Shipped well packaged and showed up with everything in good condition with easy to follow instructions. Easy to assemble. Well built. Very sturdy with heavy duty structure. In addition, this kit came with a full set of router bits of different sizes to use. Overall, it's a great CNC router with four rotary axes for 3D woodworking.

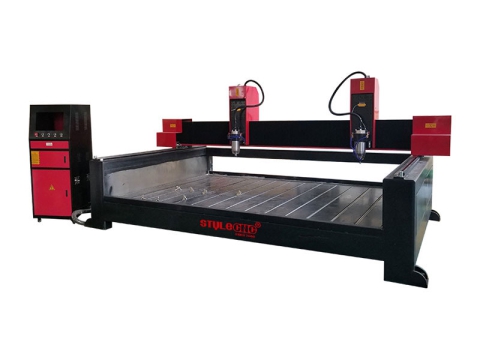

Affordable 3D CNC Router Machine with Multi 4th Rotary Axes

Affordable 3D CNC router machine with four 4th rotary axes is used for 3D carving & cutting in furniture mass production, 3D sculptures, and complex artworks. Now the multi 4th axis 3D CNC machine for sale at an affordable price.

- Brand - STYLECNC

- Model - STM2015

- Maker - Jinan Style Machinery Co., Ltd.

- Table Size - 1500mm x 200mm

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

The multi-4th rotary axes 3D CNC router machine is a specialist in carving, cutting, and shaping different materials into intricate 3D designs. As opposed to the standard CNC routers, which work on three axes linearly-that is, X-axis, Y-axis, and Z-axis-this machine has one additional rotary axis to rotate the material during its operation process. This adds to its versatility, enabling it to make detailed cylindrical and spherical objects.

With this addition, a 4th rotary axis makes them very ideal for complex projects. This addition will give them great accuracy on carving, especially for curved surfaces like columns, sculptures, and cylindrical objects. The industries where this feature can be used are furniture design, architectural modeling, and custom making of pieces of decoration. These machines work with wood, plastic, and some types of metal.

In general, a 3D CNC router with a 4th rotary axis will provide additional functionality and enlarged possibilities of design. This is a perfect choice for a business or hobbyist looking to make complex, high-quality 3D projects efficiently and accurately.

3D CNC Router Machine Advantages

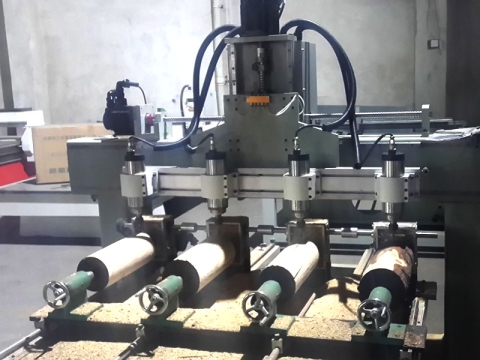

1. Multi heads can work at the same time to improve the same design engraving efficiency.

2. Multi heads can also work alone, and control the machine heads independently.

3. Multi-head CNC routers can use only one head to process and increase the working area.

4. Heads amounts and working area can be changed according to client's requests.

5. Four rotaries and four heads, which can work at the same time or independently.

3D CNC Router Machine Features

1. All machine heads can work at the same time, and they can also work alone, with good coherence and high quality when batch machining.

