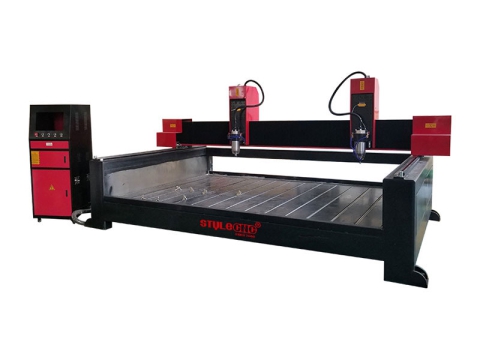

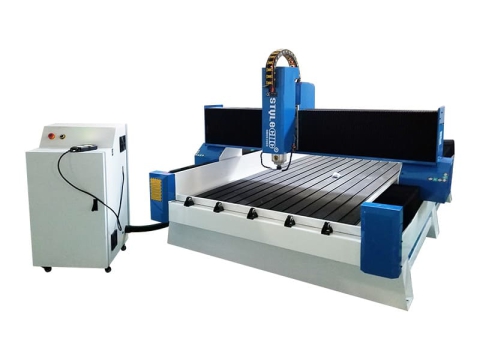

Automatic 4x8 Stone CNC Machine for Headstone & Tombstone

Automatic 4x8 stone CNC machine STS1325H is designed for headstone, memorial stone, granite tombstone with CNC bits for carving traditional v-sink letters, and laser head for memorial photos engraving.

- Brand - STYLECNC

- Model - STS1325H

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4' x 8' (48" x 96", 1300mm x 2500mm)

