I've never used an automatic machine like this before only handheld edge bander. The edge banding machine went together with software installation and debugging in about 2 hours. I was happy with how easy it was to assemble the kit and get started. It took about 5 minutes to make one board. Take a look at it under magnification, the banding matches the reveal side the plywood perfectly and does not show seams.

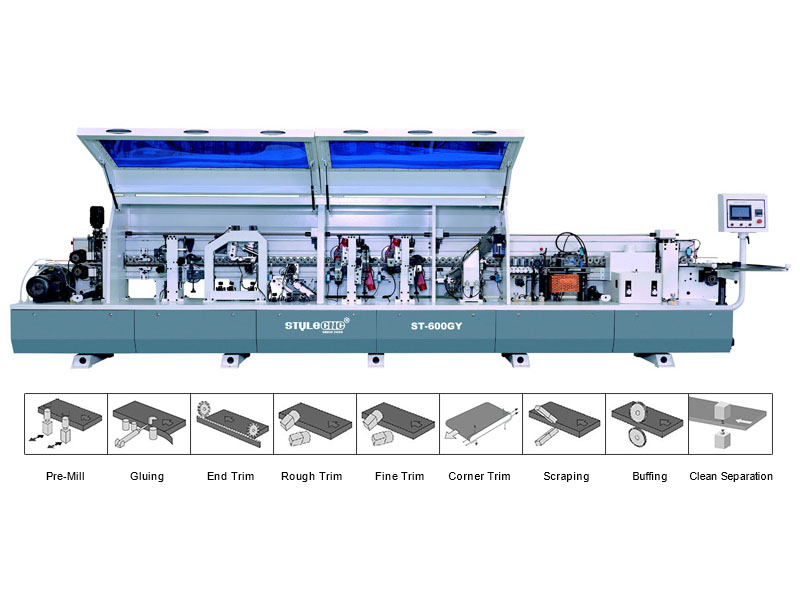

Automated Industrial Edge Banding Machine for Woodworking

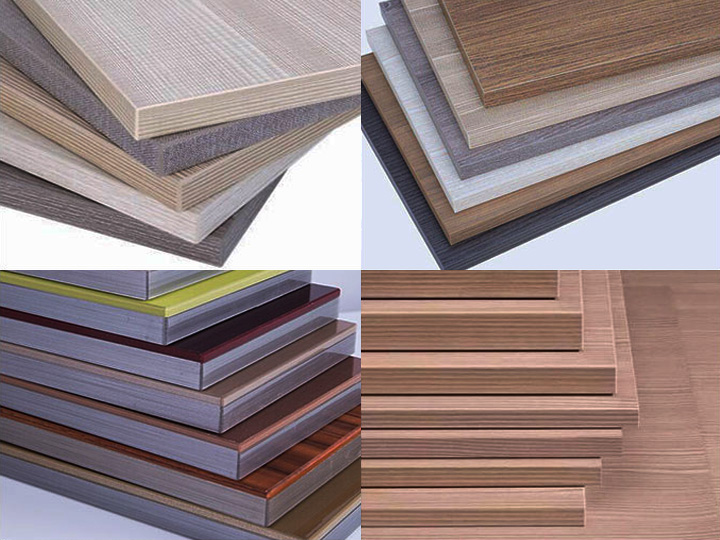

Get best deals on automated industrial edge banding machine to upgrade handheld edge bander for MDF, block board, solid wood board, particle board, polymer doors, plywood, and aluminum honeycomb panel in assembly line mass production.

- Brand - STYLECNC

- Model - ST-600

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 4525x1000*1600mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What Is An Automatic Industrial Edge Banding Machine?

