Economic CNC Side Holes Drilling Machine for Sale

The economical CNC side hole drilling machine is an economical and affordable fully automatic holing machine, which completely replaces the traditional drill bit, gets rid of the traditional drilling mode, uses the laser positioning system to automatically detect the surface hole position, and then performs high-speed side holing.

- Brand - STYLECNC

- Model - SH-II

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 2800mm x 1300mm x 50mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

What is an Economic CNC Side Holes Drilling Machine?

An economic CNC side holes drilling machine is a specialized tool designed to automate the process of drilling side holes in wooden panels, making it an essential piece of equipment for furniture production and woodworking businesses. Unlike traditional drilling methods that require manual effort and measurements, this machine uses advanced laser positioning and CNC technology to achieve precise and efficient drilling.

What makes it "economic" is its affordability and cost-effectiveness while still delivering high-speed, high-accuracy performance. It features multiple working stations, allowing users to drill single, double, or triple boards simultaneously, significantly improving production efficiency. Equipped with a professional controller and a user-friendly touch screen, it ensures ease of operation even for beginners.

This machine is widely used in panel furniture manufacturing, cabinet making, and other wood-based industries. It efficiently handles various types of holes, including three-in-one side holes, pin holes, and blind holes, making it a game-changer for businesses looking to streamline their workflow. By eliminating the need for traditional drills, it saves time, reduces labor costs, and enhances overall productivity in woodworking operations.

CNC Side Holes Drilling Machine Features

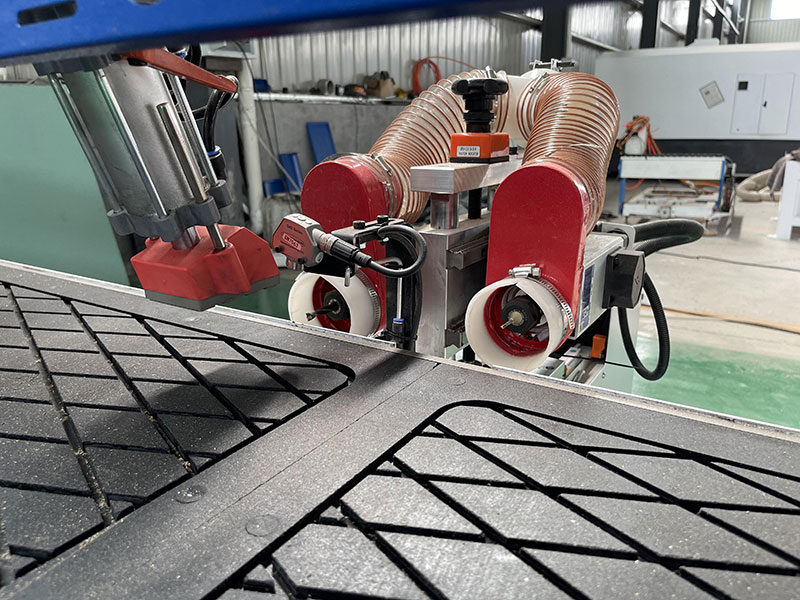

1. Economical CNC side drilling machine with 3 partition working stations, single, double, and 3 station modes can be switched, 3 pieces board can be also loaded to drill at the same time.

2.It is equipped with 2 processing modes, set by the controller or read the code by the scanning gun.

3. The controller interface is humanized, simple, and easy to learn.

4. Adopts the imported Banner laser probe to keep higher drilling accuracy.

5. Welded structure by thick profiled steel stabilized under high temperature, ensures minimum distortion, excellent rigidity, and powerful strength.

