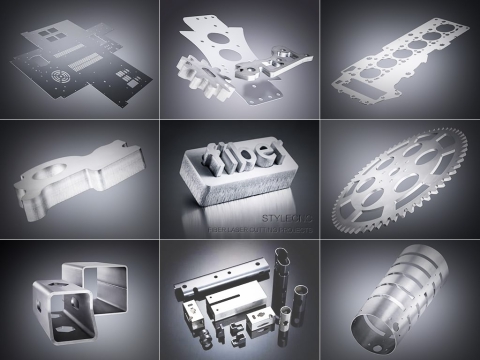

A fiber laser cutter features with high cutting precision, fast cutting speed, and low cost, which is the most professional cutting tool in the metal fabrication. When buying or assembling by yourself, you should know what are the components of a fiber laser cutting machine?

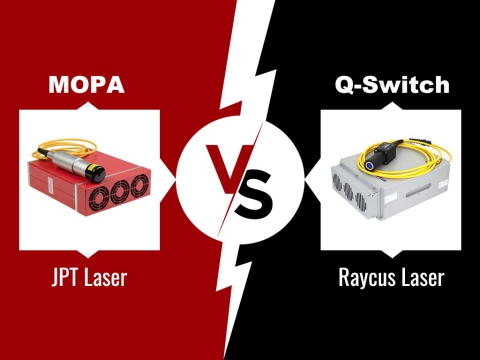

Fiber Laser Generator

Laser generator is the core "power source" of laser equipment, just like car engine, it is also an expensive component in fiber laser cutting system. At present, the popular brands of fiber laser generators on the market include IPG, Raycus, JPT, and MAX.

Fiber Laser Cutting Head

The cutting head is the laser output device of the fiber laser cutting machine, which consists of a nozzle, a focus lens and a focus tracking system. The cutting head of the laser cutting machine will travel according to the set cutting track, but the height of the laser cutting head needs to be adjusted and controlled under different materials, different thicknesses, and different cutting methods.

The cutting head is composed of a nozzle, a focusing lens and a focusing tracking system.

Cutting Nozzle

There are three common types of nozzles on the market: parallel, converging and conical.

Focusing Lens

Focus the energy of the laser beam and form a high energy density spot. The medium and long focusing lens is suitable for thick plate cutting, and has low requirements on the spacing stability of the tracking system. The short focusing lens is only suitable for thin plate cutting, which requires high spacing stability of the tracking system and greatly reduces the laser output power requirements.

Focus Tracking System

The focus tracking system is generally composed of a focus cutting head and a tracking sensor system. The cutting head consists of light guide focusing, water cooling, air blowing and mechanical adjustment parts. The sensor is composed of sensing element and amplification control part. The tracking system is completely different according to the different sensing elements. Here, there are mainly two forms of tracking system, one is the capacitive sensor tracking system, also known as the non-contact tracking system. The other is an inductive sensor tracking system, also known as a contact tracking system.

Laser Beam Delivery Components

The main component of the laser beam delivery assembly is the refractive mirror, which is used to direct the laser light in the desired direction. The reflector is usually protected by a protective cover, and a clean positive pressure protective gas is introduced to protect the lens from contamination.

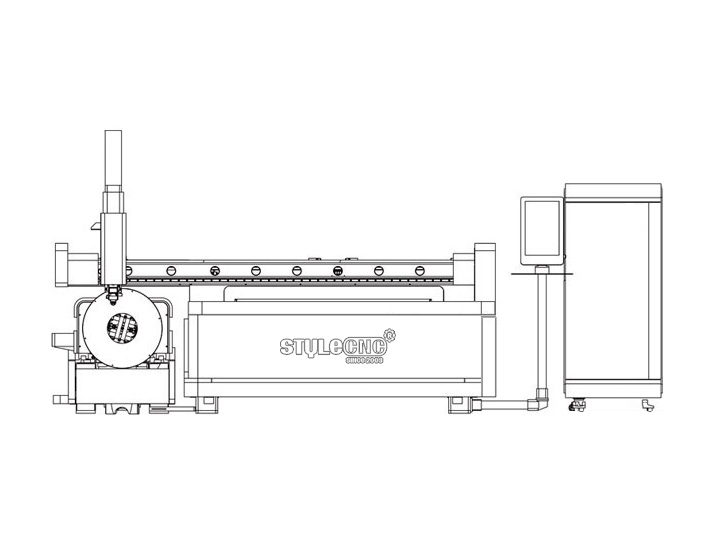

CNC Laser Cutting System

The control system is the dominant operating system of the fiber laser cutting machine, which controls the cutter to realize the movement of the X, Y, and Z axis, and also controls the output power of the laser. Its quality determines the stability of the operation performance of the fiber laser cutting system Through software control, the cutting effect can be improved.

Motor Drive

The motor of the laser cutting machine is the core component of the motion system. The performance of the motor directly affects the effect of product processing and production efficiency. At present, the commonly used motors include stepper motors and servo motors. The configuration is based on the type of industry and product type of the cutting object.

Stepping Motor

High starting speed, sensitive response, suitable for cutting with low requirements. The price is lower. There are many brands of stepper motors with different performances.

Servo Motor

High movement, stable movement, high load, stable performance, smooth edges of processed products, high cutting speed, high price, suitable for industries and products with higher cutting requirements.

Bed Frame

Metal laser cutters with fiber laser source have very high requirements for machine stability. At present, the mainstream machine frames on the market include gantry type, cantilever type, beam type, etc. Different machine frames have different functions. For example, beam type machine frames are mainly used for material cutting of large manufacturers. There are also models for specific fields, such as three-dimensional fiber laser cutting, which is mainly used in the automotive industry.

Water Chiller

The function of the chiller is to cool lasers, spindles and other devices. The laser is a device that converts electrical energy into light energy, and the cooling water takes away the excess heat to maintain the normal operation of the laser generator. Most of the current chillers have been equipped with input and output control equipment switches, with cooling water flow, high and low temperature alarm functions, and the equipment performance is more stable.

Stabilizer

A device connected between lasers, CNC machines and power supply systems. It mainly plays the role of preventing external grid interference and stabilizing the voltage, so as to ensure the normal operation of the machine.

Air Supply System

The air supply system of the fiber laser cutting machine includes air source, filter device and pipeline. The gas sources include bottled gas, liquefied gas, and compressed air.

Dust Collector

The dust collector extracts the smoke and dust generated during laser cutting, and performs filtering treatment, so that the exhaust gas discharge meets the environmental protection standards and will not cause pollution to the environment, so as to achieve the purpose of environmentally friendly production. At present, the country has strict environmental protection requirements, and the dust collector system is also an essential laser equipment component.