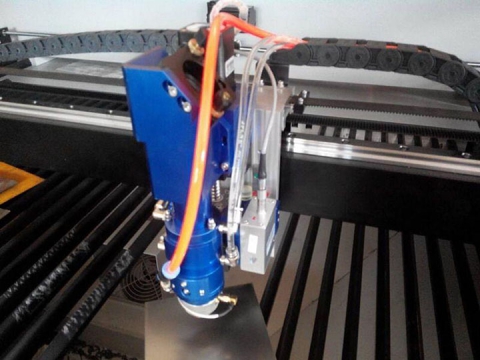

Laser deep engraving machines and laser shallow engraving machines are essentially fiber laser marking machines. The laser beams with very high energy pass through the surface of the material for evaporation so that deep material is exposed, representing exquisite patterns and texts clear and indelible characters.

Fiber laser engravers comes with deep focusing capabilities to deeply engrave on metals for seal engraving and mold making. The depth-of-engraving would correlate with aspects involving material's absorption itself against which a laser may go through an operation action in operation against the metal laser's powers and an influence action's time frame applied onto engraved material. More common is longer action associated with deep engraving.

The laser shallow engraver is also a commonly used laser marking system. Compared to the deep laser engraver, it doesn't require a deep focus. It is used in company logo engraving, food packaging identification codes, and all kinds of complex patterns on the surface of various metal and non-metal materials. The depth of engraving is automatically adjusted by the software.

Irrespective of whether it is the laser deep engraving system or the laser shallow engraving system, it compensates for the shortcomings of the traditional processing method that couldn't have been realized. The method non-contact processes, and markings are clear and long-lasting; it has a fast processing speed, high precision, and wide scope of application. It is also an essential soft machining tool in all walks of life today.

Applications of Laser Deep Engraving Machines

Laser deep engraving machines are powerful machinery developed for precision and durability in different industries. These machines excel in making permanent marks, intricate designs, and functional components. Their versatility makes them indispensable to businesses looking for high-quality engravings on various materials.

Industrial Mold Engraving

Laser deep engraving machines are widely used for marking and creating detailed impressions on industrial molds. These engravings are durable and withstand repeated use in high-pressure manufacturing environments.

Metal Stamping Dies

Ideal for producing stamps and dies with intricate patterns, these machines ensure high precision and accuracy. The engraved patterns can be used for creating consistent impressions on metals and other materials.

Jewelry and Decorative Art

Deep engraving could be one means for individualization of your jewelry or highly detailed and sharp designing. Besides, patterns could remain bright and visible through regular wear.

Automotive and Aerospace Components

These machines engrave serial numbers, part labels, and logos on metal components for traceability and meeting the standards of the industry. The durability of the engravings is very important for maintaining readability in harsh conditions.

Seal and Coin Production

Laser deep engraving is extensively used to create highly detailed seals and coins. These engravings are both functional and aesthetically pleasing, meeting strict quality requirements.

Medical Device Marking

In the medical field, laser deep engraving is used for marking instruments and implants with serial numbers or branding. The engravings are biocompatible and highly resistant to sterilization processes.

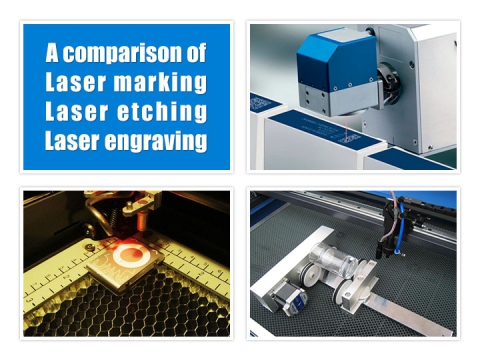

Deep vs. Shallow Laser Engraving: Key Differences

Understanding the differences between deep and shallow laser engraving is the first step in choosing the right technique for your project. While both techniques make use of the same technology-fiber laser marking-they serve different applications and give different results. Here's a detailed comparison to guide you.

| Aspect | Deep Laser Engraving | Shallow Laser Engraving |

|---|---|---|

| Engraving Depth | Penetrates the material surface deeply, exposing layers beneath for a clear, long-lasting impression. | Creates a lighter, surface-level engraving, ideal for intricate details and aesthetic purposes. |

| Applications | Suited for industrial tasks like mold engraving, metal stamping, and creating durable seals. | Ideal for marking company logos, identification codes, and decorative designs on various surfaces. |

| Materials | Works effectively on metals like steel, aluminum, and titanium that can withstand deep laser penetration. | Suitable for a broader range of materials, including metals and non-metals like plastic, leather, and wood. |

| Precision & Clarity | Offers high precision for functional components, ensuring durability under wear and tear. | Provides exceptional detail for intricate patterns and fine finishes without altering the material’s structure. |

