The flow of the process used to make wood furniture has grown more important in recent years in order to produce durable, high-quality goods. Every stage of the procedure, from gathering raw materials to packing the finished good, is important. It is possible to produce furniture that satisfies industry standards and lasts longer by having a thorough understanding of each stage of the process. This article walks you step-by-step through the full process of making wood furniture, from logs to packaging.

Log

Log wood, the raw material hewn from trees, is where the journey of wood furniture starts. The entire process of making furniture starts with logs. After being harvested, the logs are sent to a sawmill and processed in order to be ready for further processing.

In order to guarantee that the wood is appropriate for additional processing, log preparation is necessary. At this point, variables such as the kind of tree, the size of the log, and the moisture level are taken into account. The logs are examined and sorted at the sawmill based on their type and quality. In this stage of production, careful handling avoids waste and harm to the wood later on. After the logs are prepared, the sawmilling procedure is the following stage.

Sawmilling Process

The sawmilling process is the first major step in furniture production. Logs are cut into smaller panels and blocks based on the required size. It is now easy to position the wood panels for drying because the type and thickness are known.

The wood is left outside to let moisture evaporate naturally before it is placed inside the kiln. To prepare wood for kiln drying, it should be exposed to outside temperatures for a minimum of one week.Proper sawmilling ensures smooth processing in later stages, as panels and blocks are arranged according to their size and type. This step ensures efficient drying and reduces the chance of wood damage.

Kiln Dry Process

The wood must be dried in a kiln in order to eliminate moisture. Reducing the moisture content to approximately 12–15% stops damage such as warping and cracking. It takes between two to four weeks for this process, depending on the type of wood, panel thickness, and size of drying space.

Both hardwood and softwood are guaranteed to be stabilized through proper kiln drying. Softwoods are particularly vulnerable to cracking when they dry out too soon. It is essential to use the proper tools for this process in order to preserve the wood's quality. A well-run kiln drying procedure reduces the possibility of deformed or fractured wood, guaranteeing the material is prepared for the following phase of production.

Splitting & Cutting Process

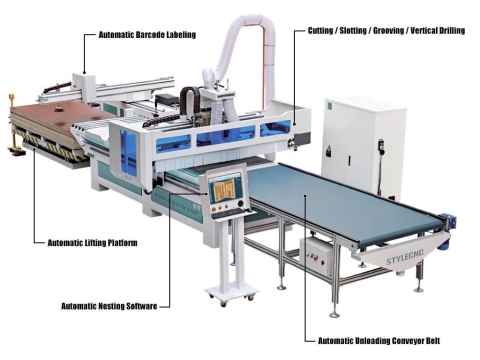

The splitting and cutting process is where the wood takes shape. Panels and blocks are cut into the specific sizes required for furniture production using CNC machines or saw cutters. Precise cutting ensures that the components fit together perfectly during assembly.

Accurate splitting and cutting are important for reducing waste and saving time in later steps. If the pieces are not cut correctly, they may not align during assembly, leading to defects or delays. CNC machines play a vital role in this stage by providing precision and efficiency. After this process, the cut components are ready for planing and drilling.

Planing & Drilling Process

In this step, small wooden blocks are sent through a planer machine to achieve a smooth, line-free surface. Proper planing ensures that the components are even and ready for further processing.

After planing, the components are drilled using tenoners and mortisers to create precise joints for construction. These tools are essential for ensuring the strength and stability of the furniture. Accurate drilling also ensures the components fit together properly during assembly. The final step before sanding is to inspect the pieces for defects to ensure they meet quality standards.

Sanding Process

Sanding is essential for smoothing out the surfaces of all components before assembly. It ensures the pieces are properly refined, with the correct dimensions and smooth finishes. This step also removes any small imperfections that may have been missed during planing and cutting.

Thorough sanding ensures a polished, finished product and facilitates the application of coatings later on. Additionally, furniture that has been properly sanded is more resilient to deterioration. The parts are prepared for assembly into completed goods after sanding.

Assembling Process

One of the most important phases in the manufacture of furniture is assembly. To form the finished product, the components must be joined. Certain pieces may need to be pre-assembled prior to final finishing, while other sections may be assembled after finishing, depending on the design.

To make sure that the components fit precisely, this method calls for patience and precision. Applying glue correctly is crucial to making sure the furniture is sturdy and solid. In order to preserve quality, any flaws or holes in the joints are fixed during this phase. Although assembly can take some time, it is essential to the product's robustness and longevity. The furniture goes to the finishing stage after assembly is finished.

Finishing Process

The furniture is given the finishing touch, which improves its beauty and guards against harm. To preserve the wood surface from moisture and insect damage, protective coatings are layered on top of it.

The type of furniture will determine whether finishing should be done before or after assembly. Proper application of the finish guarantees longer-lasting and aesthetically pleasing results. Customization is also possible with this procedure because different finishes can be utilized to achieve different styles. After completing, the product is prepared for packaging.

Packing Process

After finishing, the furniture moves to the packaging area, where it is prepared for shipment. Accessories like handles, keys, or wheels are attached if required. The packaging depends on the product’s quality and destination.

High-end furniture or products shipped to distant locations require strong packaging to prevent damage during transportation. Proper packing ensures the furniture reaches customers in perfect condition, maintaining the manufacturer’s reputation. With the product packed and ready, the furniture-making process is complete.