2. The lathe bed adopts a strong welded steel tube to avoid distortion.

3. Well-compatibility in software: all kinds of 3D carving.

4. More precise positioning accuracy.

5. It is an economical CNC machine.

6. The machine adopts a Taiwan double nut ball and an imported square guide rail.

7. Gantry movement, long time use without distortion.

8. We can make multi-head CNC machines and any working size according to your requirements.

Technical Parameters of 3D CNC Router Machine

| Model | STM2015 | |

| Rotary axis max diameter | 200mm | |

| Rotary axis max length | 1500mm | |

| Guide rail system | X,Y,Z axis | Linear square guide rail from Taiwan |

| Spindle | Power | 2.2kw |

| Rotating Speed | 0-24000 rpm (Optional air-cooling spindle with 18000 rpm) | |

| Cooling Type | Water cooling type | |

| Origin | China | |

| Collet diameter | 3/4/6/12.7mm | |

| About drive systems | X,Y,Z axis | stepper motor |

| Servo motor and driver | Panasonic/Yaskawa (optional) | |

| Dust collector system | Power | 3.0kw |

| Machine body | Square tube | |

| Control System | Ncstudio control system | |

| Built-in memory | 128 M | |

| Compatible file formats | G code, *.u00, *.mmg, *.plt . | |

| Compatible CAD/CAM Software | Ucancam / Type3 / ArtCAM | |

| Working Voltage | AC380V 50Hz | |

| Precision | 0.005mm | |

| Work-holding devices | by fixture | |

| Interface type | USB | |

| Cutting thickness of material | Depends on the materials | |

| Head | 4 heads | |

| Rotary | 4 Rotaries | |

3D CNC Router Machine Applications

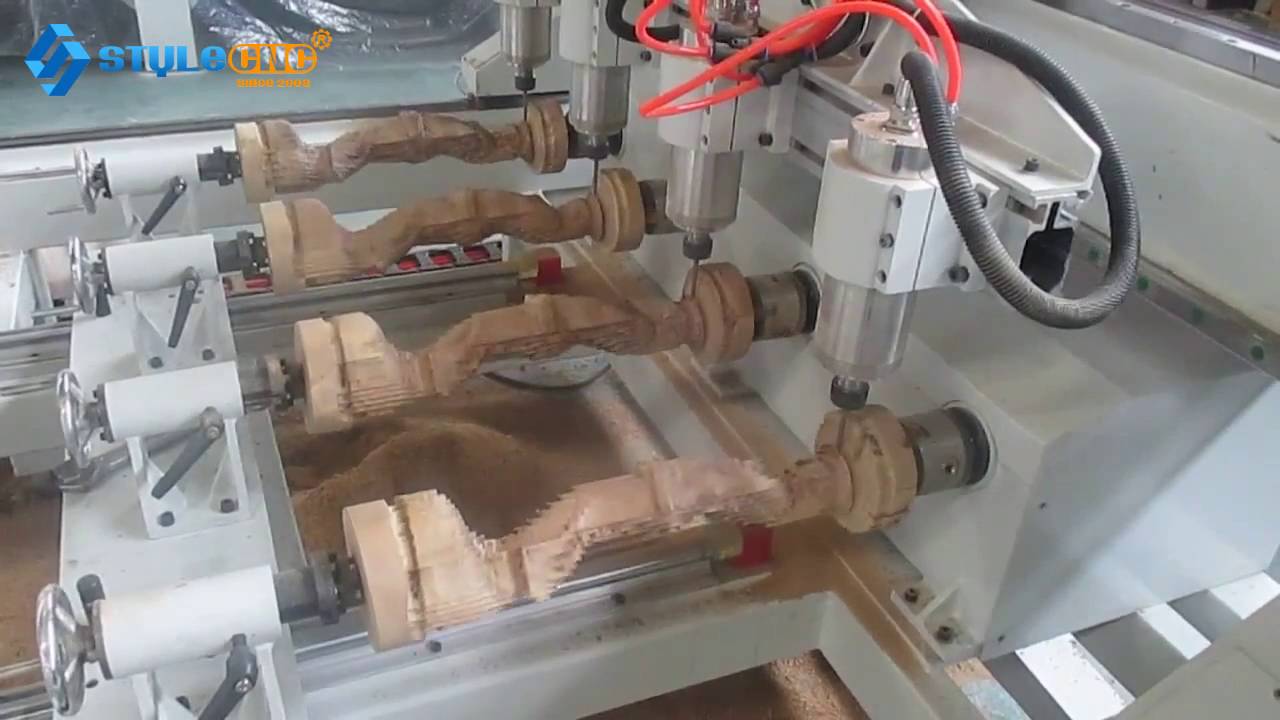

The 3D CNC carving machine is very suitable for furniture bulk production such as desk legs, stair handrails, and other column or cylinder products.

The 3D cylinder engraving machine can process 3D sculptures and complex artworks, it can easily process 360-degree human bodies, Buddhist statues, sculptures, artworks, furniture products such as desk legs, stair handrails, and so on.

