Stone carving has evolved from ancient hand-chiseling techniques to sophisticated computer-controlled automation. Today's CNC stone carving machines represent the pinnacle of this evolution, delivering precision, speed, and versatility that manual methods simply cannot match.

Whether you're producing memorial headstones, architectural elements, or decorative art pieces, understanding stone carving machine applications helps you make informed decisions about equipment investments. In this comprehensive guide, STYLECNC explores everything from basic definitions to advanced applications and emerging market trends.

What Is a Stone Carving Machine?

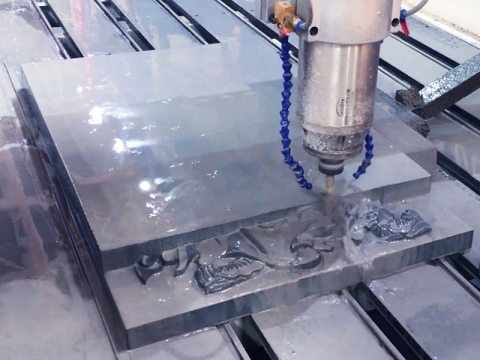

A stone carving machine is a high-tech, fully automatic computer-controlled system designed to carve, engrave, and cut patterns into hard materials. These machines use precision spindles equipped with diamond-tipped or carbide tools to remove material according to digital designs, transforming raw stone slabs into finished artistic or functional pieces.

Modern stone CNC machine centers can engrave intricate calligraphy, detailed portraits, complex relief sculptures, and geometric patterns on natural stone, ceramics, glass, and similar materials. The technology bridges the gap between artistic vision and mass production, enabling businesses to deliver personalized products at scale.

At STYLECNC, we manufacture stone carving equipment that serves diverse industries including monument makers, interior designers, construction companies, and artisan workshops. Our machines range from compact desktop 6090 stone CNC carving machines for small businesses to industrial 5-axis CNC stone cutting bridge saws for large-scale fabrication facilities.

Key Features of Modern Stone Carving Machines

Precision Motion Systems

Quality stone carving machines employ square linear guide rails with double-row or four-row sliding blocks. This configuration provides exceptional bearing capacity, enabling the machine to handle the substantial forces involved in cutting hard materials while maintaining positional accuracy measured in hundredths of a millimeter.

High-Performance Spindles

Constant power spindle motors deliver consistent cutting force regardless of load variations. This ensures uniform engraving depth and clean edges whether you're cutting soft limestone or hard granite. STYLECNC's stone cutting and polishing machines feature spindles specifically engineered for stone processing demands.

Software Compatibility

Professional stone carving machines support industry-standard CAD/CAM software including Type3, ArtCAM, and Castmate. This compatibility allows designers to create artwork in familiar environments and seamlessly transfer designs to the machine. The learning curve remains manageable even for operators transitioning from manual methods.

Advanced Tool Management

Modern systems include comprehensive engraving toolkits, relief carving functions, and bidirectional tool cooling systems. Water cooling prevents overheating during extended operations and flushes away stone dust that could otherwise damage precision components. Linear ATC stone CNC carving machines automatically change tools during complex jobs, eliminating manual intervention.

Intelligent Control Systems

CNC digital controls with breakpoint memory functions ensure work continuity even after power interruptions or emergency stops. The machine remembers exactly where it stopped and resumes from that precise position, preventing wasted material and time. Built-in timer processing features allow operators to estimate job completion times before starting, facilitating better scheduling and resource allocation.

Stone Carving Functions and Techniques

Stone carving machines perform multiple processing operations that previously required different specialized tools or highly skilled artisans.

Stone Lettering: Precise character engraving for monuments, signage, and commemorative plaques. The machine reproduces fonts exactly as designed, from traditional serif styles to contemporary scripts.

Stone Relief Carving: Creating raised designs that project from the background surface. 3D CNC stone carving machines excel at producing dimensional artwork including portraits, landscapes, and decorative motifs.

Positive Carving (Yang Carving): Material removal around design elements, leaving raised patterns. This technique creates bold, tactile surfaces ideal for architectural features.

Inverse Carving (Yin Carving): Cutting into the stone surface to create recessed designs. Commonly used for text and detailed imagery where shadow definition enhances visibility.

Line Carving: Fine linear engravings for detailed illustrations, technical diagrams, or delicate decorative patterns.

Stone Cutting: Profiling and shaping stone pieces to specified dimensions and contours.

Stone Hollowing: Creating openwork patterns and perforations for decorative screens, ventilation grilles, and artistic installations.

STYLECNC's stone CNC router projects showcase the remarkable range of techniques our equipment enables, from simple flat engravings to complex three-dimensional sculptures.

Primary Application Fields

Monument and Memorial Industry

The memorial sector represents one of the largest markets for stone carving equipment. Stone CNC machines for headstones, memorial stones, and tombstones produce personalized tributes with consistent quality and reasonable turnaround times.