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

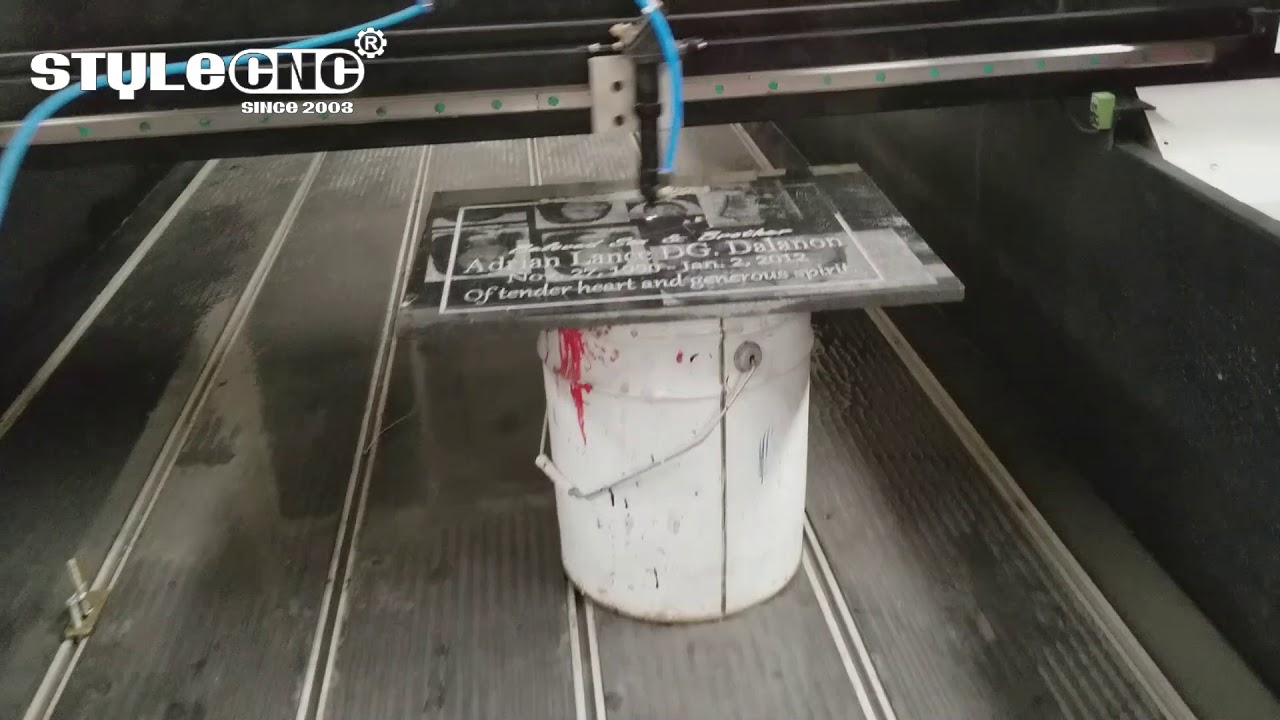

A 4x8 stone CNC automatic headstone and tombstone machine is a computerized cutting and engraving system used in the processing of large slabs of stone. It measures 4x8 feet and can be used to engrave stones of all sizes, making it appropriate for producing detailed memorial carvings, epitaphs, as well as other decorative designs in granite, marble, and other hard materials. The machine is faster and does not involve human error, unlike manual carving, and thus takes less time to make.

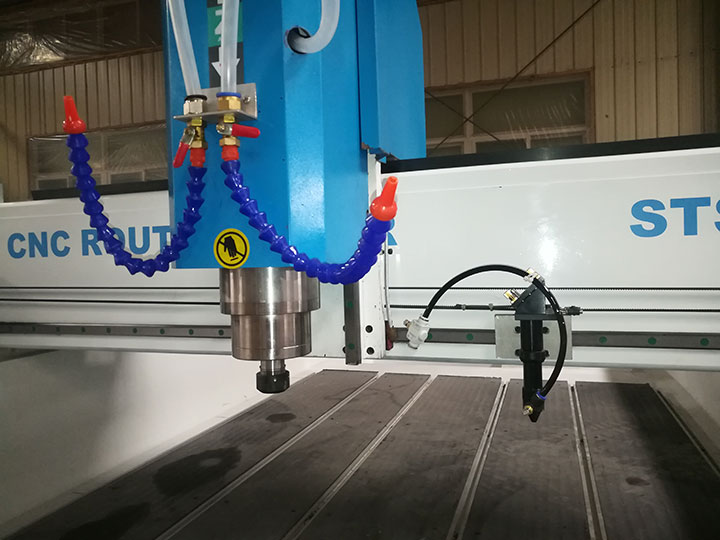

With a more powerful spindle and high-torque motor, this CNC machine can precision-cut, engrave, and etch detailed patterns, portraits, and lettering. It has an automatic tool-change system for optimizing efficiency by constantly changing cutting bits whenever needed. Its water-cooling system prevents overheating while minimizing dust levels, ensuring a clean working surface and extending the machine's lifespan.

The equipment is commonly used in monument plants, stone workshops, and memorial shops. Through its easy-to-use CNC technology, operators can achieve intricate 3D carvings and custom inscriptions without much effort. With little manpower required, companies can mass-produce quality headstones, keeping memories intact with ease and finesse.

Features of Automatic 4x8 Stone CNC Machine for Headstone, Memorial Stone, Tombstone

1. The machine bed is welded by a thick wall steel seamless tube, high-temperature tempering treatment, high rigidity, and bearing strength better.

