled to finally receive it today after a 10-day wait. Everything was as expected. Out of the box and together without any issues. Easy to set up and operate for a beginner like me. My first cut was through 1/8-inch-thick plywood for an alphabet puzzle, working like a hot knife through butter, saving a lot of time compared to using a scroll saw. It took practice to learn the cutting thickness, speed, and power settings, but now I'm looking forward to using it for other jigsaw puzzles. All in all, it's perfect for my DIY jigsaw business. I really wish I had bought this STJ1390 years ago.

Chinese CO2 Laser Engraving Cutting Machines for Every Budget

Looking for a cheap and practical laser machine to cut or engrave wood, acrylic, plastic, stone, leather, fabric, paper? Don’t miss these affordable carbon dioxide laser engraver cutting machines made in China. They are popular all over the world for their low price and high performance. They are used in small businesses and commercial applications. You can find Chinese CO2 laser machines in homes and offices. Whether you are a business owner or an industrial manufacturer, owning a Chinese-made CO2 laser machine is a good option to make money and profit. It is easy to use, cost-effective, user-friendly, environmentally friendly, and low-cost. Beginners should buy it to get started, professionals should use it to upgrade their business, and schools should get it for teaching, training and research. Here are STYLECNC’s picks of the top-rated Chinese CO2 laser cutter engraving machines of 2023 for every budget and need. You don’t need to do much research, just compare features and costs to find the right machine for your business. Don't wait any longer, let's take a step forward.

2026 Best CO2 Laser Cutter for Small Business and Home Use

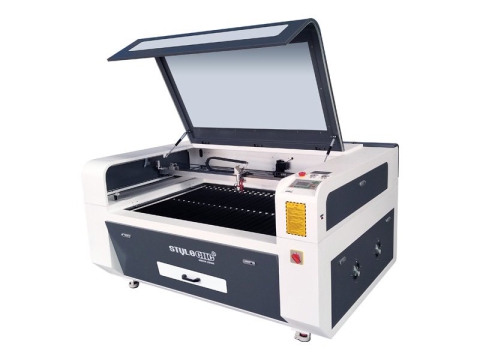

Entry Level CO2 Hobby Laser Cutter Machine for Beginners

100W Laser Wood Cutter Engraving Machine for Woodworking

2025 Best Acrylic Laser Cutting Machine for Sale

2025 Best Industrial Fabric Laser Cutting Machine for Sale

2025 Best Industrial Laser Foam Cutting Machine for Sale

Cheap CO2 Laser Engraver 60W, 80W, 100W, 130W, 150W, 180W

2026 Best CO2 Laser Engraver with Rotary Attachment

2025 Best Entry Level Small Laser Engraver for Beginners

Mini Desktop Laser Cutter Engraving Machine for Sale

2025 Top Rated Laser Wood Engraving Machine for Sale

Affordable Laser Engraver for Leather, Fabric, Paper, Jeans

CO2 Laser Marking Machine for Glass, Acrylic, Plastic

Affordable CO2 Laser Fruit Marking Machine for Coconut

Low Cost CO2 Laser Marking Machine for Leather & Fabric

2025 Best CO2 Laser Wood Marking Machine for MDF & Plywood

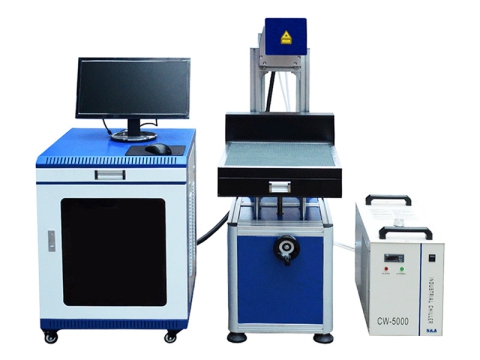

CO2 RF Laser Marking Machine with 30W Synrad Laser Tube

3D CO2 Laser Marking Machine for Paper Card Making

Things To Consider When Buying Chinese CO2 Lasers In 2025

Chinese CO2 laser machine is a cheap laser system that uses carbon dioxide laser beam to engrave, mark and cut for industrial manufacturing, school teaching & training, small business, home store, craftsman and hobbyists. It uses a carbon dioxide laser generator as the main processing emission principle. It uses carbon dioxide gas as the main gas processing core. With nitrogen and other gases as the core. The wavelength of its laser is roughly 10.6 microns. The stable performance is better, and the energy conversion can reach 25%. Light-transmitting gas with high energy rate can be achieved.

CO2 Laser Engraver

Chinese CO2 laser engraver is an automatic engraving system made in China that uses a 10.6 μm wavelength carbon dioxide laser beam to act on the surface of the substrate to vaporize the excess material to form pits, so as to make an engraved project. It is a carbon dioxide gas laser engraving cutting machine that uses the computer to control the X-Y console to drive the engraving head to move and control the switch as required. The CAD/CAM software generates a file from the designed pattern or text and stores it in the computer. When the machine reads the file from the computer, the head will move back and forth line by line from left to right and top to bottom along the scanning track, so as to finish the engraving job. It can ablate and cut wood, plywood, MDF, bamboo, paper, plastic, leather, cloth, glass, ceramic, resin, plastic, PCB, and stone.

