This laser cutter comes with all the features I would expect. CNC controller is intuitive and easy to use, with all settings visible at a glance. 2000 watt fiber laser is powerful enough to handle all my metal cuts with ease, smooth and clean without burrs. Impressively stable performance, with a full day of continuous cutting without any issues. One thing I have to say, if your budget allows, go for a closed enclosure, after all, the open bed is not a 100% safe option for laser guys. Overall, this is a great buy for the money, and STYLECNC is a reputable brand with dependable options.

Find & Buy Chinese-Made Laser Cutters for Every Budget

A Chinese laser cutter is an affordable laser cutting system made in China with CNC (Computer Number Controlled) controller that adopts laser beam to cut stainless steel, iron, copper, carbon steel, gold, silver, alloy, acrylic, Delrin, films & foils, glass, rubber, wood, plastics, laminates, leather, paper, foam & filters, fabrics, and textiles with low cost, high quality, high speed, and high precision. Chinese laser cutters are used for industrial manufacturing, school education, small business, home business, small shop, home shop and hobbyists. You can find Chinese laser cutting machines everywhere in the world in 2025.

Chinese Laser Cutter List

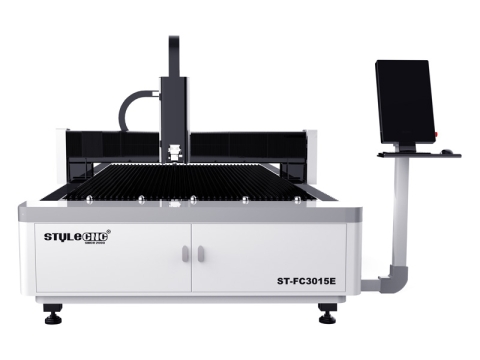

2026 Best Sheet Metal Laser Cutter for Sale (1500W - 6000W)

2026 Top Rated Fiber Laser Cutting Machine for Sale - 2000W

Mini Laser Metal Jewelry Cutter for Silver, Gold, Copper

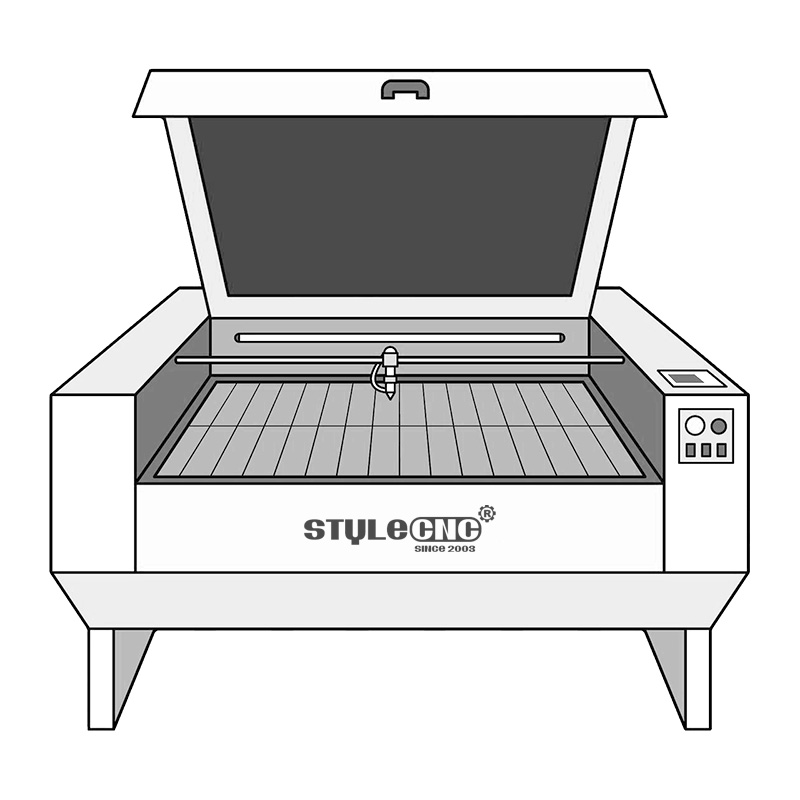

100W Laser Wood Cutter Engraving Machine for Woodworking

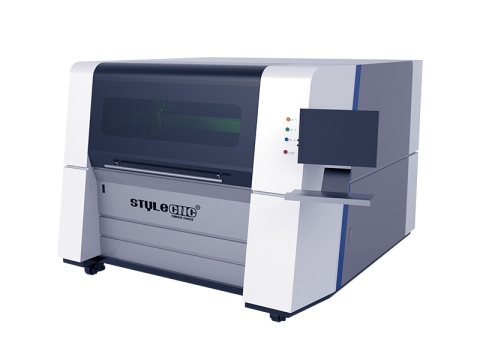

2025 Best Acrylic Laser Cutting Machine for Sale

CNC Laser Cutter With CCD Camera Visual Recognition System

Dual-Head CO2 Laser Cutter for Paper and Cardboard

Industrial 3D Robotic Fiber Laser Cutting Machine for Metal

Entry Level Small Metal Laser Cutter for Beginners

2025 Best-Selling 4x8 Laser Cutter for Plywood & MDF

20000W Ultra High Power Fiber Laser Metal Cutter for Sale

Profitable Mixed CNC Laser Cutter Hybrid Cutting Machine

Pick Your First Laser Cutting Machine Made In China

What is Laser Cutting?

Laser cutting is to concentrate the high-intensity laser beam emitted by the laser generator together, and then irradiate it on the surface of the material. The laser energy is rapidly converted into heat energy, so that the temperature in the irradiated area of the material quickly reaches the melting point and even the boiling point of the material, and the material is exposed to high temperature. Under the guidance of the numerical control system, with the continuous relative movement of the workpiece and the laser beam, there is a continuous interaction between the two. The melted residue is blown away, and the holes are continuously formed into narrow slits to complete laser-cuts.

What is Chinese Laser Cutter?