2. Dual motor drive for Y-axis, moving stably.

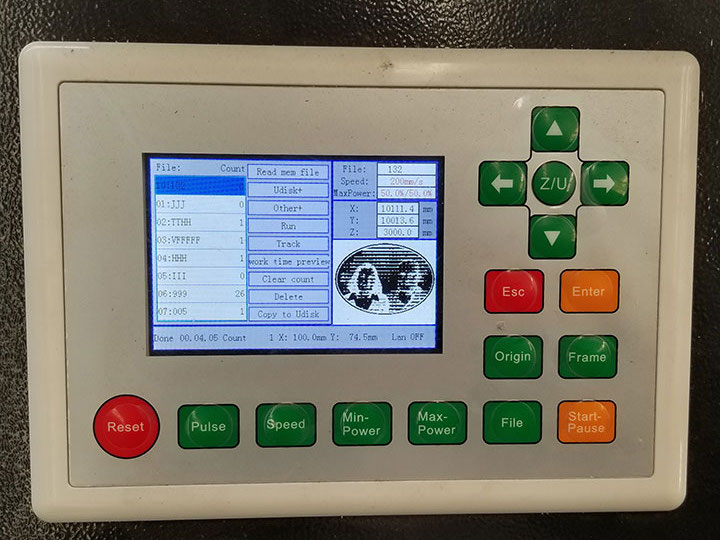

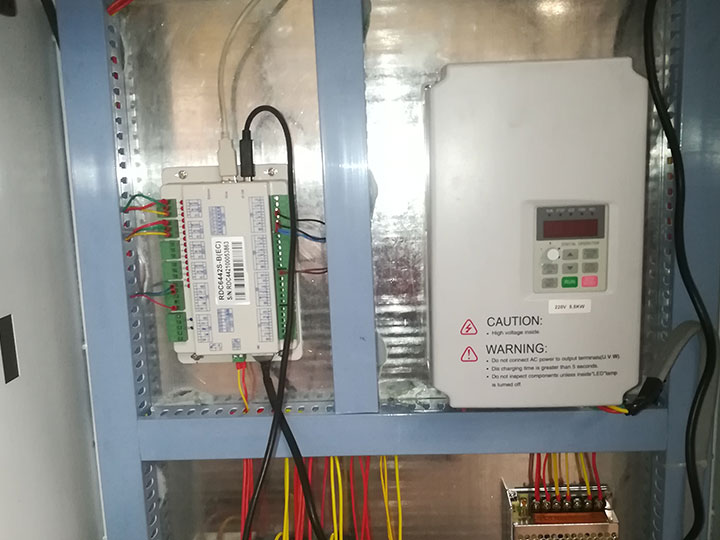

3. DSP control with good software compatibility, suitable for Type3, Artcam, and JD paint. RDworks for laser control, a professional motion control chip, has the function of consecutively high-speed curve cutting and the shortest path selection, which largely improves your working efficiency.

4. 5.5KW big torque spindle motor, strong carving strength, high efficiency.

5. High precision rack and pinion transmission, fast speed.

6. Imported linear square guide way, double row 4 row slider, high precision, long lifetime.

7. Well-selected electrical accessory, let the failure rate to the minimum.

8. With water and automatic water supply and cooling system.

9. Dustproof and waterproof design, better to protect the machine driving part.

10. Rotary device for option.

Technical Parameters of Automatic 4x8 Stone CNC Machine for Headstone, Memorial Stone, Tombstone

| Model | STS1325H |

| Working Area | 1300x2500x300mm |

| Traveling Positioning Accuracy | ±0.03/300mm |

| Repositioning Accuracy | ±0.03mm |

| Frame | Welded Structure |

| X, Y Structure | Rack and Pinion Drive, Hiwin Rail Linear Bearings |

| Z Structure | Hiwin Rail Linear Bearings and Ball Screw |

| Max. Engraving Speed | 3000mm/min |

| Spindle power | 5.5KW |

| Laser power | 80W |

| Drive Motors | Stepper System |

| Working Voltage | AC380V/50HZ,3PH (Option: 220V/60HZ) |

| Command Language | G Code |

| Operating System | DSP System +RDworks |

| Computer Interface | USB |

| Flash Memory | 128M(U Disk) |

| X,Y Resolution | <0.03mm |

Details for Automatic 4x8 Stone CNC Machine for Memorial Stone, Headstone, Tombstone