Modern memorial fabrication often combines CNC router carving with laser photo engraving on granite and marble, creating detailed photographic reproductions alongside carved text and decorative elements.

Architectural and Construction

Interior designers and architects specify custom stone elements including wall panels, floor medallions, column capitals, fireplace surrounds, and decorative facades. Stone carving machines transform these designs into reality with precision that manual methods cannot economically achieve.

Stone CNC machining centers for wash basins and countertops demonstrate how these machines handle both artistic and functional applications within the construction industry.

Artistic Relief and Sculpture

Fine artists and commercial sculptors use 4-axis CNC stone carving machines for columns and Buddha statues to produce works that would require months of hand carving in mere days. The technology doesn't replace artistic vision but rather amplifies the artist's ability to realize complex concepts.

Advertising and Signage

Corporate logos, way finding signs, and promotional displays carved in stone project permanence and prestige. Stone carving machines enable sign companies to offer premium natural stone options alongside traditional materials.

Ceramic and Tile Industry

Beyond natural stone, these machines engrave patterns on ceramic tiles, porcelain, and engineered stone products. Customized tiles for feature walls, backsplashes, and flooring designs open profitable niche markets.

Handicraft Production

Artisan workshops producing jade jewelry, decorative objects, and gift items benefit from CNC jade carving machines that deliver consistent quality across production runs while preserving handcrafted aesthetic appeal.

Compatible Materials

Stone carving machines process an extensive range of materials beyond their namesake:

Natural Stones: Marble, granite, sandstone, limestone, slate, quartzite, gneiss, travertine, serpentine, and jade. Each material presents unique characteristics that experienced operators learn to accommodate through speed and feed adjustments.

Engineered Materials: Quartz composite, engineered stone, and sintered surfaces respond well to CNC processing with appropriate tooling.

Ceramics and Glass: Ceramic tiles, porcelain, glass panels, and plexiglass expand application possibilities into interior design and decorative arts.

Alternative Materials: PVC board, aluminum composite panels, bamboo, and hardwoods allow businesses to diversify offerings without additional equipment investments.

STYLECNC provides tapered diamond 3D deep relief bits for marble and granite and application-specific tooling recommendations for each material category.

How Stone Carving Machines Transform Business Operations?

The introduction of CNC stone carving technology fundamentally changes workshop economics and capabilities.

Dramatic Productivity Gains

Projects that previously demanded weeks of skilled labor now complete in hours. A detailed relief carving requiring 15 days of manual work might finish in under two hours on a properly configured CNC stone carving machine. This acceleration transforms project economics and enables businesses to accept work they previously couldn't profitably complete.

Reduced Labor Costs

While skilled operators remain essential for design, setup, and quality control, the physical carving work transfers to the machine. One operator can manage multiple machines simultaneously, multiplying effective capacity without proportional staffing increases.

Enhanced Precision and Consistency

CNC machines reproduce designs with identical precision across unlimited production quantities. Every piece matches the original design exactly, eliminating the variations inherent in manual production. This consistency proves especially valuable for architectural installations requiring matched sets.

Expanded Design Possibilities

Computer control enables complexity levels impossible to achieve manually. Intricate patterns, perfect geometric precision, and photographic detail reproduction become routine rather than exceptional.

Resource Optimization

Timer processing functions allow precise job duration estimates, enabling efficient scheduling and resource planning. Operators can start lengthy jobs with confidence, arranging other productive activities during machine operation.

Learn how to speed up your stone CNC router to maximize your productivity gains.

Market Trends and Future Outlook

The stone carving machine market continues to expand as technology advances and prices become more accessible.

Automation Integration: Increasing adoption of automatic tool changers, robotic loading systems, and production line integration streamlines high-volume operations.

Software Advancement: Improved CAD/CAM software with artificial intelligence assists designers in optimizing tool paths and predicting machining outcomes.

Hybrid Technologies: Combination systems integrating CNC routing with stone laser engraving capabilities expand single-machine versatility.

Accessibility Growth: Entry-level machines bring CNC stone carving within reach of small workshops and individual artisans, democratizing technology previously limited to large operations.

Historical replacement of manual stone carving with mechanized production represents an inevitable technological progression. Businesses investing in modern equipment position themselves competitively for long-term success.

Choosing the Right Stone Carving Machine

Selecting appropriate equipment requires matching machine capabilities to intended applications. Consider work envelope dimensions, spindle power, axis configurations, and software compatibility when evaluating options.

STYLECNC offers comprehensive consultation services to help customers identify optimal solutions. Our stone CNC router applications gallery and marble carving samples demonstrate real-world results across diverse applications.

Whether you need a compact desktop unit for occasional custom work or a full production CNC machining center for stone, STYLECNC provides equipment, training, and ongoing support to ensure your success.

Contact STYLECNC today to discuss your stone carving requirements and discover how our machines can transform your production capabilities.