6. High-speed servo motor with reducer makes machine stable running with low noise and high accuracy.

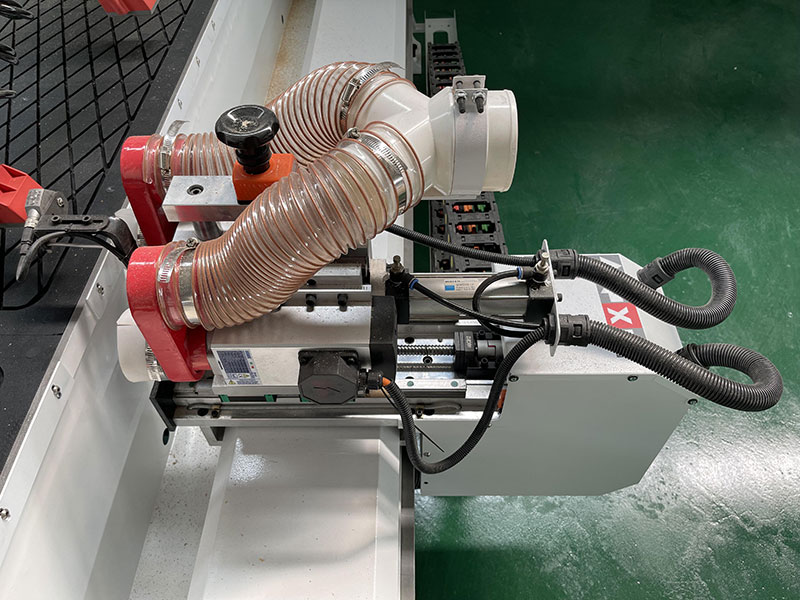

7. SH-II side drilling machine with 2 spindles, which can hold 2 pieces different tool bits. One bit is used for making side holes, the other one is for making slots. It is easy to use and doesn't need to change tool bits to save time.

CNC Side Holes Drilling Machine Applications

Economic CNC side holes drilling machine is a professional CNC machine to complete 3-in-one side holes, wood pin holes, blind holes, fixed grooves, through grooves, and side hole drilling for hidden cabinet handles.

It replaces the traditional drill completely and gets rid of the traditional punching mode, it can also automatically detect the surface holes by laser, and then do side holes.

Applicable industries: Wood art craft, panel furniture, whole house customization, blister door panels, tables and chairs doors, and Windows. The horizontal board and vertical board side holes on the cabinet.

CNC Side Holes Drilling Machine Technical Parameters

| Model | SH-II |

| Spindle | HQD air cooling spindle 2.2kw |

| Motor | 750W servo motor |

| Control system | Professional controller+touch screen 7inch |

| Working area | 2800*1300*50mm |

| Bed structure | Steel welded structure |

| Y axis | Taiwan TBI ballscrew transmission |

| X axis transmission | Rack and pinion transmission |

| Z axis transmission | Pneumatic cylinder |

| Guide | Taiwan linear guide rail |

| Max working speed | 10-180/min |

| Machine size | 3300 x 1300 x 1450mm |

CNC Side Holes Drilling Machine Details

What Can A CNC Side Holes Drilling Machine Do?

How Laser Positioning Enhances Accuracy in CNC Side Hole Drilling?

Precision is the backbone of modern woodworking, and even a small misalignment can lead to costly material waste and assembly issues. This is where laser positioning technology plays a vital role in CNC side hole drilling. By integrating high-precision laser sensors, CNC machines ensure accurate hole placement, improve efficiency, and enhance the overall quality of furniture production.

Eliminates Manual Measurement Errors

Traditional drilling methods rely on manual measurements and markings, which are prone to human errors. Laser positioning technology removes this uncertainty by precisely detecting the edges and surfaces of the workpiece, ensuring that holes are drilled in the exact required locations every time. This results in fewer defects and higher-quality output.

Ensures Consistent Accuracy Across Multiple Workpieces

When producing furniture or cabinets in bulk, consistency is key. Laser positioning allows CNC side hole drilling machines to maintain uniform accuracy across multiple boards, regardless of size or thickness. Each workpiece receives perfectly aligned holes, reducing misfits and rework, and ensuring seamless assembly of final products.

Detects Material Surface Variations

Wood panels may have slight warps, bends, or thickness variations that can affect drilling accuracy. Laser sensors can scan the surface of each panel in real time, adjusting drilling positions accordingly. This adaptive capability prevents misalignment caused by uneven surfaces, improving the machine’s ability to handle different wood materials.

