Laser cutting is an automatic cutting method that replaces traditional mechanical tools with laser beams. It features with high precision, high speed, smooth cuts, low costs, and automatic typesetting to save materials.

What Is Industrial Laser Cutter?

Industrial laser cutter is a large format automated laser cutting system with CNC controller for mass production or assembly line production for commercial use in modern manufacturing.

As the most popular industrial cutting machine at present, the laser cutter has a wide range of cutting materials and powerful functions, and has been gradually introduced into the industrial manufacturing of various industries. It is used both in the manufacturing process of automobiles, ships, airplanes, robots, as well as in apparel, packaging, signage, artwork, crafts, sculpture, models, and in the manufacture of foam inserts for specific packaging.

Industrial laser cutters are an important part of modern manufacturing. Now there are many types of industrial laser cutting systems, including CO2 laser cutters and fiber laser cutters. Not only the laser generators are different, but also the applications are also different. Different materials have different features, and the absorption of laser is also different. Some materials may absorb laser in this band, but not in other bands, which makes us buy a laser machine based on the specific material properties. For items with different thicknesses, different sizes, and different shapes, different laser cutting systems will also be used in order to get better cutting results.

Industrial laser cutting machines make high-quality cut surfaces that hardly require any additional finishing. It allows the industrial manufacture of products to reach a threshold where any other technology can require extremely high costs and cumbersome processes, allowing smaller businesses to remain competitive with larger rivals.

9 Best Industrial Laser Cutters

Today I would love to share with you 9 best industrial laser cutters in modern manufacturing. You can review all of them, and choose a suitable one for your business.

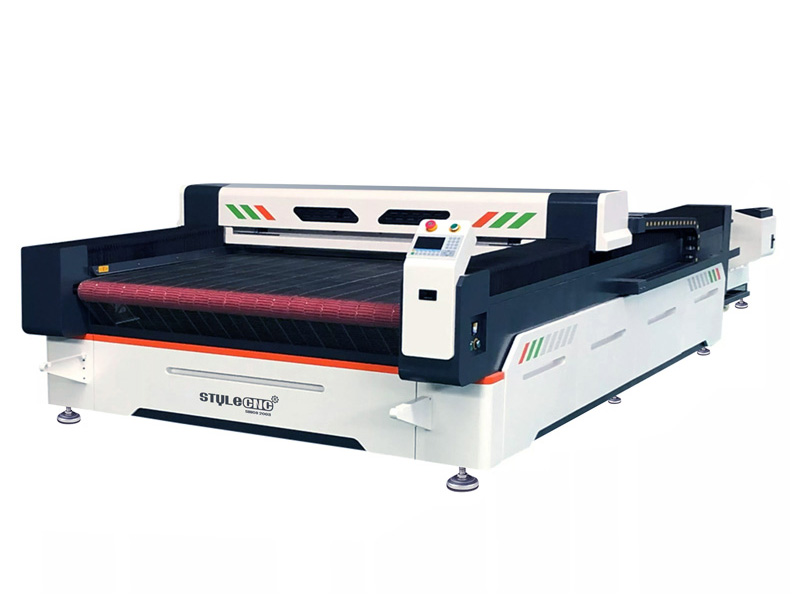

STJ1630A Industrial Laser Fabric Cutting Machine

STJ1630A

Features

STJ1630A industrial fabric laser cutter is a type of precision laser fabric cutting system with 150W CO2 sealed laser tube, automated feeder & roller, Ruida controller, stepper motor, belt transmission, CW5200 industrial water chiller, and 1600mm x 3000mm table size. CCD camera vision laser cutting system is optional for cutting fabrics, and the laser-cut fabrics are flat, edge-finished, and free of burnt edges. The industrial laser cutter is designed for fashion, garment, clothing, apparel, shoe, home textile, embroidery, trademark, toy, umbrella, leather, luggage, purification, medical, warp knitting, and aviation.

Costs

STJ1630A industrial laser fabric cutter has a standard price of $9,500, and up to $16,000 based on optional parts.

Pros

• Easy to use with automatic feeding.

• Precision cutting with high speed & quality.

• STYLECNC's exclusive automatic typesetting system to save material.

• The trajectory of the laser head can be simulated and displayed to optimize various paths.

Cons

• The materials that can be cut are limited.

