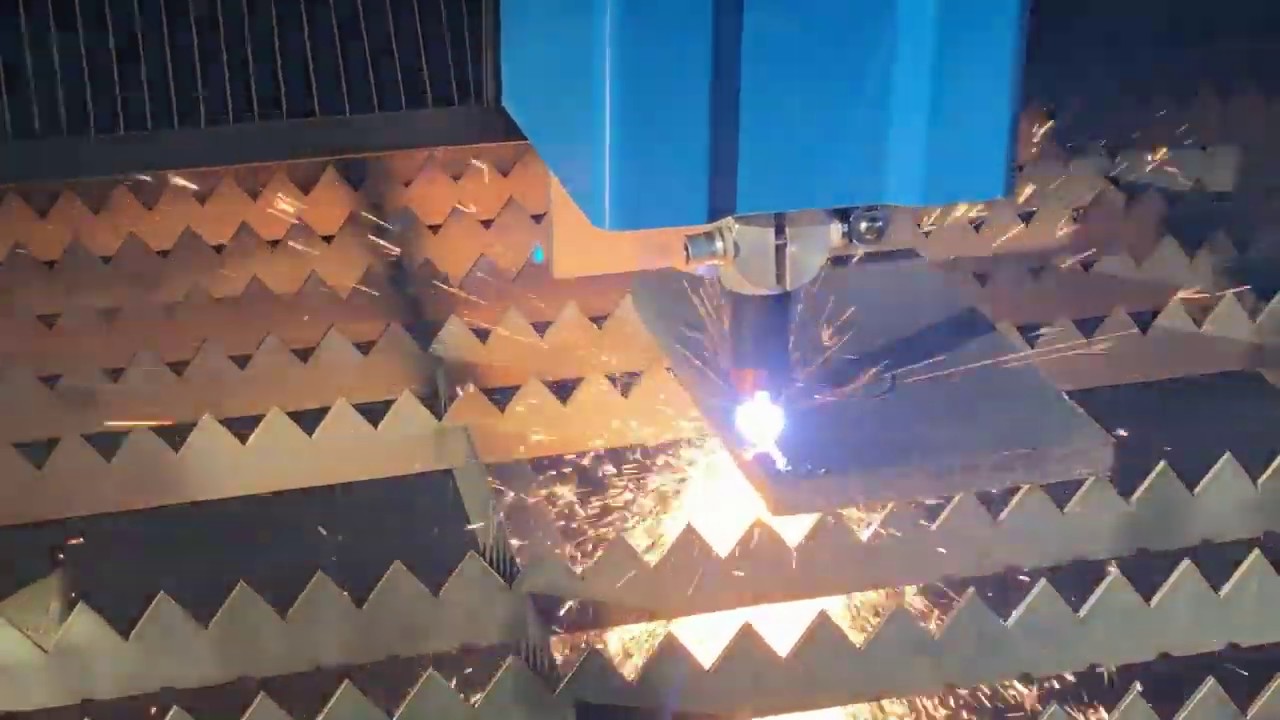

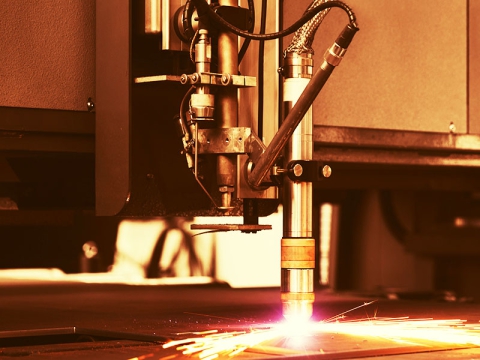

Plasma cutting is the use of high-speed air jets ejected from the nozzle at high temperature to ionize, thereby forming a conductor. When the current passes through, the conductive gas forms a high-temperature plasma arc. The heat of the arc locally melts (and evaporates) the metal at the cut of the workpiece, and a method of processing to remove the molten metal by the power of the high-speed plasma gas flow to form the cut. The slender and stable plasma arc formed by the annular gas flow technology ensures that any conductive metal can be cut smoothly and economically. One plasma generator and one torch can realize manual cutting. However, manual hand-held cutting has low efficiency, poor cutting accuracy, and poor cutting quality. For the cutting of complex graphics, the process is often cumbersome or powerless. In order to meet the needs of faster and higher quality mass production cutting, CNC plasma cutting equipment came into being. It is an inevitable requirement of modern industrial production. CNC plasma cutting is to provide an automatic digital control platform for plasma cutting machine. Combining the simple and easy-to-use CNC system and machine tool platform to realize the automation of plasma cutting, to meet the high efficiency and batch processing requirements of modern industrial production. CNC plasma cutting machine is divided into dry plasma, semi-dry plasma, underwater plasma; ordinary plasma, fine plasma, laser-like plasma according to the cutting quality.

The main applications of CNC plasma tables are: stainless steel, cast iron, copper, aluminum and other non-ferrous metal plates, etc., which are mainly used for plane cutting irregular graphics. In theory, as long as the graphics can be drawn with AUTOCAD, the cutting can be done 2 times the width of the plasma slit can not be cut.

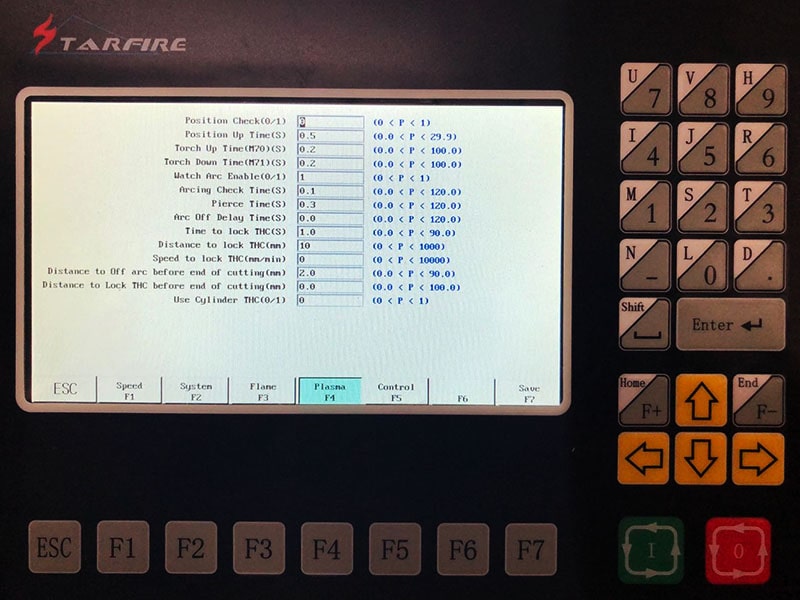

A complete CNC plasma cutting machine is mainly composed of plasma power supply, CNC system, plasma table and air supply device (air compressor). The plasma generator and its cutting torch group directly determine the cutting quality, the numerical control system and the machine tool directly determine the cutting accuracy, and the gas supply device directly affects the cutting quality, which is also a necessary condition for the plasma generator to work.