Laser cutters are computer-assisted machines used in manufacturing. They can direct a focused laser beam along a pre-set path. Unlike additive methods, laser cutting is subtractive, meaning it removes material to forge precise cuts, holes, or engravings.

At STYLECNC, we're thrilled to help you learn about laser cutters. This guide covers their basics, applications, and benefits. Have a read!

What Are Laser Cutters?

Laser cutters are computerized tools that use high-precision laser beams to cut or engrave materials. While they are common in industrial settings, they're also very popular among small businesses and hobbyists. They come in a range of table sizes that make them useful in households as well as large factories.

Laser cutters are a form of CNC machines which are computerized tools that makes precise cuts. They are much faster and more reliable than manual machining.

The efficiency of a laser cutter is unmatched. It works on diverse materials -- from plastic and metal to delicate fabrics, too. This make it a top choice across industries. In short: Laser cutters deliver precision and versatility for any project.

The Advantages of Laser Cutting

It's clear that laser cutters offer unmatched precision, speed, and versatility. This is what makes them indispensable in modern manufacturing and design. Below are five reasons why they stand out.

1. Unmatched Precision

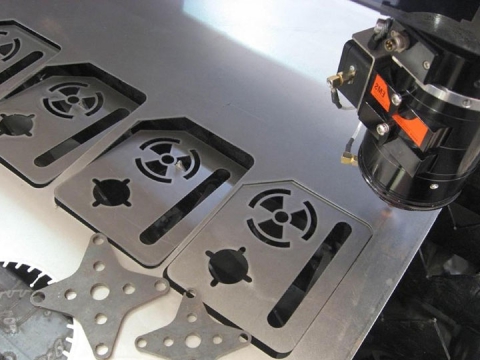

A laser cutter can deliver razor-sharp accuracy. It is capable of making the most intricate designs with tolerances as close as 0.1 mm. Unlike manually operated cutting methods, using a laser cutter lets you carve and bore out digital designs flawlessly. You can be certain of consistent results every time.

The unmatched precision of these tools makes them ideal for detailed engravings. You can use them to make the tiniest micro-cuts in addition to complicated patterns. This is regardless of whether you're working on industrial parts or a simple artistic project.

2. Material Versatility

Materials of all sorts can undergo laser cutting. Admittedly, the process sounds like its only ideal for metals like steel and aluminum. In truth, much softer materials like wood, acrylic, leather, and even fabric can be handled by laser cutters.

This material versatility is a key advantage. You can't deny the time saving element either. Laser cutters can effortlessly adapt to different thicknesses and textures without needing to make physical tool changes. This flexibility saves time and expands creative possibilities across industries—from aerospace to fashion.

3. Speed and Efficiency

We've touched on it before, but it's certainly worth repeating -- laser cutting is fast! Much faster than traditional methods. A task that usually takes hours with manual cutting can be completed in minutes. Since the cutting process is automated, no manual adjustments can interrupt the manufacturing process. This reduces downtime and, for businesses, translates to much higher productivity and lower labor expenses.

4. Smooth, Clean Edges

Tradition cutting tools like saws and blades often leave rough edges that require sanding or polishing afterward. Laser cutting, on the other hand, burns, melts or vaporizes material. This renders smooth, finished edges on processed products.

It's not uncommon for products to need smooth, professional finishes right away. This is especially true if they have to undergo further processing after cutting. Laser cutting is especially useful for ensuring this happens and removes the need for processes like sanding while improving production speeds.

5. Less Waste, More Savings

Since laser cutters use software to execute cuts, their accuracy ensures far less waste. The laser beam is so thin that very little material is wasted and more can be produced from a single piece of material. For a business or person using expensive metals or plastics, this can equate to massive cost savings over time.

Frequent Asked Laser Cutter Questions

Q1: What materials can a laser cutter work with?

Relax. Laser cutters can process a wide variety of materials. This includes wood, acrylic, leather, fabric, paper, and many metals.

Its important to note, however, that some materials like PVC or vinyl release toxic fumes when exposed to extreme heat. So, just because it can be cut with a laser, doesn't mean it should. Its a good habit to check your machine's specs for material compatibility.

Q2: Do you need special training to use a laser cutter?

Yes and no. Many modern laser cutters, especially those for household or small business use, are largely user-friendly. These require no formal training, although proper training goes a long way towards ensuring safe operation.

Larger industrial machines may require you to undergo specific formal training before you're permitted to operate them. You may need to understand the machine settings, material requirements, ventilation needs, and basic maintenance. The good news is, many suppliers offer training services with purchase.

Q3: How precise are laser cutters compared to other cutting methods?

Laser cutters offer exceptional precision, typically accurate to within 0.1mm. This makes them far more precise than manual cutting methods and often more accurate than CNC routers for detailed work. The focused laser beam allows for intricate designs and clean edges.

Q4: What safety precautions should I take with a laser cutter?

