Easy set up and integrates wonderfully with CNC. I'm impressed with the machine's overall mechanical design, fit and finish. It works exactly how I would expect it to. Its professional for modern custom furniture making, all work is done automatically. And I will upgrade to use smart robotic arms instead of manual operations to achieve unattended machining in the next year.

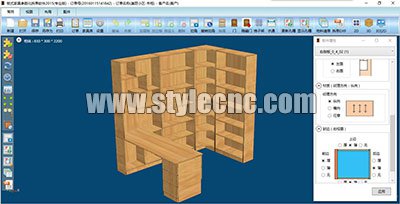

Custom Furniture CNC Router with Automatic Nesting Software

Custom furniture CNC router with automatic nesting software has full functions of automated feeding, nesting, optimizing, vertical drilling, slotting, grooving, cutting, and carving. Now the best nesting CNC machine for sale at affordable price.

- Brand - STYLECNC

- Model - S6

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 1440mm x 3040mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Features of Custom Furniture CNC Router with Automatic Nesting Software:

1. With intelligent, humanization and high automatic operation, this nesting CNC router machine can make the operator much more easier for handling all, any people can learn in couple hours for operating, it can save cost of labor.

2. Leading brand components such as Italian HSD spindle (automatic tool changer), Japanese Yaskawa servo motors, Taiwan Syntec controller, Apex reducer and transmissions ensure high efficiently.

3. Double layer vacuum table can hold small pieces for excellent cutting, realize all kinds of customized furnitures.

4. High efficiency advanced automatic tool change program, without human intervention, program automatically.

5. Through industrial grade overall welding lathe bed with tempering and aging treatment, deformation is avoided and the stability and processing precision of the machine toolare improved.

6. Carousel Tool Magazine can hold up to 8 tools. Adopted Yaskawa servo motor magazine to ensure high repeatability, high efficiency.

Custom Furniture CNC Router with Automatic Nesting Software Applications:

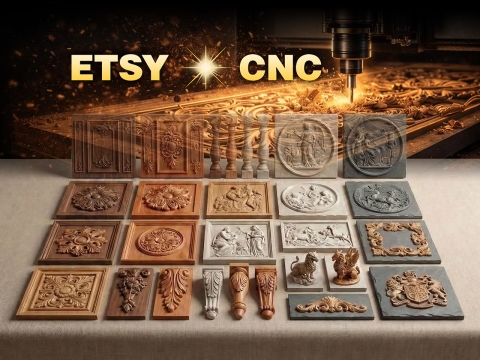

1. Furnitures: Wooden doors and furnitures, windows, tables and chairs, cabinets and panels, 3D wave plate, MDF, computer desk, musical instruments, etc.

2. Advertising: Billboard, logo, sign, 3D characters cutting, acrylic cutting, LED/neon channel, literal-hole cut, light-box mold, stamp, mound, etc.

3. Panel Machining: Insulation, plastic chemical components, PCB, car body, bowling track, ABS, PP, PE, etc.

4. Decorations: Cutting, carving, and milling of acrylic, PVC, density board, artificial stone, PMMA, plastic and soft metal plates including copper plate and aluminum plate.

Automatic Nesting CNC Router Specifications:

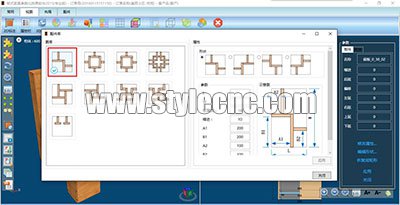

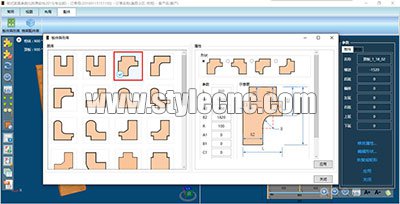

Automatic nesting software.

| High speed designing,Properties of panel is fully open which can do any modification. Rich special-shaped panel library, lattice parts library, special design, fast and intutive. According to the overall size required, quickly generate the type customer need. |

| Automatic vent hole, one click for cutting list, easy to see the hole and slot, automatically generate the cabinet statement, hardware list and plate list. |

| Joint different designs in typesetting optimization, maximize utilization to improve the rate of the board. |

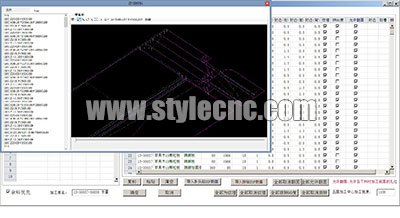

Automatic Barcode Labeling system.

| After typesetting in the software, It can intelligent generate the bar code program, top surface machining and five surface processing procedures, accurate docking backend equipment. |

| Independent labeling unit can move quickly, when the machine is cutting and drilling,at the same time, it can identify plate in advance, and automatic label the code to the sheet, the operator just need to upload the materials, no need other work, so that to be further freeing up labor. |