A Chinese laser cutter is an affordable laser cutting system made in China with CNC (Computer Number Controlled) controller that adopts laser beam to cut metal and non-metal materials with low cost, high quality, high speed, and high precision. Chinese laser cutters are used for industrial manufacturing, school education, small business, home business, small shop, home shop and hobbyists. You can find Chinese laser cutting machines everywhere in the world in 2024.

History

Forty years after Einstein proposed the laser theory, in 1957, Chinese scientists established China's first optical research institute, the Chinese Academy of Sciences (Changchun) Institute of Optics and Precision Instruments and Mechanics ("Institute of Optics and Mechanics" for short). "), under the leadership of the older generation of experts, a group of young scientific and technological workers has grown rapidly, and in a short period of time has gathered an innovative young and middle-aged research team, and put forward a large number of ideas and ideas to improve the brightness, unit color, and coherence of the light source. Experimental program. With the advent of the world's first laser generator in 1960, the research and development of laser generators in China also began to speed up. In 1961, the first ruby laser generator in China was successfully developed, and the first carbon dioxide laser generator was developed in 1965.

In just a few years after the first CO2 laser was developed in China, China's laser technology has developed rapidly. In terms of basic research and key technologies, a series of new concepts, new methods and new technologies have been proposed and implemented, many of which have Ingenuity, and began to gradually use the laser in the field of material cutting.

Since 1978, laser cutting technology has obtained unprecedented opportunities for development, laser technology has achieved unprecedented progress, and a number of internationally advanced achievements have emerged. Laser cutting technology has basically achieved full coverage in the field of material processing in China.

In 2014, the fiber laser cutting machine for metal sheet cutting came out. The laser with only 500W of power that year quickly became the favored object of the market due to the advantages of high cutting efficiency and high processing precision. With the development of laser technology, 1500W and 3000W power gradually appeared. Until 2016, Chinese laser cutter manufacturers broke the limit of 6000W power and launched 8000W fiber laser cutting machine, which opened the competition of laser power. In 2017, the 10,000 watt laser cutting machine came out, and the Chinese fiber laser cutting machine market began to develop into the 10,000 watt era. Until now, 15,000W, 20,000W, 30,000W, 40,000W, and more high laser powers came into being. Moreover, the world's laser generator manufacturers are constantly introducing higher power fiber laser generators.