It never hurts to be careful. Key safety measures include:

• Always using proper ventilation to remove fumes

• Never leaving the machine unattended during operation

• Wearing protective eyewear

• Keeping flammable materials away

• Having a fire extinguisher nearby

• Following all manufacturer safety guidelines

Q5: What's the difference between CO2 and fiber laser cutters?

CO2 lasers are better for organic materials like wood, acrylic and fabric, while fiber lasers excel at cutting metals. CO2 lasers are generally more affordable, while fiber lasers offer faster cutting speeds on metals.

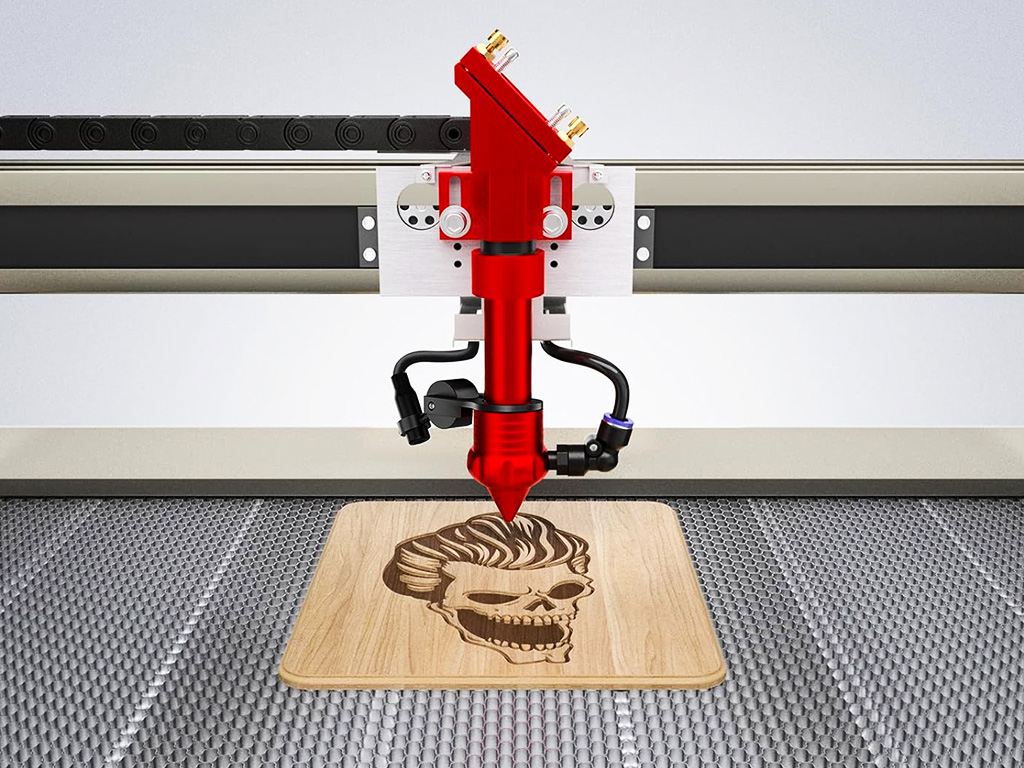

Q6: Can laser cutters engrave too?

Yes! By adjusting power/speed settings, laser cutters create precise engravings with benefits traditional methods can't match.

Where To Get A Laser Cutter?

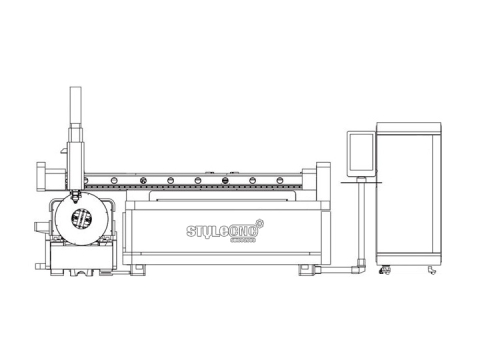

If you're looking for a high-quality laser cutter, STYLECNC offers a diverse range of options to meet various industrial and creative needs. Our product lineup includes advanced CO2 Laser Cutters, precision Fiber Laser Cutting Machines, robust Laser Metal Cutting Machines, and versatile Hybrid Laser Cutting Systems.

Whether you need cutting-edge technology for metal fabrication, intricate designs, or hybrid solutions, STYLECNC provides reliable and efficient machines. To explore their offerings further or make a purchase, contact our sales team for personalized assistance. STYLECNC is a trusted source for laser cutting equipment, ensuring performance and durability for your projects.

Conclusion

Laser cutters are transformative tools that bring precision, speed, and versatility to manufacturing, design, and creative projects. From intricate engravings to industrial-grade metal cutting, their applications are vast and their advantages undeniable. Whether you're a hobbyist, small business owner, or large-scale manufacturer, investing in a laser cutter can significantly enhance productivity and creativity.

Ready to take the next step? Explore STYLECNC's laser cutter offerings today and discover how our laser cutting technology can elevate your work. Contact our sales team for expert guidance and find the perfect machine for your projects. With STYLECNC, precision and quality are guaranteed.