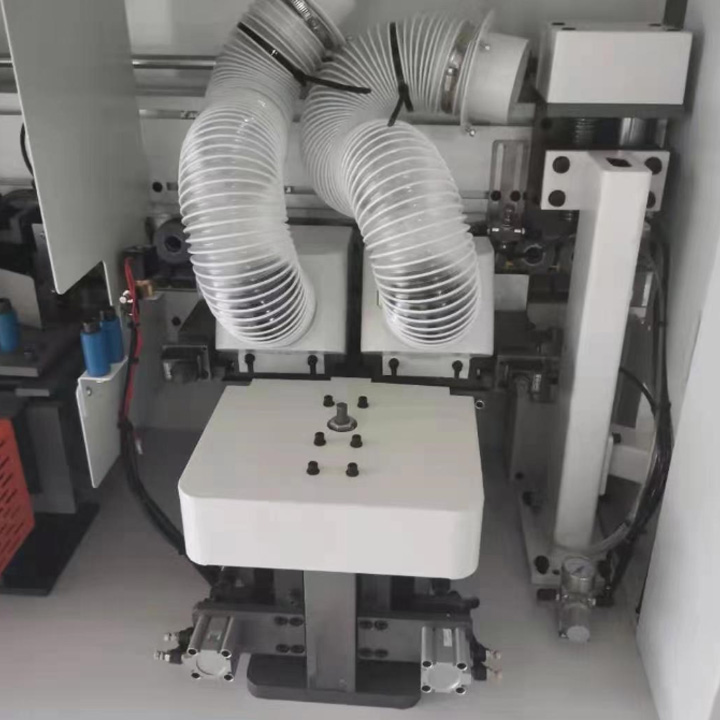

An automatic industrial edge banding machine is a power tool used for straight edge banding and trimming of MDF, plywood, block board, solid wood board, particle board, and polymer door panels in assembly line mass production. An industrial automatic edge bander machine is composed of the bed frame, the edge banding module, and the automatic control system. It has the ability to bond and press, flushing, chamfering, rough trimming, fine trimming, scraping, polishing, and additionally, pre-milling, corner rounding, tracking, and grooving can be added upon request. The industrial automatic edge banding machine is stable, reliable, and durable, and the price is affordable. It is specially designed for furniture and cabinet manufacturers.

Automated Industrial Edge Banding Machine Features

1. The automatic edge banding machine is a new, compact, high-efficiency linear edge banding machine, which is favored by woodworking furniture manufacturers.

2. All the parts are made with fine processing of a high-precision CNC machining center, and this ensures stable and high-efficiency operation.

3. The structure is compact, the layout is reasonable, and the appearance is beautiful; it adopts devices such as sound insulation, dust collection port, and anti-overload.

4. The automatic edge banding machine is mainly suitable for straight edge banding of plywood, fiberboard, particle board, and other sections.