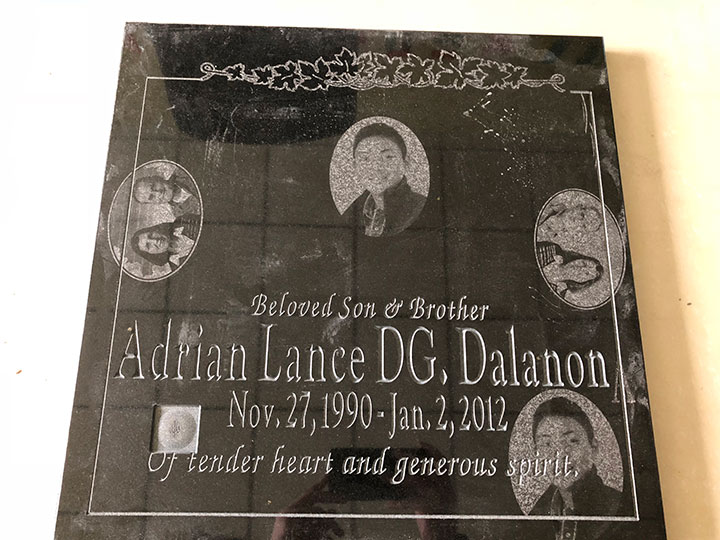

Multi-purpose stone CNC Machine for Headstone, Memorial Stone, and Tombstone in factory

4x8 Stone CNC Machine for Headstone, Memorial Stone, Tombstone Details Show

Stone CNC bit + Laser head

Stone CNC machine DSP controller

Stone CNC laser engraving machine controller

Electronic box for stone CNC machine

Applications of Automatic 4x8 Stone CNC Machine for Tombstone, Headstone, Memorial Stone

Applied Materials

Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, crystal, glass, plastic, wood, bamboo, and so on, it can do 3D embossment, line carving, bevelling, and laser engraving.

Applicable Industries

Stone Industry: Headstone, memorial stone, granite tombstone, natural marble, granite, bluestone, sandstone, artificial stone, milestone, ceramic tile, jade, etc.

Kitchen Ware Industry: Man-made marble cabinet table surface.

Artwork Decoration Industry: Woodcrafts, gift boxes, jewelry boxes, and other exquisite art crafts.

Mold Industry: Engraving copper, aluminum, and other metal molds; Building models, shoes, badges, embossed mold, biscuits, candy, and chocolate mold; Artificial marble, plastic sheeting, PVC, wood, foam, and other non-metallic mold.

Advertising Industry: Billboard, signage, badges, logo, company plate, signs, emblem, badges, display panels, fair signs, building numbers, signs of decoration, literal hole cutting, etc.; 3D character cutting, acrylic cutting, LED/neon channel, lightbox;

Users can cut and engrave non-metal material including acrylic, color plate, ABS board, rubber, plastic, cloth toys, leather, wool, crystal, glass, ceramic tile, jade, bamboo products and wood products using laser head.

Automatic 4x8 Stone CNC Machine for Headstone, Memorial Stone and Tombstone Projects

Comparison of Automatic and Manual Methods of Stone Engraving

Stone engraving is now diversified in two large areas that started with manual hand-chiseled techniques and reached machine-based CNC high-precision technology. This provides businesses along with artists the freedom of making their decisions. Skilled stone artisans use hammers along with sandblasting along with chisels to create delicate stone details by hand effort. Experience and manual engagement together with patient manipulation characterize this process. Hand engraving presents special artistic possibilities but requires lengthy performance with insecure results that limit its use for industrial production processes.

