Stone CNC Machining Center for Cutting and Polishing

Stone CNC machining center is suitable for cutting and polishing natural marbles, granites, quartz stones, blue stones, tombstones, headstones. Now the best automatic stone cutting & polishing machine for sale at affordable price.

- Brand - STYLECNC

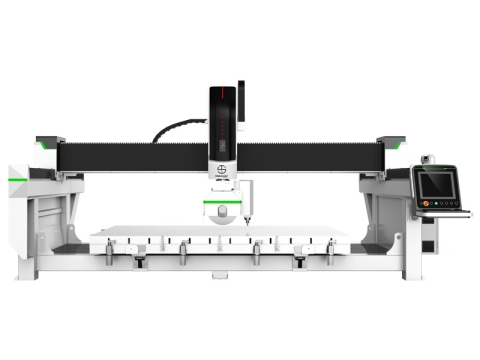

- Model - STS3113

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 1300mm x 3100mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

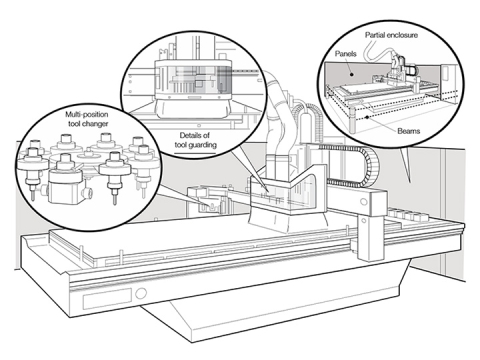

Features of Stone CNC Machining Center:

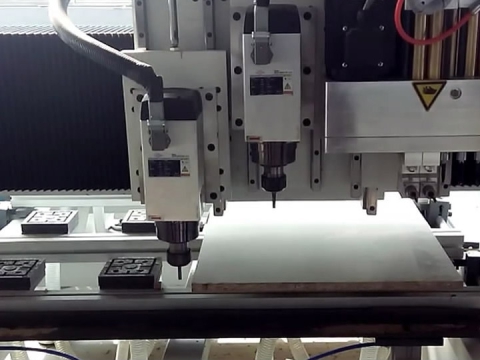

1. Vacuum adsorption table design, feeding is convenient and quick.

2. High-power spindle motor is more suitable for cutting.

3. The stone CNC machine is more stable, more durable, effectively reducing the equipment in high-speed operation, the spindle jitter, broken knife, dislocation and so on.

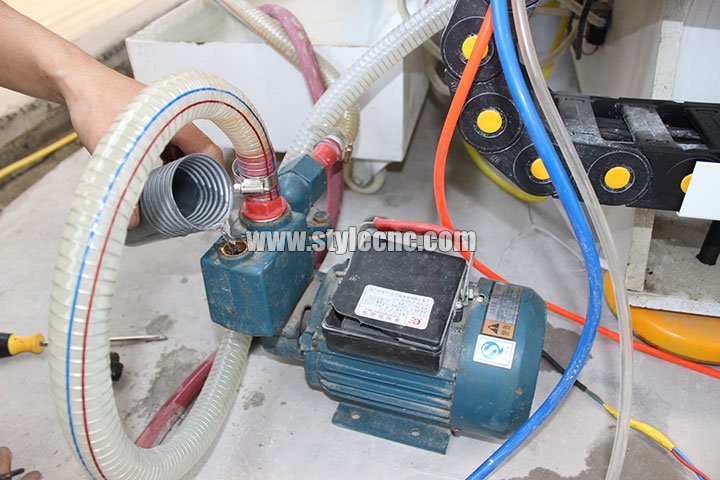

4. A unique filter tank, water circulation system, effectively extending the service life of the sink.

5. Automatic oiling system, maintenance and more convenient.

6. Three shaft all dustproof and waterproof design.

7. Top brand spindle to ensure that the stone CNC machine in the high-speed operation, the output torque capacity unchanged, the spindle wear, high temperature.

8. All institutions of the stone CNC machine are made of precision parts assembled.

Technical Parameters of Stone CNC Machining Center:

| Model | STS3113 |

| Working Area | 3100*1300*500mm |

| Lathe Bed | Thick steel weld |

| Table | Steel board+Aluminum board |

| Guide Rail | 35mm Taiwan Square Rail |

| X/Y Axis Transmission | Imported Rack Gears |

| Z Axis Transmission | Imported Ball Screw |

| Spindle | BT40 ATC 5.5 kw spindle |

| Spindle speed | 0-8000rmp/min |

| Running speed | 0-8000rmp/min |

| Feeding speed | 1-10000mm/min |

| Fast feeding speed | X/Y: 15000mm/min Z: 6000mm/min |

| Working accuracy | 0.05mm |

| Reposition accuracy | 0.02mm |

| Maximum processing thickness | 350mm |

| Motor | Japanese servo motor |

| Drive | Servo driver |

| Reducer | Brand from Taiwan |

| Way of fixing Workpiece | Scuction Cup |

| vacuum pump | 5.5kw water-cooling |

| ATC | 8 sets Vertical-type ATC system |

| Position | Air Cylinder |

| Control system | SYNTEC control system |

| Engraving Command | G code, PLT, HPGL2D, 3D |

| Software compatability | Origin UCANCAM software |

| Switch and emergency stop | The best one in China |

| Working voltage | AC380V/3phase,50HZ |

| Weight | 4000KG |

Applications of Stone CNC Machining Center:

