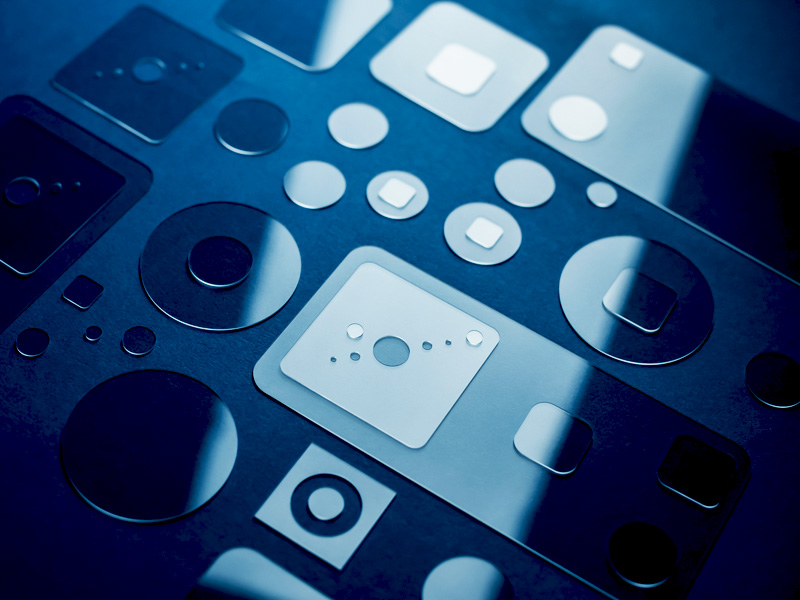

You will meet three most common glass cutting tools to make personalized glass parts and accessories, including Glasschneider, CNC machine, laser cutter, which one is better for mobile phone makers and repair shops to cut smartphone glass such as Gorilla glass, Sapphire, Dragontrail glass to make personalized mobile cell phone screens, displays, front covers, rear panels, camera cover, filter, fingerprint identification sheet, prism? This article lists and compares the pros and cons of three different glass cutters to help you decide which one to buy and use.

The emergence of smart phones has greatly changed people's lifestyles, and the continuous improvement of people's living standards has also put forward higher requirements for smart phones. In addition to the continuous upgrading of system, hardware and other functional configurations, the appearance of mobile phones has also become the focus of competition among mobile phone manufacturers. In the innovation process of appearance materials, glass materials are welcomed by makers due to their advantages such as changeable shapes, good impact resistance, and controllable costs, and have been more and more widely used in mobile cell phones manufacturing.

Although the glass material has many advantages, its fragility brings many difficulties to the processing process, such as cracks and rough edges. In addition, the special-shaped cutting of the earpiece, front camera, fingerprint sheet also puts forward higher requirements on the processing technology. How to solve the processing problems of glass materials and improve product yield has become a common goal in the mobile cell phone industry, and it is imminent to promote the innovation of glass cutting technology.

The listed below is a detailed comparison of three most common types of glass cutters used for custom smartphones, tablets and laptops.

