Before buying a laser cutter or during the use of a laser cutting machine, you may be wondering what materials can be laser cut? what materials are best for CO2 laser cutters? what materials are suitable for fiber laser cutting? STYLECNC helps you eliminate doubts, collecting 15 most popular laser-cuttable materials. Here is a complete list of the best laser cutting materials.

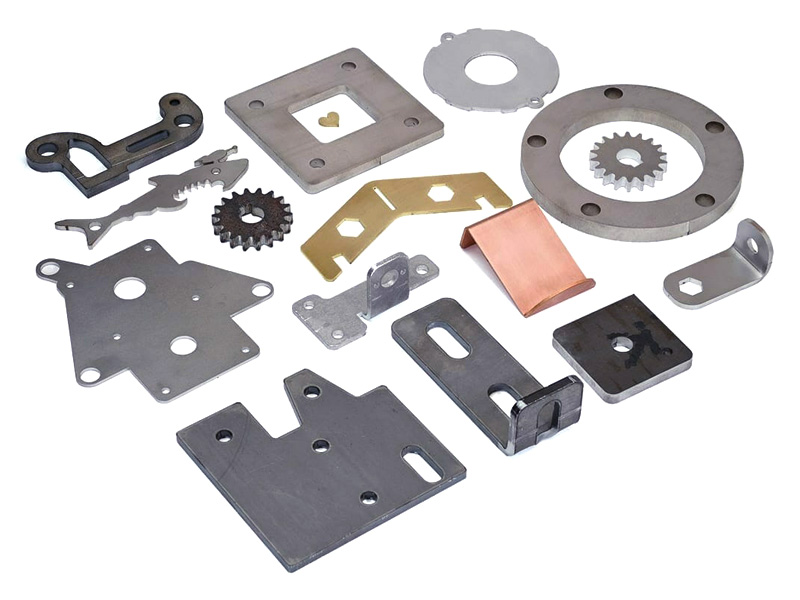

The Best Fiber Laser Cuttable Materials

What materials can fiber laser cut? As we all know, the initial absorption rate of metal for 10.6um laser beam is only 0.5%~10%. However, a focused laser beam with a power density exceeding 106w/cm2 can quickly start melting the surface in microseconds when it is irradiated onto the metal surface. The absorption rate of most metals in the molten state increases sharply, typically by 60% to 80%. In most cases, fiber lasers are typically used to cut the following most popular metal materials.

Carbon Steel

Carbon steel is the most popular material that can be cut with a fiber laser. The maximum thickness of high-power fiber laser cuttable carbon steel sheet can be up to 130mm. The slit of carbon steel can be controlled within a satisfactory width range by using the oxidation melting cutting mechanism, which is suitable for cutting thin carbon steel plates, and the seam can be as narrow as about 0.1mm.

Stainless Steel

Stainless steel is a versatile material for laser cutting, from advertising signage to automotive parts. The fiber laser machine is an efficient and high-precision cutting tool for manufacturers that use stainless steel sheets and tubes in metal fabrication. By strictly controlling the heat input during the cutting process, the heat-affected zone of the cutting edge can be limited to a small size, thereby effectively maintaining the good corrosion resistance of the stainless steel material.

Alloy Steel

Most alloy structural steels and alloy tool steels can be laser cut to get good edge quality. Even for some high-strength alloy steels, as long as the cut parameters are set appropriately, straight and slag-free cutting edges can be obtained. However, for high-speed tool steel and hot die steel containing tungsten, corrosion and slag sticking will occur during cutting.

Aluminum & Alloys

Aluminum is a highly reflective metal material that can be cut by laser. Although its absorption rate of laser is low, laser can cut aluminum and its alloys by melting, and use auxiliary gas to blow away the slag from the cutting area to get higher quality cuts. For some aluminum alloys, attention should be paid to preventing the occurrence of intergranular microcracks on the slit surface.

In addition, it is recommended to use nitrogen when laser cutting aluminum plates. Because of the special color of aluminum and to ensure uniform color of the cut products, nitrogen can prevent oxidation well and retain the characteristics of the material itself. Nitrogen is a better choice.