Speeds Up Production Without Compromising Precision

Laser positioning enables CNC machines to locate drilling points instantly, eliminating the need for pre-marking and manual adjustments. This significantly speeds up the drilling process, allowing operators to complete more work in less time while maintaining pinpoint accuracy. Increased efficiency translates into faster turnaround times and higher productivity for businesses.

Reduces Material Waste and Saves Costs

Misaligned holes or incorrect drilling often lead to wasted materials and additional labor costs. With laser-guided positioning, errors are minimized, ensuring every drilled hole is perfectly placed. This reduces waste, optimizes material usage, and ultimately lowers production costs, making CNC side hole drilling machines a cost-effective solution for woodworking businesses.

CNC Side Holes Drilling Machine vs. Traditional Drilling Methods

Precision and efficiency are key factors in modern woodworking. Traditional drilling methods require manual effort, making them time-consuming and prone to errors. On the other hand, CNC side holes drilling machines automate the process, offering greater accuracy and speed. Let’s compare these two methods side by side.

| CNC Side Holes Drilling Machine | Traditional Drilling Methods |

| Uses laser positioning for high precision and consistency. | Relies on manual measurements, leading to potential misalignment. |

| Can drill multiple boards at once, reducing production time. | Slower process as each hole is drilled manually. |

| Fully automated with CNC control, requiring minimal manual intervention. | Manual operation requires continuous monitoring and adjustments |

| Simple touchscreen interface and preset drilling patterns. | Requires skilled workers for accurate hole placement. |

| Capable of drilling various hole types (side holes, blind holes, grooves). | Limited to the operator's skill and available tools. |

| Requires fewer workers as most tasks are automated. | Labor-intensive, requiring skilled operators for accuracy. |

| Initial investment is higher but saves costs in the long run. | Lower upfront cost but higher long-term labor and material expenses. |

| Ideal for panel furniture, cabinet making, and high-production environments. | Best for small-scale or custom one-off projects. |

While traditional drilling methods have their place in smaller workshops or custom projects, CNC side holes drilling machines are the superior choice for businesses focused on efficiency, accuracy, and large-scale production. By automating drilling tasks, they enhance productivity, reduce labor costs, and ensure high-quality output with minimal waste.

How to Choose the Best CNC Side Holes Drilling Machine for Your Business?

Choosing the best CNC side holes drilling machine is crucial for efficiency, accuracy, and long-term profitability. The right machine should match your production needs, material requirements, and budget while offering reliability and ease of use. Here are key factors to consider before making a purchase.

• Drilling Accuracy and Precision: Look for a machine equipped with laser positioning technology to ensure accurate hole placement. Precision drilling reduces errors, minimizes material waste, and ensures high-quality results for furniture production.

• Processing Speed and Efficiency: A machine with a high-speed servo motor and automatic scanning functions will improve efficiency. Faster processing speeds mean more work completed in less time, boosting overall productivity.

• Control System and User Interface: A simple, intuitive control system makes operation easier, even for beginners. Machines with a professional controller and touchscreen interface allow for quick adjustments and seamless operation.

• Machine Structure and Durability: A steel-welded frame enhances stability and ensures long-term durability. A well-built machine resists vibrations and maintains accuracy even after extended use.

• Tool Configuration and Spindle Power: Machines with dual spindles allow for both hole drilling and slot cutting without frequent tool changes. A powerful spindle ensures smooth, efficient cutting of various wood materials.

• Material Compatibility: Ensure the machine can handle different board types, including MDF, plywood, and particleboard. Versatility in material processing expands production capabilities and market opportunities.

• Automation Features: Features like barcode scanning and automatic hole detection improve workflow efficiency. Automation reduces manual labor, speeds up production, and minimizes errors.

• Machine Size and Workspace Requirements: Consider the available space in your workshop before choosing a model. A compact yet efficient design maximizes productivity without taking up excessive room.

• After-Sales Support and Warranty: A reliable supplier should provide technical support, training, and a good warranty. Strong after-sales service ensures minimal downtime and maximizes the machine’s lifespan.

Cost and Return on Investment: While price is important, focus on long-term value rather than just the initial cost. A high-quality CNC side hole drilling machine will improve efficiency, reduce waste, and offer a strong return on investment over time.