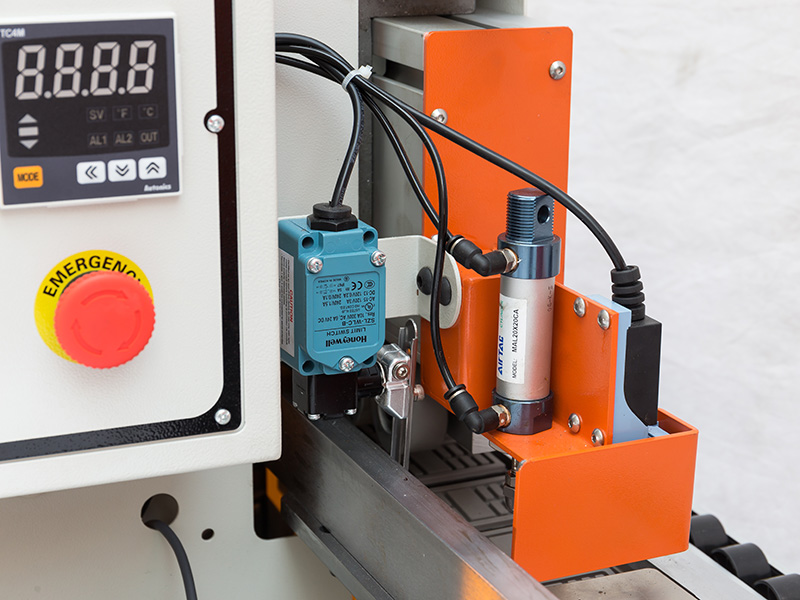

5. Pneumatic clamping bar, easier operation when the edge thickness changes.

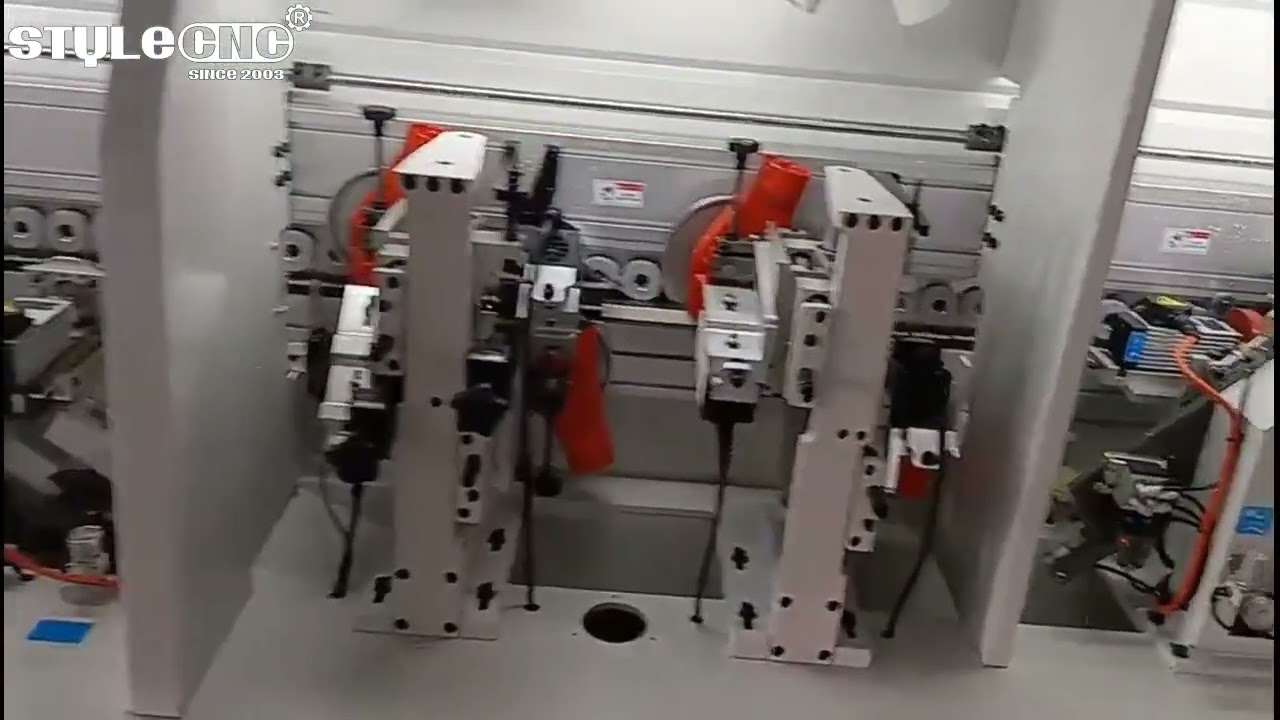

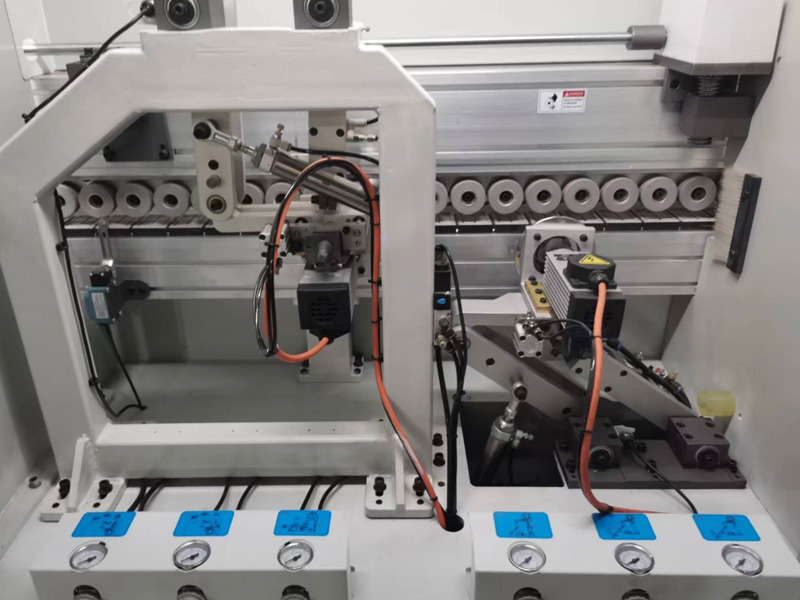

6. It has working units such as an edge banding tray device, preheating device, gluing device, welt device, finishing device, edge scraping device, polishing device, and automatic aligning device.