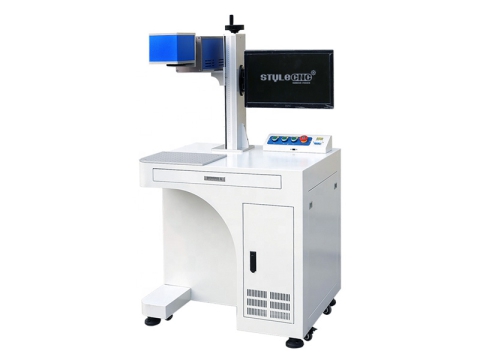

CO2 Laser Marker

Chinese CO2 laser marking machine is an automatic engraving tool made in China that uses a gas laser generator with a wavelength of 10.64μm, which uses the high-energy beam released by carbon dioxide gas molecules to engrave photo, pattern, text, or line on wood, paper, ABS, PVC, resin, acrylic, leather, glass, ceramic, and rubber. It is equipped with a high-speed scanning galvanometer and a high-precision beam expander focusing system for fine marking. Carbon dioxide laser marking is realized by using the thermal effect of the laser on the material. Or by heating and vaporizing the surface material to expose the deep layer of different colors. Or by heating the surface of the material with laser energy, it will undergo microscopic physical changes, so that its reflective properties will change significantly. Or some chemical reactions that occur when heated by laser energy, displaying etched graphics and text information. With a conveyor belt, it can mark on the fly, with a rotary attachment, it can engrave a cylinder, and with an XY moving table, it can achieve automatic segmentation and etching of large areas.

CO2 Laser Cutter

Chinese CO2 laser cutting machine is a professional automatic cutter made in China that uses a 1064μm laser beam to etch and cut wood, MDF, plywood, paper, leather, fabric, textile, resin, plastic, acrylic, rubber, crystal, glass, ceramics, stone, and more non-metallic materials. It relies on the power to drive the carbon dioxide gas laser tube to emit beam, with reflectors, the light beam is transmitted to the cutting head, and then the focusing mirror converges the beam on a point, and this point can reach a very high temperature, thus the excess material is instantly sublimated into gas, which is sucked away by the exhaust fan, so as to create a cut. CO2 laser cutters are used to engrave patterns and cut shapes & contours in clothing, fashion, garment, shoes, bags, toys, embroidery, electronic appliances, molds, models, arts, crafts, advertising, decorations, packaging, and printing.

Applications

CO2 laser machines are used for engraving, marking and cutting for wood, acrylic, leather, fabric, paper, foam, glass, metals of steel, alloy, aluminum, copper, silver and gold.

Types

CO2 laser machines come into cutters, engravers and markers depending on various functions. According to the laser generator, you will meet glass tube and metal tube laser machines.

Technical Parameters

| Brand | STYLECNC |

| Laser Power | 30 Watts - 300 Watts |

| Laser Type | CO2 laser |

| Laser Function | Cutting, Engraving, Marking |

| Price Range | $2,400.00 - $70,000.00 |

Buying Guide

Step 1. Consult:

We will recommend the most suitable CNC laser machine to you after being informed by your requirements.

Step 2. Quotation:

We will offer you with our detail quotation according to the consulted laser engraving and cutting machine.

Step 3. Process Evaluation:

Both sides carefully evaluate and discuss all the details of the order to exclude any misunderstanding.

Step 4. Placing an order:

If you have no doubts, we will send the PI (Proforma Invoice) to you, and then we will sign a contract with you.

Step 5. Production:

We will arrange the machine production as soon as receiving your signed sales contract and deposit . The latest news about production will be updated and informed to the buyer during the production.

Step 6. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete laser engraving and cutting machine will be tested to make sure they can work very well before out of factory.

Step 7. Delivery:

We will arrange the delivery as the terms in the contract after the confirmation by the buyer.

Step 8. Custom Clearance:

We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

Step 9. Support and Service:

We will offer professional technical support and free service by Phone, Email, Skype, WhatsApp, Online Live Chat, Remote Service. We also have door-to-door service in some areas.

What Our Customers Say?

Don't take our words as everything. Find out what customers say about our CO2 laser machines they have owned or experienced. Why is STYLECNC considered a credible brand and manufacturer to buy a new CO2 laser machine? We can talk all day about our quality products, 24/7 excellent customer service and support, as well our 30-day return and refund policy. But wouldn't it be more helpful and relevant for newbies and professionals alike to hear real-life customers experience what it's like to purchase and operate an automatic computer-controlled machine tool from us? We think so too, which is why we've collected tons of genuine feedback to help bring transparency to our unique buying process in-depth. STYLECNC guarantees that all customer reviews are real evaluations from those who have purchased and used our products or services.