3D Carving CNC Router Machine Projects

3D Carving CNC Router Machine Package

Four heads 3D CNC router inner package.

Four heads 3D CNC router outer package.

Why Choose a CNC Router with Multi 4th Rotary Axes for Complex Designs?

When equipping a CNC router with multi 4th rotary axes, there is a new dimension for design possibilities that it allows. It becomes the vital tool in intricate and detailed works that demand a degree of accuracy and versatility. This is the reason why such machines stand in opposition.

Enhanced Design Capabilities

With the 4th rotary axis, it is possible to make complex three-dimensional designs that are impossible with the standard CNC router. This allows for carving and shaping in curved or cylindrical surfaces, making it ideal for sculptures, pillars, and decorative pieces. Its advanced capabilities make it the favorite for professionals in industries related to architecture and fine art.

Increased Efficiency

The rotary axis minimizes manual adjustments during the machining process. By rotating the material automatically, the machine can work on multiple sides of an object without interruption, saving both time and effort. This streamlined process significantly boosts production speed without compromising quality.

More Precision

A CNC router with a 4th rotary axis ensures high accuracy, even down to the minute details. This makes it ideal for projects requiring consistency and fine craftsmanship, like making jewelry boxes or custom furniture elements. Every cut and carve is just as perfect as in the design specifications.

Material Versatility

These machines are compatible with a wide range of materials, from wood and plastic to foam and even some metals. This makes it possible to take on various projects, ranging from artistic creations to industrial applications. Be it softwood or heavy-duty aluminum, the machine provides excellent performance.

Cost-Effective for Complex Projects

Investing in a machine with a multi 4th rotary axis reduces the need for additional tools or labor for complex designs. Its multifunctionality streamlines the production process, making it a cost-effective solution in the long run. Over time, it lowers production costs while increasing output and overall efficiency.

Perfect for Creative Professionals

Artists, furniture designers, and architects can use this machine to bring intricate ideas to life. Its ability to execute detailed and precise designs makes it indispensable for creative industries. This machine bridges the gap between imagination and reality, enabling unique and sophisticated creations.

Installation and Setup Tips for 3D CNC Router Machines

Installation and proper setup of your 3D CNC router machine are quite crucial for one to have the best performance from the machine over a long period. The following tips will get you on a very good start toward realizing full potential with your machine on creative and industrial projects.

• Pick the Correct Location: Place the machine in a well-ventilated, clean, and spacious area for smooth operations and access. Ensure the surface is firm and level to avoid vibrating motions that will affect its precision.

• Check Electrical Requirements: Ensure the power is within the voltage and current limits of the machine. It is advisable to provide a dedicated circuit to the machine to avoid electrical malfunction and to protect the machine against power fluctuations.

• Assemble with Care: Next, follow the manufacturer's instructions and assemble the machine step by step to avoid overlooking or misplacing components. Also, use recommended tools to ensure that all parts are well fitted.

• Install Software Appropriately: Ensure to install compatible CNC software on your computer and connect it to the machine. Update drivers and firmware to the latest versions for better functionality and performance.

• Calibrate for Accuracy: Align the axes and tools for accuracy of operation. Test cuts on scrap materials to test the alignment of the machine.

• Training of the Operator: Understand yourself or your personnel with the controls and safety features of the machine. Proper training minimizes the risks of errors and improves productivity.

STYLECNC Service & Support

1. Guarantee & After-sale Service?

1.1. One-year warranty under normal use and we supply lifetime maintenance.

1.2. Technical support by Phone, Email, Skype, and WhatsApp around the clock.

1.3. Free Training to make sure you master the operation of the CNC Machine.

1.4. Friendly English Operation Manual, popular and easy to understand.

2. OEM Service Available?

2.1. Usually, we will manufacture the machine according to our regular design.

2.2. X, Y, Z Working Area could be customer-oriented designing.

2.3. Special configurations could be customer-oriented designing.

3. Delivery Time( Production Procedure)?

3.1. For a 3D CNC router machine with standard specifications, it is usually 10-15 days.

4. Payment Terms?

4.1. T/T in advance.

4.2. Alibaba.