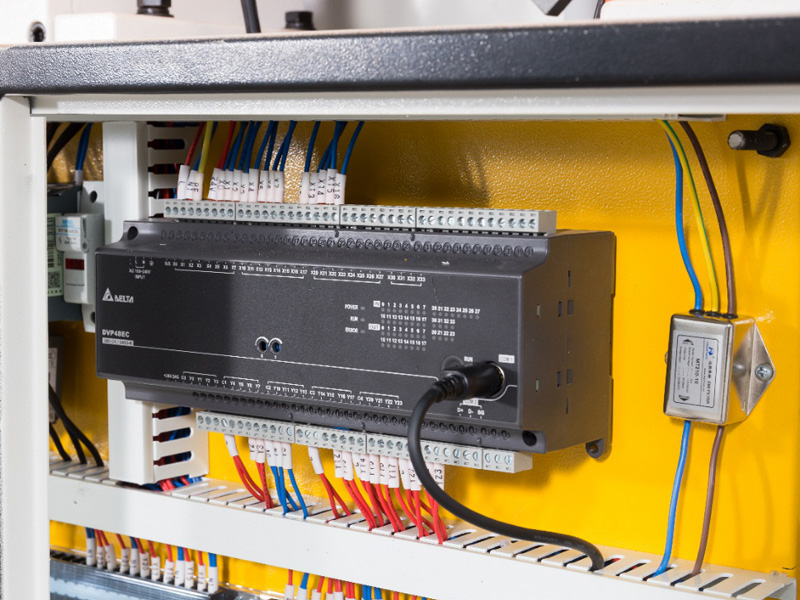

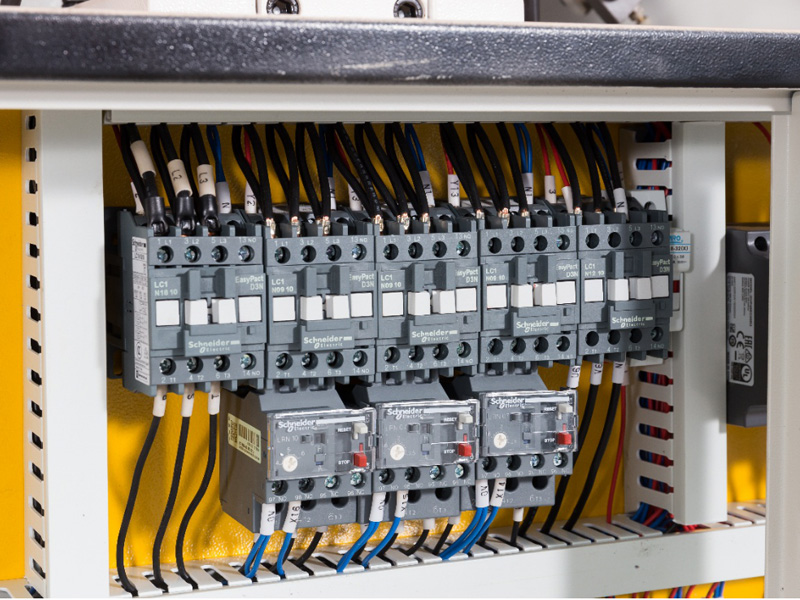

7. High-performance electrical appliances are used with high control performance, and frequency converters are used to control high-speed motors.

8. The electrical components are supplied by SCHNEIDER, OMRON, DELTA.

9. The automatic edge banding machine adopts a good pressure regulating valve to control the airflow so that each workpiece can be processed and assembled more accurately. Each process is inspected according to the strict requirements of technology.