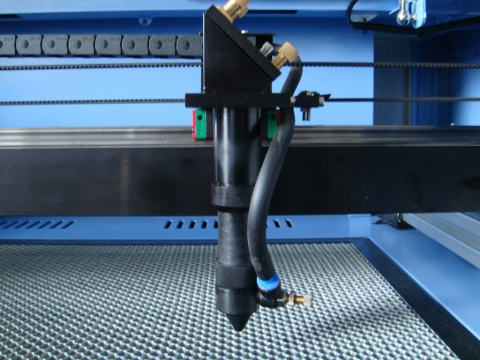

| Laser Focus | Requires a deep focus to achieve the desired depth, typically involving multiple passes. | Involves shallow focus with fewer passes, making it faster for simpler designs. |

| Processing Time | Longer due to the depth and multiple layers being engraved. | Quicker as it focuses on the surface without intense penetration. |

| Software Requirements | Uses advanced settings to control depth, power, and time for consistent results. | Relies on automated adjustments in the software for efficient shallow marking. |

Tips for Optimizing Engraving Depth and Speed

Achieving the perfect balance between engraving depth and speed is key to producing high-quality results efficiently. By fine-tuning your settings and understanding material characteristics, you can enhance the performance of your laser engraving machine and meet your project requirements effectively.

• Understand Material Properties: Different materials respond uniquely to laser engraving. Conduct a small test run to determine the optimal settings for depth and speed based on material hardness, reflectivity, and thermal conductivity.

• Adjust Laser Power Carefully: Higher laser power increases engraving depth but can slow down the process or cause material damage. Begin with moderate power settings and gradually adjust to achieve the desired results without compromising quality.

• Optimize Engraving Speed: Lower engraving speeds generally allow for deeper engraving but take longer. Experiment with speed settings to find the sweet spot where depth and efficiency are balanced.

• Use Multiple Passes for Precision: For deeper engravings, use multiple passes with moderate power rather than a single high-power pass. This approach minimizes material stress and ensures clean, detailed results.

• Maintain Focus Accuracy: Proper focusing of the laser is essential for achieving consistent depth. Ensure the focal length is correctly set based on your material’s thickness to avoid uneven engravings.

• Keep the Lens Clean: Dust and residue on the lens can reduce laser efficiency, impacting both speed and depth. Regular cleaning ensures the laser maintains optimal performance.