Quartz stone cabinet countertops processing, stone side modeling, arc retaining water grinding, basin pots, stone relief, hollow, line carving.

Granite, marble, bluestone, tombstone, headstone and other stone materials processing.

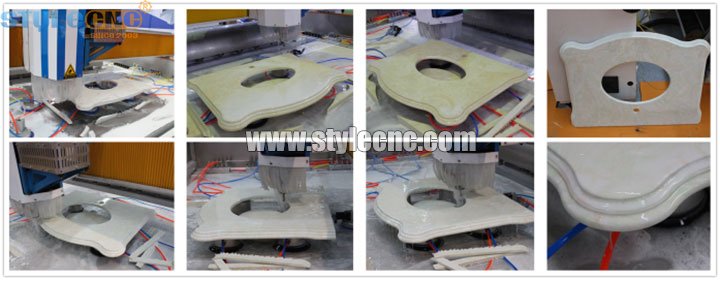

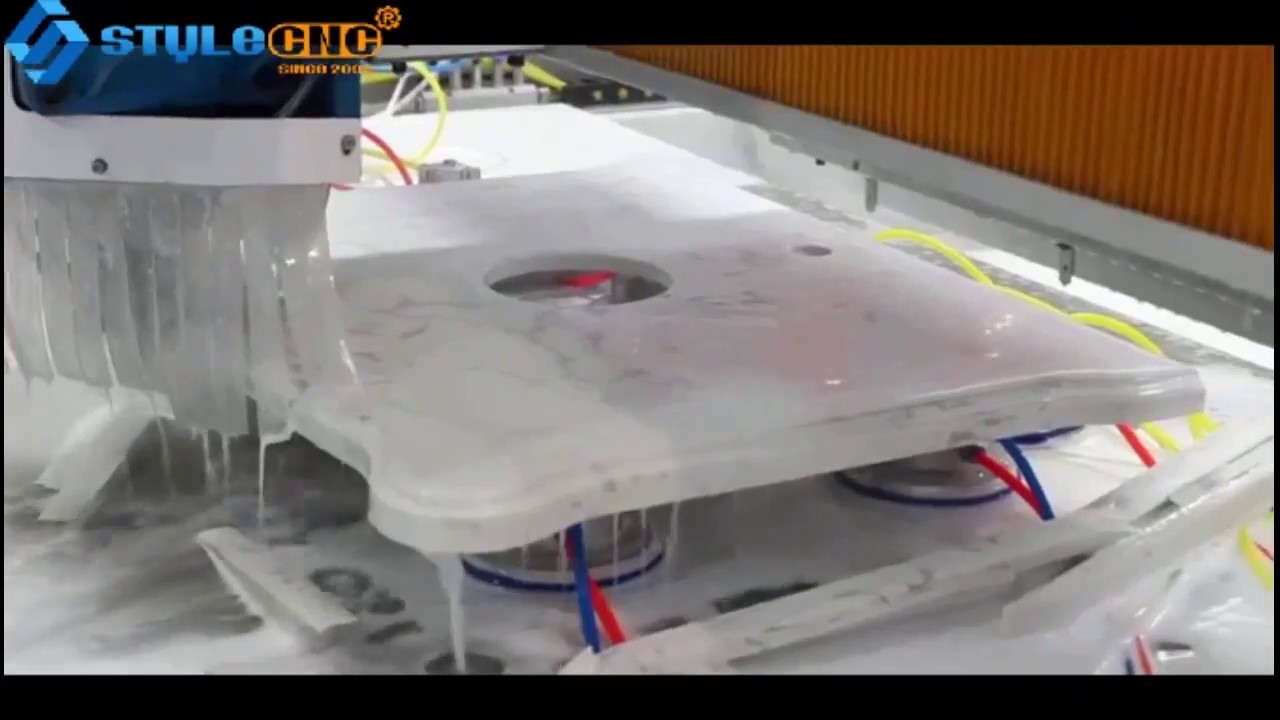

Detail Pictures of Stone CNC Machining Center:

Projects of Stone CNC Machining Center:

George

Pavel

Just received this large stone CNC machine. Engineers from STLECNC helped me for training and installation, which is very helpful for this machine. I am glad to have this unit and meet the lovely people from STYLECNC. Recommended.