10. The strict and elaborate assembly process ensures each piece of equipment gets to its perfect performance.

11. The automatic edge banding machine adopts a heavy-duty drag motor, and the strong drag force is stable and durable.

12. TAIWAN AIRTAC air-operated to ensure the accuracy.

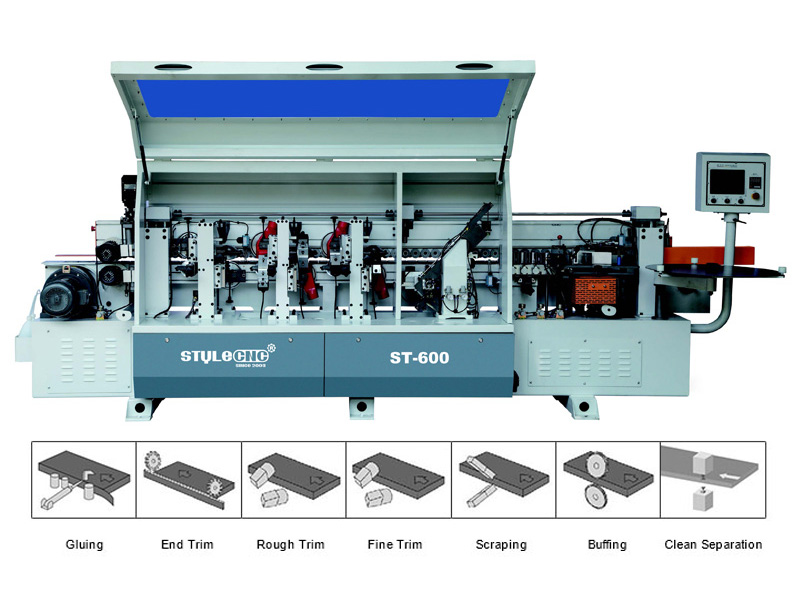

ST-600

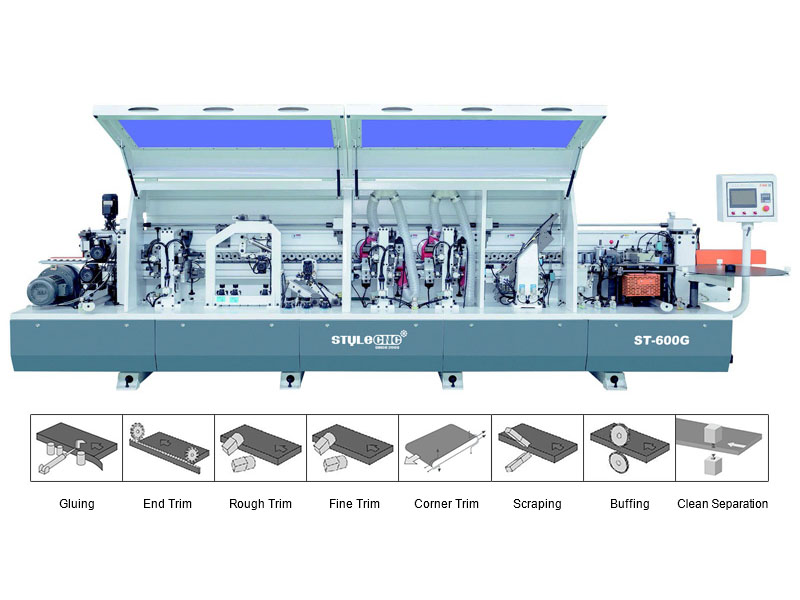

ST-600G

ST-600Y

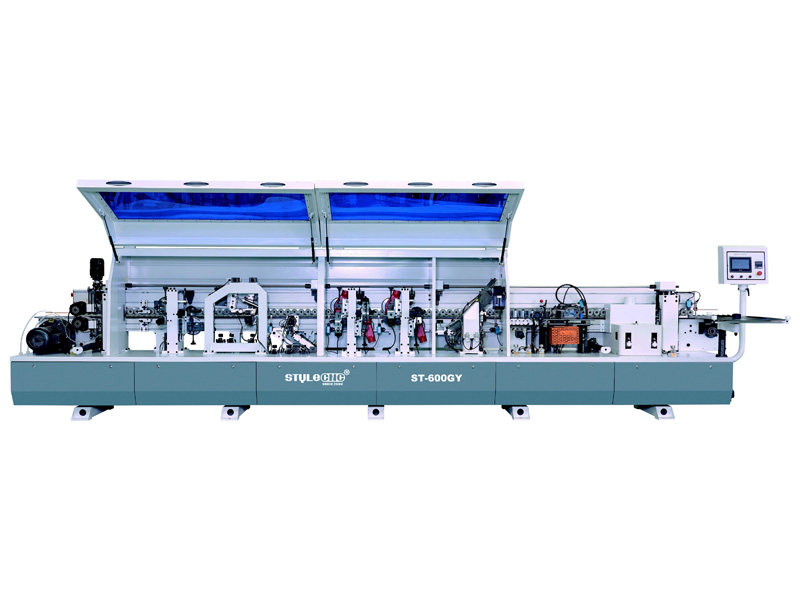

ST-600GY

Automated Industrial Edge Banding Machine Technical Parameters

| MODEL | ST-600 | ST-600G | ST-600Y | ST-600GY |

| Total power | 9.5KW | 11.2KW | 14.5KW | 16.5KW |

| Dimension | 4525x1000*1600mm | 5675x1000*1600mm | 5475x1000*1600mm | 6625x1000*1600mm |

