Why Choosing the Right Stepper Motor is Important

A CNC machine's ability to operate smoothly and precisely depends on the choice of stepper motor. The motor controls the movement of parts, and any mismatch can lead to positioning errors or poor-quality results. A motor that is too weak may slip, causing misaligned cuts and mechanical issues.

Different CNC tasks require specific torque levels. Using a motor with insufficient torque can prevent the machine from handling heavier parts or maintaining speed. On the other hand, an overpowered motor may waste energy and increase running costs, reducing efficiency. Finding the right balance ensures smooth performance without excess power consumption.

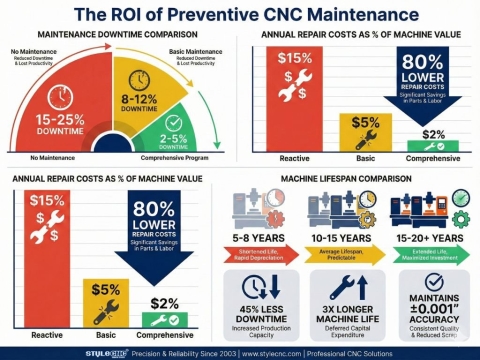

It has also been pointed out that selecting a suitable motor guarantees the sustainability of your machine in the long run. A motor with low performance may wear out more quickly, requiring more frequent repairs. You can save time and money by using a well-chosen motor, which also minimizes maintenance expenses and downtime. You would not have these issues and your CNC machine would run smoothly if you selected the proper motor for it.

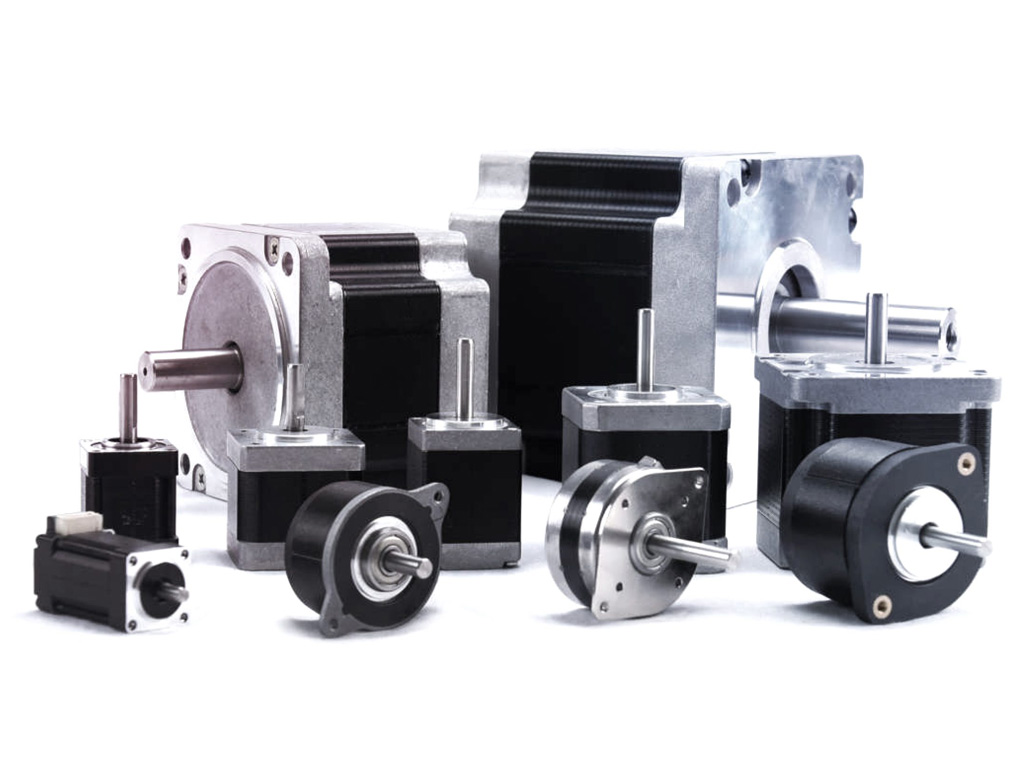

Types of Stepper Motors Used in CNC Machines

CNC machines use a variety of stepper motor types, each with special characteristics appropriate for a particular purpose. Unipolar, bipolar, and hybrid stepper motors are the three most popular varieties. It is easier to select the appropriate one for your CNC application when you are aware of their distinctions.

Unipolar Stepper Motors

Unipolar motors have a simpler wiring structure with a center tap on each coil, making them easy to control. They use fewer electronic components, which reduces cost. However, they generate less torque compared to other stepper motor types. These motors are ideal for low-power CNC applications, such as laser engraving or light-duty 3D printing.

Bipolar Stepper Motors

Bipolar stepper motors provide higher torque by utilizing the full winding of each coil. They require more complex wiring and control systems but are more efficient in delivering power. Bipolar motors are well-suited for tasks that demand more strength, such as milling, drilling, or metal engraving. They are a popular choice for mid-range CNC machines that need reliable and precise movement.