Copper & Brass

Fiber lasers emit at a wavelength of approximately 1.07 µm, while conventional CO2 alternatives emit at 10.6 µm. The 1.07 µm laser is less reflective and therefore easier to absorb, and the shorter wavelength can be focused into a spot that is approximately 1/10 the diameter of the CO2 beam, which provides great power density and makes metal cutting easier. At such high power density levels, metals such as copper and brass rapidly undergo a phase change into a molten state, and the laser beam quickly overcomes the reflectivity barrier of such metals, initiating an efficient cutting process.

Pure copper (red copper) and brass (copper alloy) require high laser power and auxiliary gas (nitrogen) to cut due to their high reflectivity.

Although CO2 laser can also cut copper, a layer of graphite spray or magnesium oxide must be coated on the copper sheet to prevent reflection from damaging the machine.

Titanium & Alloys

Pure titanium can well couple the heat energy converted by the focused laser beam. When oxygen is used as the auxiliary gas, the chemical reaction is intense and the cutting speed is faster. However, it is easy to form an oxide layer on the cutting edge, which may cause overburning if not careful. To be on the safe side, it is better to use air as the auxiliary gas to ensure cutting quality.

Nickel Alloy

Nickel-based alloys are also called super alloys, and there are many varieties, most of which can be oxidized and melted for cutting.

Silver & Gold

In addition, high-precision fiber laser cutters can also cut precious metals with high reflective properties such as gold and silver.

Most Popular CO2 Laser Cutting Materials

The CO2 laser cutter with a wavelength of 10.6um can cut wood, acrylic, plastic, foam, paper, leather, fabric, textile, plexiglass, epoxy resin, wool, rubber, ceramic tiles, crystal, jade, bamboo and other non-metallic materials.

CO2 lasers can cut through materials of varying thicknesses from paper as thin as less than 1 mm to foam thicker than 50 mm, and can also easily handle harder acrylic and solid wood, as well as softer leather and fabric.