In 2024, China's laser cutter industry will form an industrial scale concentration. CO2 laser cutting machines are concentrated in Liaocheng, Shandong, and fiber laser cutting machines are concentrated in Jinan, Shandong and Wuhan, Hubei.

Types

Types Based On Table Sizes:

Mini types, Small types, Hobby types, Portable types, Tabletop types, Desktop types, Large format types.

Types Based On Laser Sources:

Fiber laser cutters, CO2 laser cutters.

Types Based On Cutting Materials:

Laser metal cutters, laser wood cutters, laser paper cutters, laser leather cutters, laser fabric cutters, laser acrylic cutters, laser plastic cutters, laser foam cutters.

Materials

Chinese laser cutters can cut stainless steel, iron, copper, carbon steel, gold, silver, alloy, acrylic, Delrin, films & foils, glass, rubber, wood, plastics, laminates, leather, paper, foam & filters, fabrics, and textiles.

Applications

Chinese laser cutting machines are used in industrial manufacturing applications, school education, small businesses, home business, small shop and home shop for Architectural Models, Fablabs & Education, Medical Technology, Smartphones and Laptops, Rubber Stamps Industry, Awards & Trophies, Packaging Design, Giveaways, Sign&Displays Industry, Automotive Industry, Electronics Industry, Signage, Ball bearing, Mechanical engineering, Jewelry Industry, Watches, Barcodes serial numbers, Dataplates Industry, Machining Industry.

Laser Generator

CO2 Laser Generator

Since laser technology was introduced to cut thin metal sheets, CO2 laser generators have dominated the market. The CO2 laser light source requires a lot of energy to excite nitrogen molecules to collide with CO2 molecules (laser gas), prompting them to emit photons, and finally forming a laser beam that can cut through the metal. The molecular activity in the cavity releases light as well as heat, which requires a cooling system to cool the laser gas. This means that more energy is consumed during the cooling process, further reducing energy efficiency.

Fiber Laser Generator

The machine using the fiber laser generator occupies a small area, the laser light source and the cooling system are also smaller; there is no laser gas pipeline, and no need to adjust the lens. The 2000W or 3000W fiber laser light source only needs 50% of the energy consumption of the 4000W or 6000W CO2 laser light source to achieve the same performance, with faster speed, lower energy consumption and less impact on the environment.

The fiber laser generator uses solid-state diodes to pump the molecules in the double-clad ytterbium-doped fiber. The stimulated emission of light passes through the fiber core multiple times, and then the laser is output through the transmission fiber to the focusing head for cutting. Since all intermolecular collisions occur in the fiber, no laser gas is needed, so the energy required is greatly reduced-about one-third of the CO2 laser generator. As the less heat is generated, the volume of the cooler can be reduced accordingly. In short, while achieving the same performance, the overall energy consumption of fiber laser generators is 70% lower than that of CO2 laser generators.

Specifications

| Laser Power | 40W, 50W, 60W, 80W, 100W, 130W, 150W, 280W, 300W, 1000W, 2000W, 4000W, 6000W, 8000W, 10000W, 20000W, 30000W, 40000W |

| Laser Type | Fiber Laser, CO2 Laser |

| Laser Brand | IPG, Raycus, JPT, RECI, MAX |

| Cutting Materials | Metals & Nonmetals |

| Cutting Abilities | Flatbed sheet cut, tube cut, 3D cut |

| Table Sizes | 2x3, 2x4, 4x4, 4x8, 5x10, 6x12 |

| Models | 6040, 9060, 1390, 1325, 3015, 4020 |

| Price Range | $2,600.00 - $300,000.00 |

What Our Customers Say?

Don't take our words as everything. Find out what customers say about our laser cutting machines they have owned or experienced. Why is STYLECNC considered a credible brand and manufacturer to buy a new laser cutting machine? We can talk all day about our quality products, 24/7 excellent customer service and support, as well our 30-day return and refund policy. But wouldn't it be more helpful and relevant for newbies and professionals alike to hear real-life customers experience what it's like to purchase and operate an automatic computer-controlled machine tool from us? We think so too, which is why we've collected tons of genuine feedback to help bring transparency to our unique buying process in-depth. STYLECNC guarantees that all customer reviews are real evaluations from those who have purchased and used our products or services.