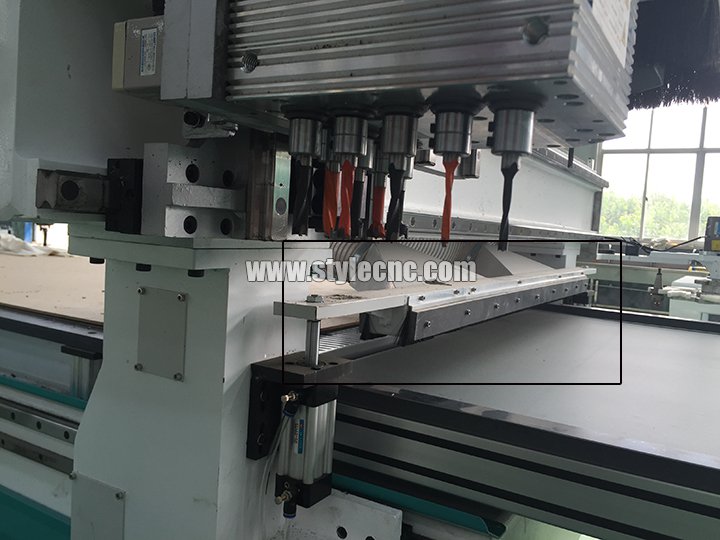

Automatic Loading system.

The automatic loading system is consist of a lifting platform which support and raise the stack of material to height same the CNC router machine's vacuum bed, which is monitored with optical sensor.

| Optical Sensor When one piece of material is taken to process, then the Hydraulic Platform will go up, when it arrival to the senor, it will automatic stop and wait the Suction Cup Load System to come. |

| Pedal control It is one remote control for the Hydraulic Platform to up and down to load materials. |

| Suction Cup Load device The suction cup load system is installed on the gantry, it can automatic go to hydraulic platform to grab the board, then drive it to the working table. |

| Automatic loading auxiliary device When the suction cup load a sheet, the auxiliary device will help to reduce resistance and more easier to travel. |

| Material Alignment device When the plate arrival to the working table, the air cylinder pins will pop up to push and fix the materials in correct location. |

Automatic pushing system.

Automatic nesting CNC router adopts pushout rod, after finishing the work on the worktable, the workpieces will be pushed to convey belt automatically,at the same time, the Suction Cup Load device

will load another board to continue working, which can save time and improve the working efficiency.

Automatic convey belt uploading system.

In the convey belt uploading table, it has two laser radiation sensor, when the workpiece arrival to the sensor, the convey will stop automatically. When the operater takes off the workpieces, the convey will continue to run until the sensor detect next workpieces.

Technical Parameters of Automatic Nesting CNC Router:

| Model | S6 |

| Table Size | 1440×3040mm |

| Traveling Positioning AccuraIT | ±0.03/300mm |

| Repositioning Positioning AccuraIT | ±0.05mm |

| Table Structure | Vacuum system |

| X, Y Structure | Gear Wheel Transmission |

| Z Structure | Ball Screw, linear square rail |

| Max. Consume power | 11Kw |

| Max.Speed | 0-32000mm/min |

| Max. Working Speed | 0-20000mm/min |

| Spindle Power Motor | 9.0kw HSD air cooling spindle |

| Spindle Speed | 0-18000RPM |

| Working Mode | Yaskawa servo |

| Working Voltage | AC380V,3PH/50/60Hz,3PH |

| Command | G Code, *uoo, *mmg, *plt |

| Operating System | Taiwan Syntec control system |

| Interface | USB |

| Flash Memory | 128M |

| Collet | ER32 |

| X,Y Working DelicaIT | <0.01mm |

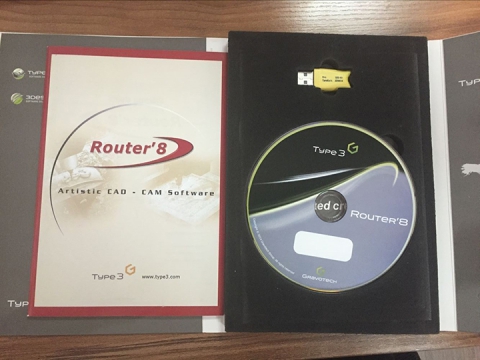

| Software | Type3 software, Wentai software, Artcam software |

| Running Circumstance | Temperature: 0°C~45°C Relative humidity: 30%~75% |

| Pump | vacuum pump |

| Packing Size | Separated: 3200X1950X1404mm Integrated: 3200X1950X1950mm |

Automatic Nesting CNC Router Projects:

Warranty and After-Sale Service for Nesting CNC Router:

1. Warranty period: two year on parts from date of shipping date, 3 additional years on free repair. Life-time technical support.

2. The nesting CNC router has been adjusted before delivery.

3. English software, user manual and detailed installation & training Videos within.

4. The nesting CNC router spare parts and repair service is offered in lifetime.

5. Free training is offered in the plant and free samples are available.

6. 24 hours technical support by e-mail, calling or door-to-door service.

7. Professional nesting CNC router manufacturer with more than 10 years experiences.

8. International quality certificate: CE, ISO9001, FDA.