| Feed speed | 12-17-20m/min | 12-17-20m/min | 12-17-20m/min | 12-17-20m/min |

| Board Thickness | 10~60mm | 10~60mm | 10~60mm | 10~60mm |

| Edge thickness | 0.3~3mm | 0.3~3mm | 0.3~3mm | 0.3~3mm |

| Board width | ≥80mm | ≥80mm | ≥80mm | ≥80mm |

| Board length | ≥120mm | ≥120mm | ≥120mm | ≥120mm |

| Working pressure | 0.6MPa | 0.6MPa | 0.6MPa | 0.6MPa |

| Weight | 1500kgs | 1870kgs | 1900kgs | 2300kgs |

| Thickness adjust | Manual | Automatic | Automatic | Automatic |

| Pre-milling | × | × | √ | √ |

| Gluing | √ | √ | √ | √ |

| End cutting | √ | √ | √ | √ |

| Fine Trimming | √ | √ | √ | √ |

| Corner rounding | × | √ | × | √ |

| Scrapping | √ | √ | √ | √ |

| Sprayer cleaning | √ | √ | √ | √ |

| Buffing | √ | √ | √ | √ |

What Can An Automated Industrial Edge Banding Machine Do?

An automatic edge banding machine is used for pre-milling, bonding the edge banner to the substrate, trimming the leading & trailing edges, corner rounding, trimming top and bottom flush with the substrate, scraping any surplus, and buffing the finished edge.

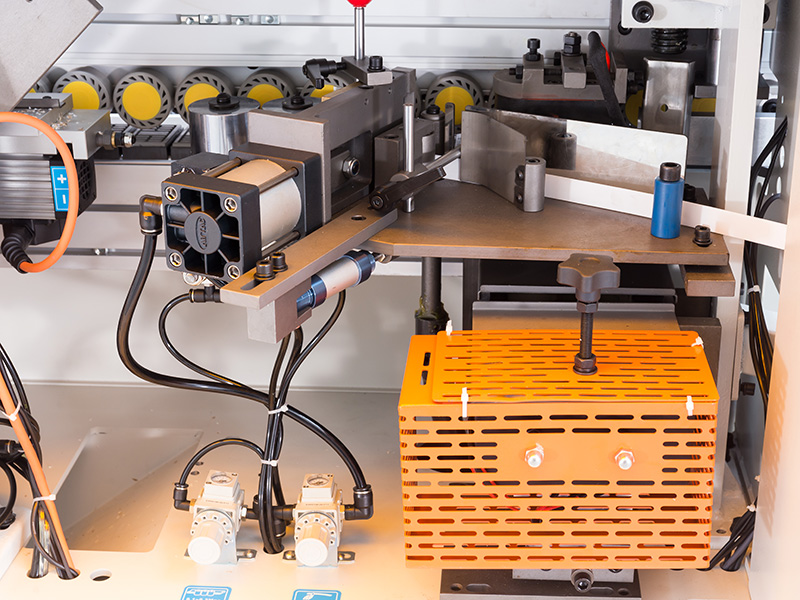

Automatic Gluing

Using the Teflon spraying process with scientific glue design, can make the temperature of the glue in the pot more uniform without carbonization and maintain good fluidity.

Pressing

Pneumatic with adjustable stroke on two wheels makes the pressing adjustment easier. It can be adjusted according to the thickness of the banding edge. Improved adhesive properties of glue and side tape.