Automatic engraving enables CNC (Computer Numerical Control) technology to produce impeccable and precise cuts of designs. Programmed by a CNC machine a powerful spindle system performs coderowned designs for stone sculpture signs like patterns and letters and portraits. The standardized output of this method enhances production output but minimizes labor requirements. The automatic engraving method is suitable for companies that demand large-scale production quantity at the artistic level comparable to human work.

| Manual Engraving | Automatic CNC Engraving |

| Depends on skill level, prone to minor errors | High precision with computer-guided accuracy |

| Time-consuming, and can take hours or days | Fast, completes projects in minutes to hours. |

| Physically demanding, and requires years of expertise. | Minimal labor, machine-controlled process |

| Limited by hand skills and tools | Engraves detailed patterns, portraits, and 3D designs |

| Suitable for custom, small-scale work | Ideal for mass production and business scaling |

| Low initial cost but high labor expense | Higher initial cost but lower long-term labor cost |

| Works on most stones but takes longer on harder surfaces. | Can handle hard stones like granite efficiently |

Both engraving methods have their advantages, but for businesses aiming for efficiency, precision, and scalability, CNC automation is the superior choice. However, manual engraving remains valuable for unique, artistic, and custom-designed projects where human touch matters.

How to Maintain and Extend the Life of Your Stone CNC Machine?

Those buying a stone CNC machine should take note of maintenance properly because it guarantees uninterrupted system operation. Regular maintenance of a stone CNC machine increases functional efficiency while preventing maintenance expenses. The ensuing maintenance process will guarantee your machine runs in top working condition with its durability extended.

Clean the Machine after Each Use

Stone engraving creates a lot of dust along with debris that accumulates in moving parts thus slowing down efficiency when in operation. Maintenance starts by sweeping work stations and wiping down machine surfaces before eliminating all debris from the spindle and rails following use. A blower powered by air along with vacuum devices is a prevention against buildup.

Lubricate Moving Parts Often

Normal friction leads to deteriorating conditions of CNC machine ball screws and linear guides as well as bearings. Frequent use of the appropriate lubricants allows both machines to move smoothly without damage occurring prematurely. Use the manufacturer's guide to determine best lubricants and schedule their applications.

Inspect and Replace Worn-out Tools

The standard usage period of engraving bits and cutting tools leads to a progressive degradation that affects the quality of the engraving result. Loading a spindle with poor quality tools causes rough edges and overloads the rotating axis. The inspection rate for tools should be high and replacement should be done whenever damage or wear has reached an unacceptable level to prevent both imprecision and machine stress.

Examine the Cooling System and Water Circulation

Performance of the spindle and engraving deteriorates if it gets overheated since an effective cooling system acts as a protective mechanism. Periodic chiller unit inspection and water pipes coolant levels have to be ensured to ascertain uninterrupted cooling performance. All filters need to be cleaned or replaced with the help of distilled water to prevent scale deposit.

Keep Software and Firmware Updated

CNC software and firmware updates often include performance improvements and bug fixes. Keeping your system up to date ensures better machine compatibility, smoother operation, and access to the latest features. Always download updates from trusted sources and back up important settings before installation.

Package and Shipping of Automatic 4x8 Stone CNC Machine for Memorial Stone, Tombstone, Headstone

Warranty and After-sale Service for Automatic 4x8 Stone CNC Machine for Headstone, Memorial Stone, Tombstone

• Warranty time: one year on parts from the date of the shipping date, 3 additional years on a free repair. Lifetime technical support.

• Exceed warranty period: if the stone CNC machine parts have any problems, we can offer new machine parts at cost price and you also should pay all the shipping costs.

• After buying an item, we will send you a friendly user manual and the videos about installation, operation, and maintenance of the CNC machine step by step.

• Our technician can give you remote guide online(Teamviewer/Skype/Whatsapp/viber/Tel/Mob, etc) if you have any questions.

• 24-hour technician professional and timely after-sale service online or by email or call

• If you need it, we will arrange for technicians to go abroad to install or maintain the machines.

• Free training course in our factory.

Joseph Joyce

Bosch

Keith Knowles

Wow, I'm so pleased with the STS1325H. Thank you for a great CNC machine. I'm still learning the best settings for different stones.