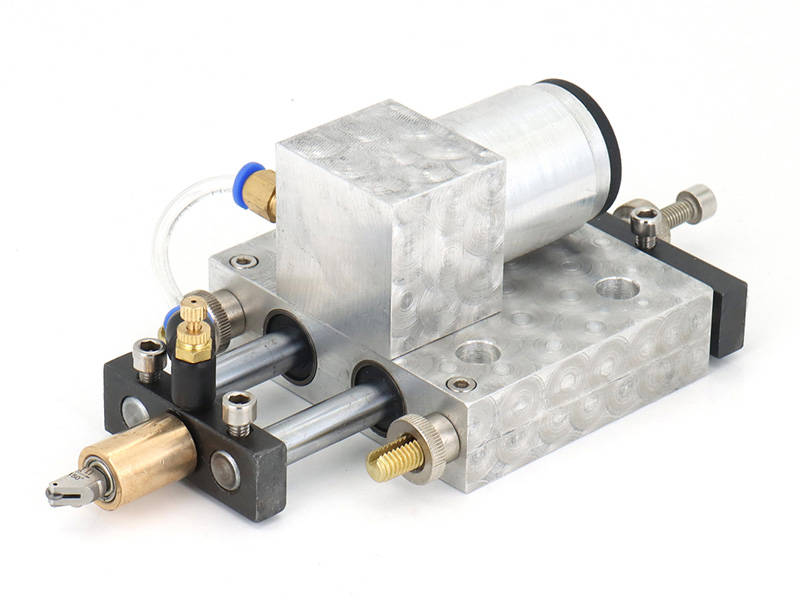

Handheld Glasschneider & CNC Glass Cutter

Traditional glass cutting tools include Glasschneider and CNC cutter. The glass cut by the Glasschneider has large chipping and rough edges, which will greatly affect the strength of the glass. Moreover, the yield rate of glass cut by the Glasschneider is low, and the material utilization rate is low. After cutting, post-processing of complicated processes is required. The speed and accuracy will be greatly reduced when the Glasschneider performs special-shaped cutting. Some special-shaped full screens cannot be cut by the Glasschneider because the corner is too small. The precision of CNC cutting is higher than that of Glasschneider, the precision is ≤30μm, and the edge chipping is about 40μm, smaller than that of Glasschneider. The disadvantage is that the speed is slow.

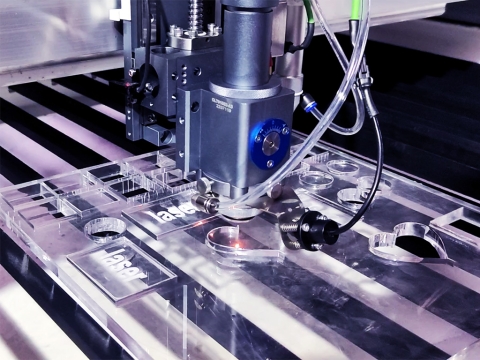

Ordinary Laser Glass Cutter

With the development of laser technology, laser has also appeared in glass cutting. The speed of laser glass cutting is fast, the precision is high, the incision has no burrs and is not limited by the shape, and the edge chipping is generally less than 80 μm.

Ordinary laser glass cutting is based on the ablation mechanism. The focused high-energy-density laser is used to melt or even gasify the glass, and the high-pressure auxiliary gas blows off the residual slag. Because the glass is fragile, the high-overlap ratio light spots will accumulate excessive heat on the glass and crack the glass. Therefore, the laser cannot use the high-overlap ratio light spots for one-time cutting. Usually, a vibrating mirror is used for high-speed scanning to cut the glass layer by layer. In addition, the general cutting speed is less than 1mm/s.

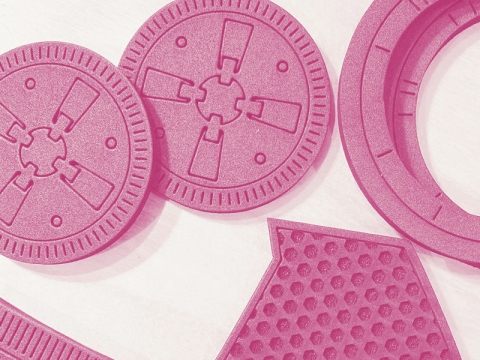

Ultrafast Laser Glass Cutting Machine

In recent years, ultrafast lasers (or ultrashort pulse lasers) have achieved rapid development, especially in the application of glass cutting. High, no micro-cracks, broken or fragments, high edge crack resistance, no need for secondary manufacturing costs such as washing, grinding, polishing, reducing costs and greatly improving workpiece yield and processing efficiency. STYLECNC's ultra-fast laser cutting machine has excellent performance in the processing of brittle materials. It can cut brittle materials better and faster, and further reduce the cost. At the same time, the laser is more stable and can support various scenarios.

The ultra-fast glass laser cutting system uses the processing method of galvanometer drilling, the thickness of the glass can be processed up to 1mm, the minimum diameter of the round hole can reach 60μm, the black edge is less than 30μm, and the chipping is less than 10μm.

The ultra-fast laser glass cutting machine can support micro-hole drilling, the minimum diameter of the round hole can reach 10 μm, and the edge chipping is less than 5 μm. The processing efficiency is extremely fast, and it has irreplaceable advantages in application scenarios such as semiconductor glass drilling and medical micro-channels.

The ultrafast laser power ranges from 10W, 20W, 30W, 50W, up to 70W, and the maximum single pulse energy can reach 1.5mJ, which can meet most of the needs of customers for infrared picosecond lasers.

The cutting frequency is from 10K-1000K, the roundness of the light spot can reach more than 90%, and the pulse stability is less than 2%. It can ensure that there is no pulse leakage during processing, and the dot size remains consistent. In the pulse train mode, the pulse energy is greater, and the intensity of a single sub-pulse can be adjusted to meet the different process needs of customers.

Ultrafast laser has unparalleled advantages in cutting various transparent and brittle materials, such as glass, sapphire, and full screen. Not only the cutting thickness range is wide, but also the cutting quality is good, no chipping, debris, easy to form micro-cracks, high bending strength, and can achieve any shape cutting without taper (straight line, curve, round hole and other shapes & contours).