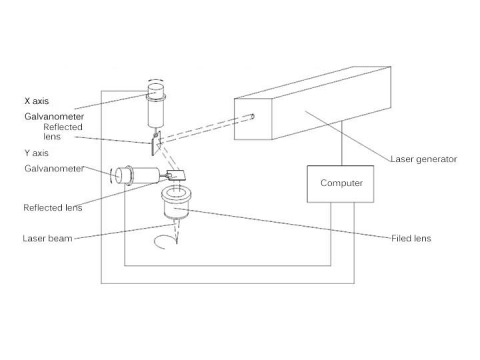

Laser cutting machine working princinple: laser generator generates laser beam, then transferred the laser beam to the laser cutting head through the optical path, then focus together into a high density energy, high energy foucs on the metal surface to be extremely high temperatures and instantly melt the metal, the assist gas blowing off the slag to form dicing lines, so as to achieve the cutting purpose. Fiber laser cutting machine with high precision, fast cutting, cutting pattern is not limited, automatic typesetting material savings, cut smooth, low processing costs, will gradually improve or replace the traditional metal cutting process equipment.

There are many different fiber laser cutting machines on the market. The laser cutting power from 500W to 100000W.

So why fiber laser cutting machine speed is not the same under normal circumstances? Let STYLECNC introduce for you.

1. 500W fiber laser cutting machine is suitable for cutting below 4mm plate, cutting speed can reach about 10m/min. (Take 1mm stainless steel as example).

2. 1000W fiber laser cutting machine is suitable for cutting max 10mm metal sheet, for thicker metal cutting, the speed is relatively slow and it will harm the laser source.

3. 2000W fiber laser cutting machine is popular in the market, because this device both in cutting speed or price can meet customer needs.

4. 3000W - 100000W is high power fiber laser cutting machine. Although fast enough, cutting quality is good enough, but the price is higher, not each factory can bear it.