Fiber laser cutting machine with its various advantages gradually replace other processing methods, more and more widely used in sheet metal processing industry. Currently on the market, the small and medium-sized sheet metal processing enterprises use 1000 watts fiber laser cutting machine. 1000 Watts fiber laser cutting machine can cut the 4mm thickness stainless steel and 8mm carbon steel. So we discuss how to make 1000 Watts fiber laser cutting machine more efficiency and fast speed cutting on the basis of the guarantee of cutting thickness, so as to enhance the product added value.

After many years research and practical experience in the industry, STYLECNC engineers summed up the various factors as follows: laser cutting materials, assisted gas pressure, machine parts, cutting speed, and focus location.

6 Factors Impairing Laser Cutting Quality of Fiber Laser Cutting Machine

1. Laser output power and mode.

The higher the output power of the laser, the better the cutting quality on the plate of the same thickness. The higher the fit between the laser cutting mode and the material, the better the cutting quality.

2. Workpiece material.

The effect of fiber laser cutting machine on different materials is different. Different metal materials have different characteristics, and the absorption of laser heat is also different. Common materials such as stainless steel, carbon steel, and iron plates absorb heat quickly. The cutting quality is also high. On the contrary, high-reflective materials (aluminum, copper) are more difficult to cut.

3. The thickness and surface smoothness of the workpiece.

The metal fiber laser cutting machine is suitable for cutting thin plates. The cutting effect of carbon steel below 12mm and stainless steel below 6mm is obvious, the quality is the best, and the efficiency can be guaranteed. In addition, generally speaking, the smoother the surface of the material, the better the quality of the cut.

4. Selection of focus position.

It is very important for the fiber laser cutting machine to determine the corresponding position of the focus and the surface of the material before working, and it is directly related to the quality of the cutting. The power at the focal point is the highest, and most of the time the focal point is at the surface of the cutting material. When the focal point is in the best position, the minimum slitting, the highest efficiency, and the best cutting speed can achieve the best cutting. result.

5. Cutting speed.

The cutting speed has a very direct effect on the quality. Too fast a fiber laser cutting machine will easily cause the material to be impenetrable, and too slow will cause the residual cutting slag and the phenomenon of burning edges. Therefore, we must adjust the parameters according to the actual thickness calculation of the workpiece to try cutting to achieve the best cutting speed.

6. Pressure and type of auxiliary gas.

The pressure of the auxiliary gas also has a certain impact on the cutting quality. When using a laser cutting machine to cut some thin metal plates at high speed, generally higher gas pressure is required to prevent slagging on the back of the cut. If the thickness of the material increases or the cutting speed decreases, the auxiliary gas pressure should be lowered. At the same time, in order to prevent oxidation of the cutting edge, the appropriate gas pressure should be adjusted.

11 Benefits of Fiber Laser Cutting Machine

1. High cutting precision.

The positioning accuracy of the laser cutting machine is 0.05mm, and the repositioning accuracy is 0.03mm.

2. Narrow slit.

The laser beam is focused into a small spot, so that the focal point reaches a high power density, the material is quickly heated to the degree of vaporization, and evaporates to form a hole. With the relative linear movement of the light beam and the material, the hole continuously forms a slit with a very narrow width. The width of the slit is generally 0.10-0.20 mm.

3. Smooth cutting surface.

There is no burr on the cutting surface, and the surface roughness of the incision is generally controlled within Ra6.5.

4. Fast cutting speed.

The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, which is much faster than the wire cutting speed.

5. Good cutting quality.

Non-contact cutting, the cutting edge is little affected by heat, there is basically no thermal deformation of the workpiece, and the collapse of the material formed during punching and shearing is completely avoided. Generally, the cutting seam does not require secondary processing.

6. No damage to the workpiece.

The laser cutting head will not touch the surface of the material to ensure that it does not scratch the workpiece.

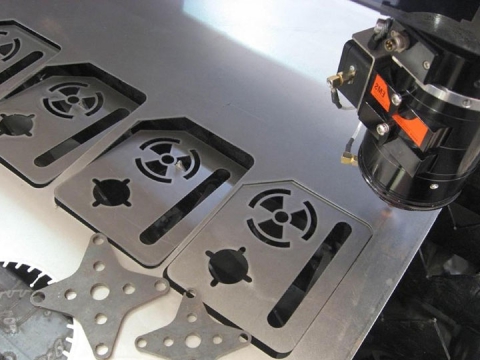

7. Not affected by the shape of the workpiece.

The laser processing has good flexibility, can process any graphics, and can cut pipes and other profiles.

8. Saving mold investment.

Laser processing does not require molds, consumes no molds, does not need to repair molds, and saves time for mold replacement, thereby saving processing costs and reducing production costs. It is especially suitable for processing large products.

9. Save materials.

Using computer programming, products of different shapes can be cut to maximize the utilization of materials.

10. Improve the speed of sample delivery.

After the product drawing is formed, laser processing can be performed immediately, and the physical object of the new product can be obtained in the shortest time.

11. Safety and environmental protection.

Laser processing has less waste, low noise, clean, safe, and pollution-free, which greatly improves the working environment.