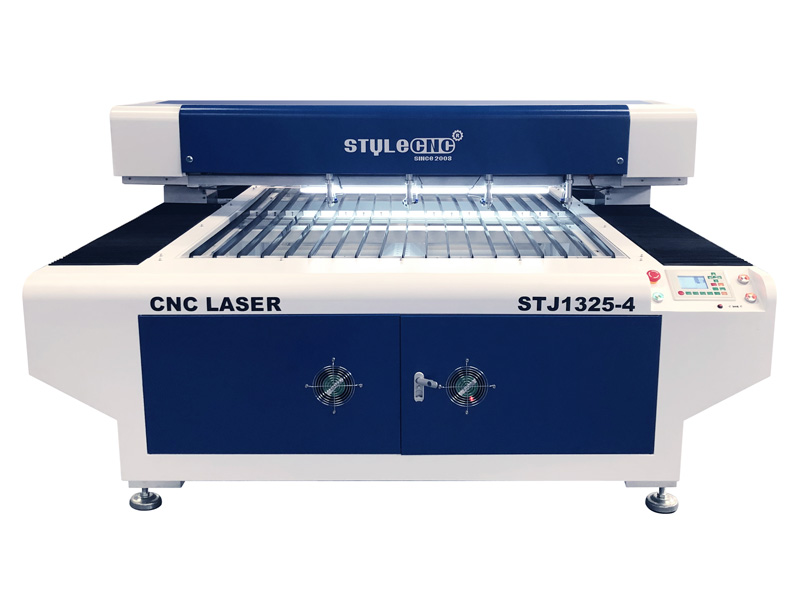

STJ1325-4 4x8 Industrial Laser Wood Cutting Machine

STJ1325-4

Features

STJ1325-4 industrial wood laser cutter is a laser wood cutting system with 4x8 (48" x 96") working table for MDF and plywood with four laser heads, which can cut four parts at the same time. Lens and mirrors are from USA with long lifespan. Double exhaust fans are used to clean the laser-cut chippings. PMI square linear guide rails on X/Y axis will make the laser cuts stably and precisely. Blade working table is used for hard materials. LCD Screen + USB port + Offline Control will make the machine easy to use.

Costs

The 4x8 industrial laser wood cutter is priced from $8,400, and up to $20,000 based on different features.

Pros

• Four laser cutting heads working on four projects with the same design.

• RECI CO2 laser tube with over 10,000 hours service life.

• Stepper motor and drivers transmission.

• It can cut the 4x8 full sheet plywood or MDF.

Cons

• It is not available to cut metal materials.

STJ1325 4x8 Industrial Laser Foam Cutting Machine

STJ1325

Features

STJ1325 industrial foam laser cutter is a type of 4x8 automatic foam cutting system with CNC controller for EPS foam, EVA foam, XPS foam, Styrofoam, PE foam in packaging, case making, insert making, mold making, lettering, and flooring. It can also cut rubber to make gasket.

Costs

The 4x8 industrial laser foam cutter costs minimum $6,800, and maximum $11,800 according different configurations.

Pros

• Constant light path system to do precision laser-cut foam.

• HIWIN square guide rails to ensure the machine working with high speed and precision.

Cons

• Laser cutting foam releases potentially harmful and toxic gases, and these emissions require air pollution control equipment, adding to the cost.

STJ1390-2 Industrial Laser Paper Cutting Machine

STJ1390-2

Features

STJ1390-2 industrial paper laser cutter is a CO2 laser cutting system with dual head to cut paper and cardboard for art, craft, invitation, model, sculpture, storage, and box. It is widely used in decorations, artwork, gifts, advertising, packaging, and printing. The wheels make it portable and easy to move, Blade table or Honeycomb table for option to fit different applications.

Costs

The affordable industrial laser paper cutter has the cheapest price of $3,800, and up to $6,500 with best budget.

Pros

• Two laser cutting heads work for double projects at the same time.

• USB offline controller will make the machine laser-cut faster and convenient.

• Automated up-down table is optional for higher and thicker materials.

Cons

• The table size is only 1300mm x 900mm.

• If the laser power is too high, it will cause the paper to burn.

ST-FC3015C 5x10 Industrial Sheet Metal Laser Cutter

ST-FC3015C

Features

ST-FC3015C industrial laser sheet metal cutter is a professional CNC metal cutting system with 5x10 table size. The professional typesetting and nesting software is highly integrated with the professional laser cutting system. It has the functions of graphic intelligent typesetting, automatic edge finding cutting and sharp corner smoothing processing, which can realize high-speed blasting perforation and high-speed scanning and cutting of array graphics. It is mainly used for fast cutting of carbon steel, stainless steel, aluminum alloy, titanium alloy, galvanized sheet, galvanized sheet, brass, copper and other metal materials.

Costs

The industrial sheet metal laser cutter costs from $31,500 to $73,800 based on different table sizes, laser generator brands and powers.

Pros

• The machine adopts gantry type double rack and pinion, double servo motor transmission, high torque and high inertia output, which effectively improves the manufacturing efficiency.

• The equipment has functions of power failure memory, fallback cutting, fault automatic alarm, emergency shutdown, fault content automatic display.

• The laser cutting head is equipped with automatic focusing function, which greatly shortens the perforation time compared with ordinary cutting heads, and is especially suitable for high-speed cutting of thicker sheet metals.

Cons

• Because the fiber cutting seam is very thin, the gas consumption is huge (especially when cutting with nitrogen).

ST-FC60M Industrial Laser Tube Cutting Machine

ST-FC60M

Features

ST-FC60M industrial laser tube cutter adopts CypTube CNC tube cutting software based on Windows operating system, a special platform for laser tube cutting machines, and integrates special function modules for laser cutting control. It has powerful functions of good man-machine interface and simple operation. Professional tube cutting programming software is one of the core technologies for CNC pipe cutting machines to achieve full-time and high-efficiency cutting, and is the fundamental guarantee for effectively saving materials and improving working efficiency. Capacitive fiber laser cutting head has high sensing accuracy, sensitive response, and the most stable and reliable performance. The unique custody device keeps the pipe in contact with the surface while the pipe is being fed and rotated. The supporting force is set according to the pipe specification to ensure effective support, prevent the pipe from sagging, and reduce the axis swing when the pipe rotates.