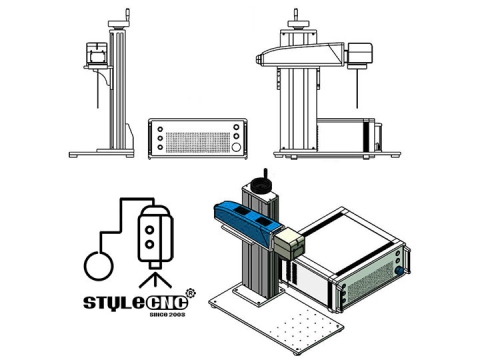

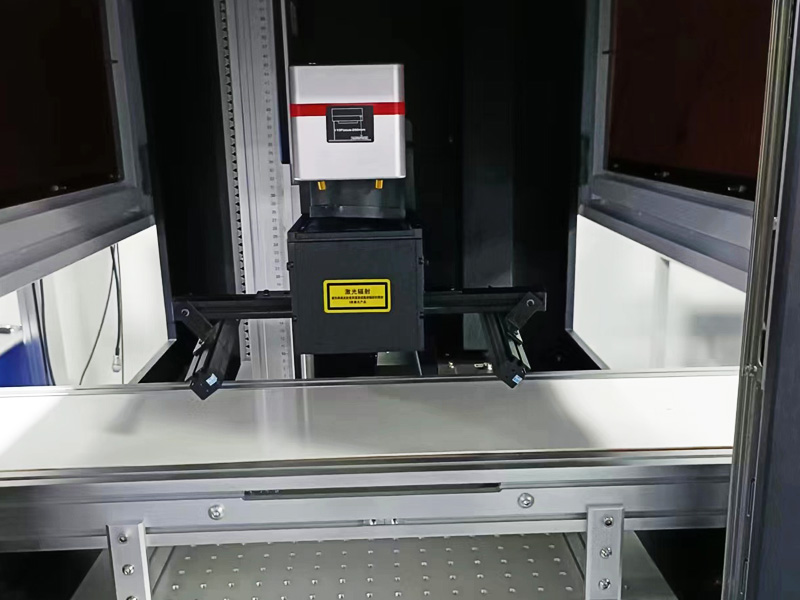

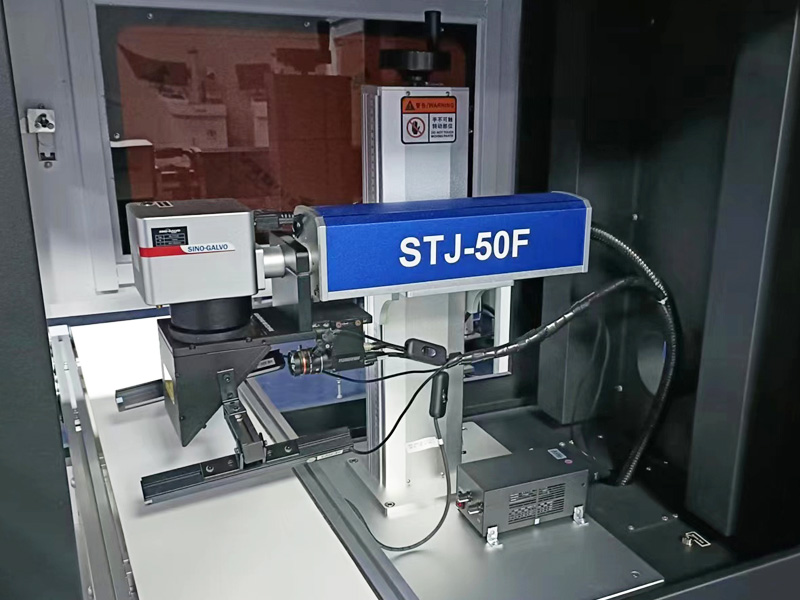

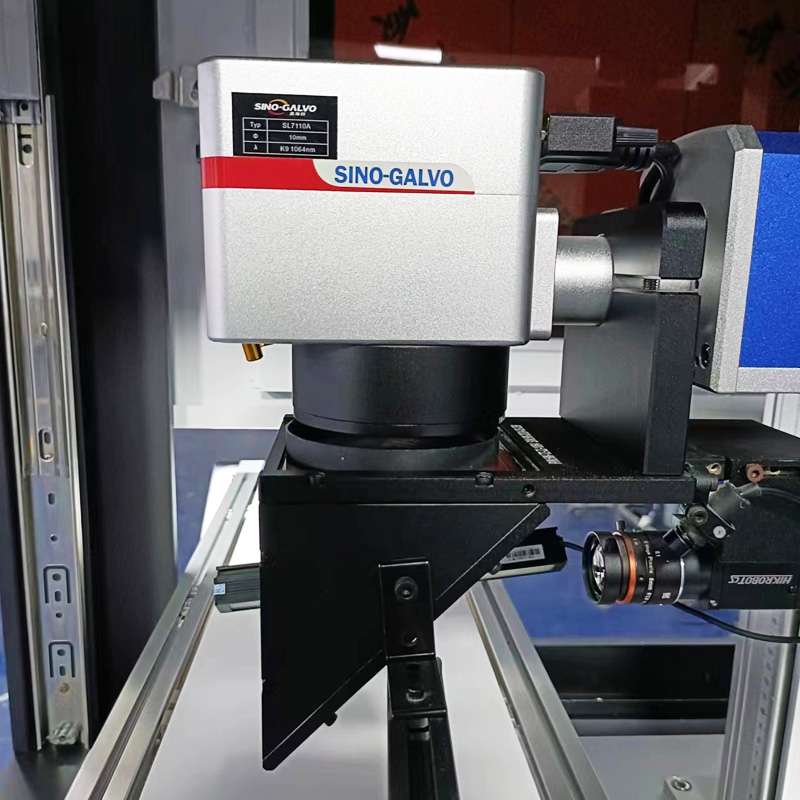

STJ-50F Laser Engraver: Value for Money

The STJ-50F Laser Engraving System is highly performance-oriented and cost-effective; therefore, it is considered a worthy investment for every size of business. Equipped with advanced technology, this model works efficiently in order to minimize operational expenses while providing excellent results for various applications.

With its remarkably low maintenance needs, this is one of the stand-out features of the STJ-50F: durable components and a truly reliable fiber laser source combine to reduce the need for repairs and replacements, thereby promising long-term operation with no downtime and saving costs for repair service.

The energy-efficient design of the machine greatly contributes to cost savings. The STJ-50F consumes less power compared to other traditional methods of engraving, hence reducing electricity bills without compromising performance. Its high-speed operation enables users to finish projects faster, hence improving productivity for quicker turnarounds.

This model's versatility with materials further enhances its cost-effectiveness by accommodating a wide array of engraving needs: from metals to plastics, the STJ-50F saves on the need for multiple machines, reducing the initial investments in equipment. Besides, its precision minimizes material waste, optimizing resource utilization.

With low consumable usages and cheap operational cost, this system is just perfect for those businesses intending to scale up. From mass production to customized projects, the STJ-50F is a balance between affordability and quality, and hence this should be one of the best choices by professionals for high returns on investment.