Hybrid Stepper Motors

Hybrid stepper motors combine the best aspects of bipolar and unipolar design to produce exceptional torque and accuracy. They are the most chosen alternative for CNC machines because of their outstanding performance on difficult tasks. Hybrid motors are used in applications that need accuracy, such as precision milling, 3D carving, and high-speed cutting. Because of their adaptability and seamless operation, these motors are the greatest choice for both specialists and hobbyists.

How to Choose a Stepper Motor for a CNC Machine?

Choosing the right stepper motor for your CNC machine ensures smooth and precise performance. A stepper motor provides the needed torque to move parts accurately. Selecting the correct motor based on your machine's torque requirements helps avoid issues down the line. Follow these steps to make the right choice.

Step 1: Selection of Stepper Motor Torque

The holding torque of a stepper motor is similar to what is called "power" by a conventional motor. Of course, there are essential differences. The physical structure of the stepping motor is completely different from AC and DC motors, and the output power of the motor is variable.

Which type of motor is usually selected according to the required torque (that is, the torque of the object to be driven)?

As a rule, if the torque does not exceed 0.8N.m, a choice between 20, 28, 35, 39, 42 (diameter or squareness of motor body, unit: mm) would be considered. If the torque is approximately 1N.m, the motors of type 57 are to be favored. When the torque is quite a few N.m or even higher, one should use the stepper motors of 86, 110, 130, etc. specifications.

Step 2: Selection of Stepper Motor Speed

Aside from the above parameters, the motor speed requirements should be determined as well. This is since as speed increases the output torque of the motor declines. Consequently, low speeds (a couple of hundred revolutions per minute or below) allow for more torque output, while high speeds (1000 rpm to 9000 rpm) do not allow for a lot of torque output. Naturally, some applications require high-speed thresholds for motors, therefore other parameters of the stepping motor, such as the coil resistance and the inductance need to be examined as well.

To measure. Choose a motor with a slightly smaller inductance, as a high-speed motor, you can get a larger output torque. Conversely, when low speed and high torque are required, it is better to choose an inductance of more than ten or tens of mH and a larger resistance.

Step 3: Selection of No-load Starting Frequency

The no-load starting frequency of the stepping motor is usually called "no-load starting frequency". This is an important indicator for choosing a motor. If it is required to start and stop frequently in an instant, and the speed is around 1000 rpm (or higher), usually "accelerated start" is required.

If a direct start is required to achieve high-speed operation, it is best to choose a reactive or permanent magnet motor. The "idling frequency" of these motors is relatively high.

Step 4: Phase Number Selection

The selection of the number of phases of the stepper motor, this content, many customers pay little attention to it, and most of them buy it casually. Motors with different phase numbers have different working effects. The more the number of phases, the smaller the step angle can be made, and the vibration during work is relatively

smaller. In most occasions, two-phase motors are used more. In a working environment of high speed and high torque, it is more practical to choose a three-phase stepping motor.

Step 5: Use the Environment to Select

Select special stepper motors according to the environment in which the stepper motors are used, which can be waterproof and oil-proof, and can be used in some special occasions. For example, underwater robots need water motors. For special-purpose motors, it is necessary to select them in a targeted manner.

Step 6: Special Specifications (if Required)

For stepping motors with special specifications, please communicate with us, and process and order within the range allowed by technology. For example, the diameter, length, extension direction, etc. of the output shaft.

Step 7: If Necessary, It is best to Further Communicate and Confirm the Model With the Technical Engineer of the Manufacturer

If necessary, it is best to communicate further with the technical engineer of the manufacturer, to confirm whether the stepper motor you want to choose can meet all the indicators you require.

Tips for Making the Right Choice for Your CNC Machine

Selecting the appropriate stepper motor can have a significant impact on its longevity, accuracy, and performance. This is a list of important things to think about before choosing.

• Determine Torque Requirements: Know how much force your machine needs to move smoothly. Choose a motor with enough holding torque to prevent slipping or missed steps.

• Match Motor Size to Your Application: Use smaller motors (e.g., NEMA 17 or NEMA 23) for lightweight tasks like engraving. For heavy workloads, go with larger motors (e.g., NEMA 34 or NEMA 42).

• Balance Speed and Precision: Choose a motor based on the priority of your task—speed or accuracy. For engraving or detailed cuts, precision is more important than high speed.

• Ensure Compatibility with Drivers and Controllers: Verify that your motor matches the voltage and current ratings of the driver. Mismatched components can cause system instability or failures.

• Consider the Operating Environment: If your machine operates in dusty or hot areas, pick a motor with protective features. Some motors are designed to withstand harsh conditions better than others.

• Plan for Future Expansion: Think ahead if you plan to upgrade your machine. Choosing a motor with extra capacity now can save you money on replacements later.