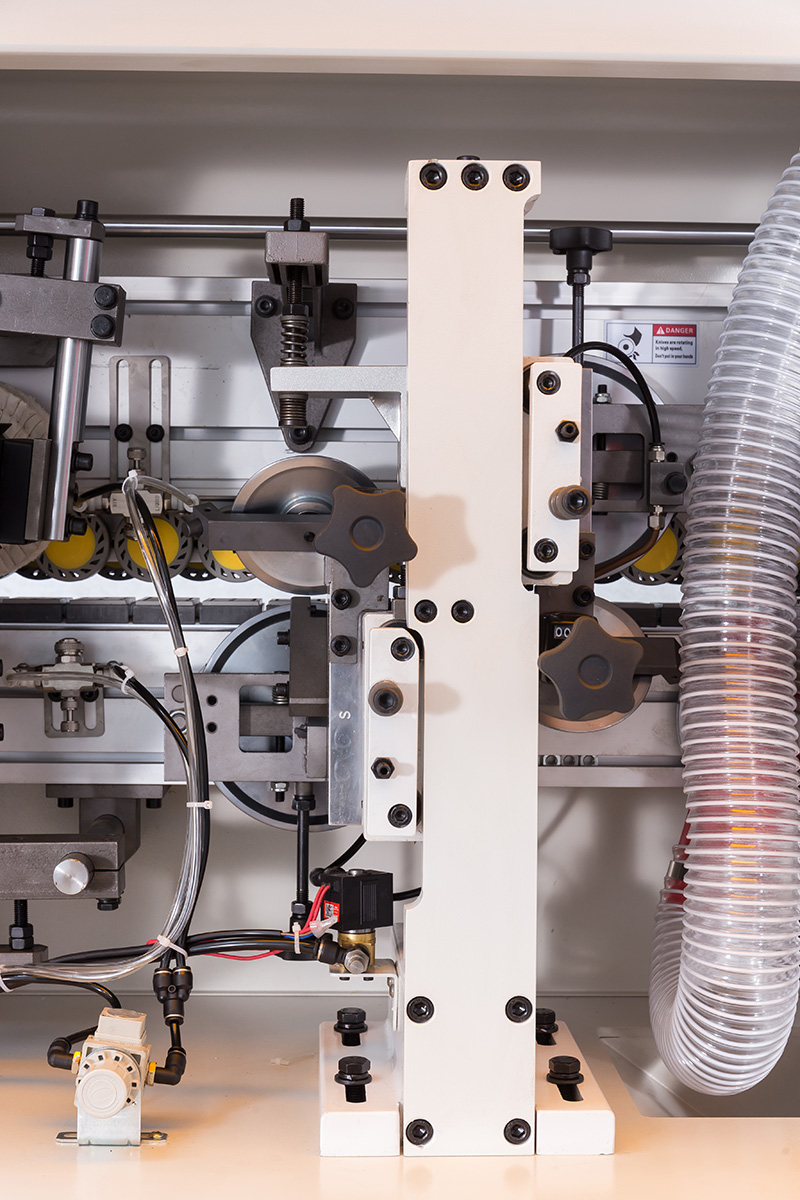

End Cutting

The air pressure balance device makes the head more stable and easier to adjust.

Optimized air circuit design, reduced noise, and improved equipment efficiency.

The high-speed cutting device is equipped with 2 pieces 0.35kw saw, and independent high-frequency control.

Fine Trimming Part with Double Saw

The stable frame design reduces the jitter of the tool during high-speed cutting, which leads to the instability of the trimming quality.

The design of the cutting edge is optimized to make the edge of the workpiece more perfect.

Scraping

The small and compact scraping device solves the problem of heavy glue lines.

At the same time, the excess bands are trimmed again to make the bands more beautiful.

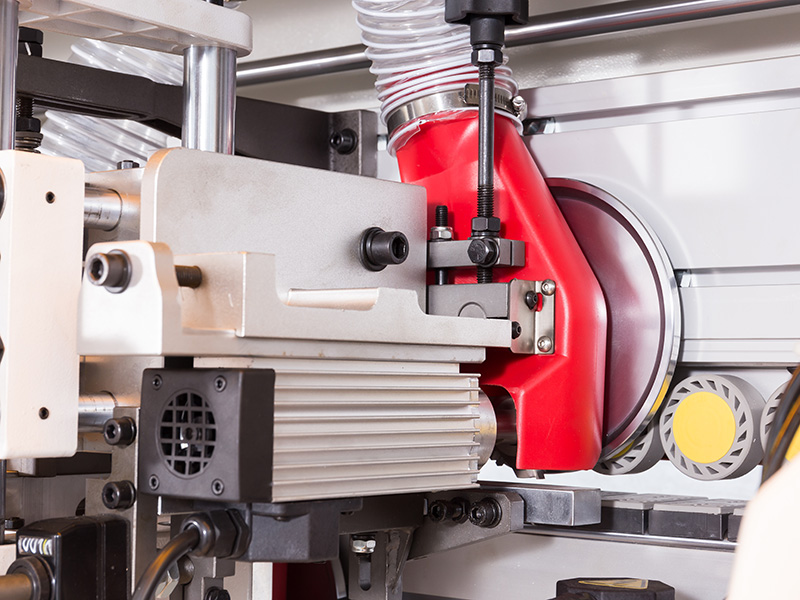

Sprayer Cleaning and Buffing

The board is cleaned by an air sprayer and then polished by a cotton polishing wheel to make a more smooth surface.