Costs

The industrial laser tube cutting system has a price range from $45,500 to $80,000 according to different configurations.

Pros

• The fully automatic whole bundle feeding function reduces the number of operators and improves the processing efficiency.

• The tube section automatic identification system can mix and feed a variety of tubes, automatically prompt the tube type, automatically retrieve the process library, and prompt the available processing programs.

• A complete cutting parameter library and a user-friendly parameter interface are provided. According to the type of pipe, the "one-click setting" cutting process can be realized, and the laser cutting parameters can also be modified in real time in the interface.

• The high-precision servo proportional valve can precisely control the gas pressure of the cutting auxiliary gas and the clamping force of the chuck to achieve the best cutting effect.

• The linear positioning speed of the pipe can reach 100m/min, and the rotational positioning speed can reach 120m/min.

Cons

• It can only be used to cut metal pipes, excluding sheet metal.

ST-FC3015LR 5x10 Industrial Sheet Metal & Tube Laser Cutting Machine

ST-FC3015LR

Features

ST-FC3015LR 5x10 industrial laser cutting machine is a multifunctional laser sheet metal & tube cutting system, which adopts gantry type double rack and pinion, double servo motor transmission, high torque and high inertia output, which can effectively improve the working efficiency. The machine bed frame is precision machined by a large-scale gantry machining center, and annealed in a large gas-fired trolley-type heat treatment furnace to eliminate the internal stress of the welding bed to the greatest extent, so that the equipment can achieve higher precision and higher stability.

Costs

The multi-purpose 5x10 industrial laser cutter for sheet metal & tube is priced from $42,500 to $78,500 due to different features.

Pros

• The laser cutting gun is equipped with automatic focusing function, which greatly shortens the perforation time compared with ordinary cutting heads, and is especially suitable for high-speed cutting of thicker sheet metals.

• The professional laser cutting system is compatible with the cutting process of sheet metals and pipes, and has the functions of graphic intelligent layout, automatic edge-finding and positioning of the pipe center and sharp corner smoothing.

• The machine is equipped with a pneumatic self-centering chuck, it can realize symmetrical independent double-action clamping, and the clamping process does not require manual intervention and adjustment.

• The machine is equipped with universal ball auxiliary feeding device.

Cons

• Due to the short wavelength of fiber laser, the damage to the human body, especially the eyes is great. For safety reasons, fiber laser processing requires a fully enclosed environment and professional protective glasses.

ST-18R 3D Industrial Laser Cutting Robot for Metal Fabrication

ST-18R

Features

ST-18R industrial laser cutting robot adopts automatic robot motion technology, equipped with professional high-precision laser gun, stable laser output power, large cutting format, can perform 2D/3D precise cutting of sheet metal and metal tube, equipped with LCD screen, offline CNC system, the operation is more convenient. The industrial laser metal cutting robot is suitable for stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel sheet, nickel-titanium alloy, inconel, aluminum, aluminum alloy, titanium alloy, copper and other metal materials. It is widely used in aerospace, automobile and ship, machinery manufacturing, elevator manufacturing, advertising production, household appliance manufacturing, medical equipment, hardware, decoration, metal external processing services and other manufacturing industries.

Costs

The 3D industrial laser cutting robot has a price range from $49,000 to $83,500 based on different robot brands and laser powers.

Pros

• Combination of ABB industrial robot and fiber laser cutting technology.

• 6-axis co-ordination makes the robot with a large cutting area.

• The robotic arm can be controlled via a handheld terminal.

Cons

• The sales price is higher.

• It can only cut metals, and non-metallic materials are not available.

ST-FC1325LC 4x8 CO2 & Fiber Hybrid Laser Cutting Machine for Metal & Nonmetal

ST-FC1325LC

Features

ST-FC1325LC industrial laser cutting machine is a hybrid CO2 & fiber laser cutting system to cut metals (stainless steel, carbon steel, aluminum, brass, copper, titanium, iron, alloy) with 1000W Raycus fiber laser generator, and cut non-metal materials (wood, MDF, plywood, acrylic, plastic, fabric, and leather) with RECI 150W CO2 laser tube all in one machine.

Costs

The 4x8 industrial laser cutter is priced from $19,800 to $32,500 based on different laser generator brands and laser powers.

Pros

• It has ability to cut both metals and nonmetals.

• Delta servo motor with single ball screw driving system to make precision cut.

• Au3tech CNC control system and software with automatic nesting to save materials and costs.

Cons

• It can only be used to cut sheets, excluding pipes.

• The maximum thickness of laser-cut sheet metal up to 10mm.

Summary

In short, whether you want to buy a laser cutting machine for industrial mass production or add it to your assembly line, the 9 best industrial laser cutters will meet your industrial manufacturing requirements.