Fiber & CO2 Laser Cutter Combo for Metal & Nonmetal

ST-FC1325LC laser cutter is a combined fiber laser and CO2 laser cutting system for metal and nonmetal fabrication, fiber laser cutting software and CO2 laser cutting software can be installed in one CNC system, which is easy to operate.

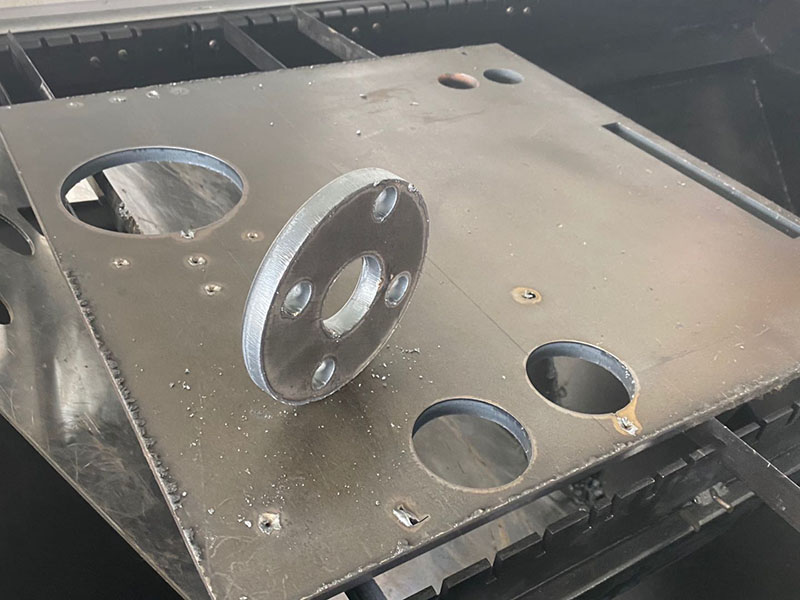

ST-FC1325LC mixed laser cutting machine combines with 1000W fiber laser cutting system and 150W CO2 laser cutting system, which can cut metal and non-metal materials by the one machine. The maximum cutting thickness is up to 10mm on carbon steel, 6mm on stainless steel, 3mm on aluminium plate, etc.

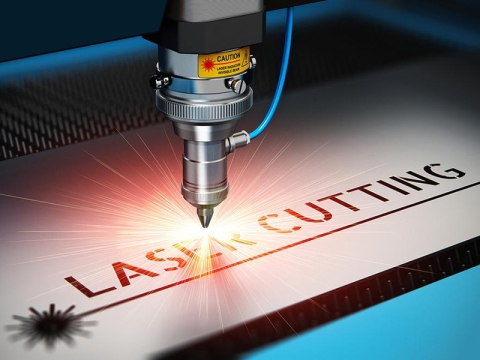

Laser cutting is a thermal cutting process used for sheet metal processing. The laser beam generated by the laser (resonator) is guided to the cutting head of the machine tool through a conductive fiber or mirror, and then focused through a lens to a small diameter area to concentrate the energy highly. The focused laser beam melts after contacting the plate.

Fiber Laser Cutter

Fiber laser is the most effective laser cutting method. The laser beam is generated in the active fiber, and then guided to the cutting head of the machine tool through the conductive fiber. Fiber lasers are much smaller than CO2 lasers and produce several times more power under the same power supply conditions. Fiber laser cutting machine is suitable for cutting metals from thin to thick, stainless steel, carbon steel, aluminum and non-ferrous metals (copper and brass).

CO2 Laser Cutter

The CO2 laser uses a mixed gas to generate the laser beam. The high voltage required in the laser is generated by the wear-free semiconductor excitation module. STYLECNC uses this module because it is smaller, more efficient, and more reliable than traditional solutions. CO2 laser technology is widely used in the cutting of different materials with different thicknesses.

Are you looking for such a combined laser cutter, please check details from:

ST-FC1325LC Combined Laser Cutting Machine

Share This Article With Others

Further Reading

2025-08-079 Min Read

Explore the best metal laser cutters for every need in 2025 - from home to commercial uses, from hobbyist to industrial makers, from entry-level to pro models.

2026-03-0317 Min Read

Are you planning to build your own laser cutting machine for hobbyists, or start a business to make money with it? Review this guide to learn how to DIY a laser cutter by yourself, and grow up to be an enviable professional maker.

2025-02-062 Min Read

2025 best laser engraver cutter software with paid & free versions include LaserCut, CypCut, CypOne, RDWorks, EZCAD, Laser GRBL, Inkscape, EzGraver, SolveSpace, LaserWeb, LightBurn, Adobe Illustrator, Corel Draw, AutoCAD, Archicad and some popular CAD/CAM software for laser cutter engraving machine.

2023-11-214 Min Read

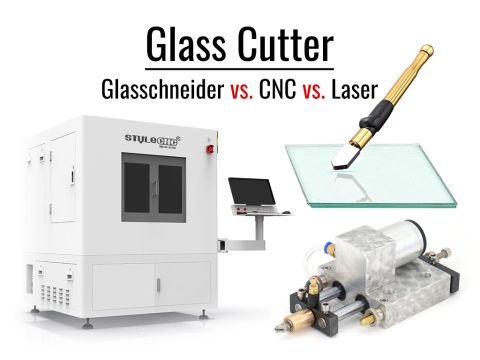

Glasschneider, CNC machine, laser cutter, which is better for mobile phone makers to cut smartphone glass (as well as tablet and laptop glass) such as Gorilla glass, Sapphire, Dragontrail glass to make personalized mobile cell phone screens, displays, front covers, rear panels, camera cover, filter, fingerprint identification sheet, prism?

2023-09-263 Min Read

As a beginner or operator, you need to learn the 3 tips you should know before starting a laser cutting system, the 12 steps to learn how to use a laser cutter, the 12 precautions for a laser machine.

2024-02-286 Min Read

In this article, you will get the laser cutting basics, including definition, working principle, types, features, applications, and trends in future.