Pre-Milling (Optional for ST-280Y and ST-280GY)

It is equipped with double trimming blades that work on the wave effect that is caused by the panel saw.

Pre-milling cutters with diamond cutters ensure right-angled and chip-free workpiece edges.

Corner Rounding (Optional for ST-280G and ST-280GY)

Double heads corner rounding, and high precision guaranteed a perfect look and touch.

Automated Industrial Edge Banding Machine Parts & Accessories

Stable Conveyor Motor

Machine feeding speed can be 12m/min.

Rotary Table to Support Edge Sealing Belt

Single table design, heavy load.

Delta Colorful Touch Screen

Easy to operate.

Taiwan Airtec Pneumatic Components

Small space position, light structure, beautiful appearance, can withstand large lateral load.

Taiwan Delta PLC

Taiwan Delta Inverters

Oil Lubrication and Oil-Water Separator

Schneider Electric Parts

What Are Automated Industrial Edge Banding Machines Used For?

The automatic edge bander machine is suitable for MDF, block board, solid wood board, particle board, polymer doors, plywood, and aluminum honeycomb panels. It is used for covering the exposed sides of panels and boards such as MDF, plywood, or particle board, creating decorative edges, increasing durability, and giving a more valuable appearance. It is designed for manufacturers of large and medium-sized furniture, cabinets, and other panel furniture.

Automated Industrial Edge Banding Projects

Common Mistakes to Avoid During Edge Banding

Edge banding is an exacting process, but avoiding common mistakes makes it easier and the results much better. A few things to watch out for include:

· Not using the right edge banding material leads to peeling or poor adhesion. Always match up the edge banding material with the core material for better bonding and durability.

· Insufficient or excessive adhesive application can lead to poor lamination or excessive residue, respectively. Apply the right adhesive and apply it uniformly to ensure a clean, firm bond.

· Dirt and unevenness on either edge can affect adhesion. Thoroughly clean and smoothen the edges before applying the band for a strong and seamless finish.

· An uncalibrated edge banding machine may cause misalignment or uneven trimming. Check and adjust your machine settings for precision periodically.

· Insufficient or excessive heat application will weaken the adhesive bond. For adhesive and material type, recommended temperature settings should be observed.

· Accidents may also result from a lack of protection or safety measures. Prioritize safety at all times by following the operating guidelines of the machine and using proper equipment.

· Going straight into production without testing can result in mistakes. Always test the edge banding process on a sample piece to ensure the setup works.

· A poorly maintained machine can also give variable results. Keep your edge banding machine clean and serviced regularly to maintain it in the best working condition.

Comparing Manual and Automated Edge Banding Machines

Manual edge banding machines are a cost-effective choice for businesses focusing on custom projects or low production volumes. Automated machines, however, are best for larger operations requiring speed, precision, and efficiency. Assess your specific needs and resources to decide which is right for you. Both types offer unique advantages, and understanding their differences can help you make an informed decision for your woodworking projects.

| Manual Edge Banding Machines | Automated Edge Banding Machines |

| Operated by hand, requiring skilled labor for precise work. | Uses a fully automated process with minimal human intervention. |

| Slower processing time, suitable for small-scale projects. | High-speed operation, ideal for mass production. |

| Depends on the operator’s expertise, with a higher chance of inconsistency. | Consistently accurate and precise across all workpieces. |

| Lower upfront cost, making it accessible for small workshops. | Higher initial investment but offers long-term savings in labor. |

| Suitable for custom, intricate work where flexibility is key. | Best for repetitive tasks and uniform results in high-volume projects. |

| Easier to maintain and repair due to simpler mechanics. | Requires specialized maintenance and servicing for advanced systems. |

| Demands a skilled operator for quality results. | Minimal skill needed once the machine is programmed correctly. |

| Consumes less energy but may require more labor resources. | Generally more energy-intensive but highly efficient in productivity. |

| Handles a wide variety of edge banding materials manually. | Limited to materials compatible with the automated system’s settings. |