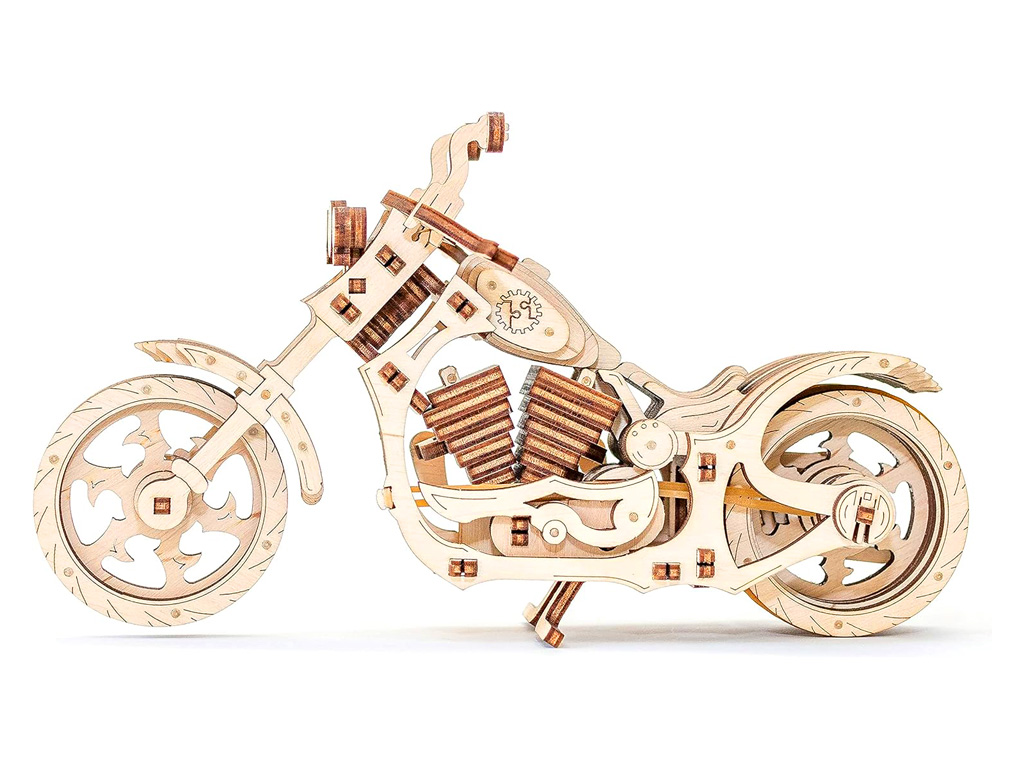

Wood

Wood is the the best material for laser cutting, including MDF, plywood, balsa, birch, poplar, red oak, cherry, holly, and more. The wood cuts by CO2 laser come with high precision, narrow cutting slit, fast speed and smooth cutting surface. However, because the laser focuses energy to melt the wood, there will be blackening during the cutting process, that is, the cutting edges are carbonized. When cutting wood, you must choose the right power, set the right parameters, and use a high-power air compressor, so that the wood cuts will not be blackening and yellowing.

In conclusion, CO2 laser cutters can cut through a variety of wood thicknesses from less than 1/4 inch to as much as 1 inch, depending on the laser power options and the hardness of the wood. Higher power can handle thicker wood. Softer wood tend to cut easier and deeper than plywood and harder wood.

Acrylic

CO2 lasers can easily cut acrylic (also known as Plexiglass, Lucite, PMMA) with a perfect flame polish effect without post-processing. The laser vaporizes the plastic, leaving a clean, sharp edge when cut.

Laser cutting is ideal for applications where appearance is important. Acrylic is available in a variety of colors and can be used for signage, point-of-sale displays, costume jewelry, trophies and awards, decorations, lighting, the creative possibilities are endless.

Plastic

Plastic is the mostly used laser cutting material. CO2 laser features with high absorption rate and low thermal conductivity. With industrial chiller, it can cut various plastic materials, including:

• ABS (Acrylonitrile butadiene styrene).

• Mylar (Polyester).

• Delrin (POM, acetal).

• Kapton tape (Polyimide).

• Nylon.

• Styrene.

• Polypropylene (PP).

• Polyethylene (PE).

• PETG (Polyethylene terephthalate glycol).

• High density polyethylene (HDPE).

Foam

Lasers are able to cut foam easily, allowing you to create 2D/3D cuts in minutes. Due to the fine cutting of the laser beam, it is not easy to deform, the incision is smooth and there is no blurred edge.

• EVA.

• EPM.

• Depron foam.

• Gator foam.

Leather & Fabric

CO2 lasers can easily cut most leather, fabric, suede, felt, hemp, cotton and textiles with CCD camera for automatic positioning, with auto feeder for automatic loading and unloading.

Paper

Lasers are capable of cutting a variety of paper materials, including kraft paper, kraft cardboard, paper bag paper, packaging paper, corrugated cardboard, offset paper, stone paper, copy paper, typing paper, cable paper, rice paper, thermal paper, carbonless paper, butter paper (sulfuric acid paper), insulating paper, Transparent paper, cellophane, silicone paper, release paper (anti-adhesive paper), laminated paper, boxboard paper, yarn tube paper, parchment paper, coated paper, composite paper.

Rubber

CO2 lasers come with the ability to cut most types of rubbers, including:

• Natural rubber - DL-limonene, isoprene.

• Vulcanized Rubber.

• Synthetic rubber - Chlorosulphonated polyethylene, neoprene rubber, silicones, nitrile rubber, nitrile butadiene rubber, ethylene (EPDM) rubber, styrene butadiene rubber butyl rubber, fluorosilicone rubber, polychloroprene, polyurethane rubber, polyacrylic rubber, polyflouroelastomer rubber, epichlorohydrin rubber.

The Best Materials for Hybrid Laser Cutting

A hybrid laser cutting machine can cut both metal and non-metal materials, as well as metalloids with air-cooled metal CO2 laser tube. However, only thin sheet metals can be cut through due to its lower power.

Conclusion

All in all, the best materials for laser cutting range from soft fabrics to hard metals, covering almost all raw materials, with the most popular ones being stainless steel, carbon steel, aluminum, brass and copper, as well as wood, plywood, acrylic, plastic, leather, paper, cardboard, foam, and rubber.