This lathe came 100% assembled from STYLECNC, plug and play, and the first thing I did was just rough in a table leg for fun. The CNC controller made it super easy to play with, and the woodturning was smooth and clean, far exceeding my expectations.

Pros: Heavy-duty cast iron bed makes it sturdy and durable. Fully automated CNC control system frees your hands, improves productivity and saves manufacturing costs.

Cons: Must go with the auto-feeder option (about $1,000) if you try to take off too much wood blanks at once, as well as a software upgrade.

All in all, It's a beginner-friendly lathe machine for getting started with woodworking automation. Best lathe ever and so far STYLECNC hasn't let me down.

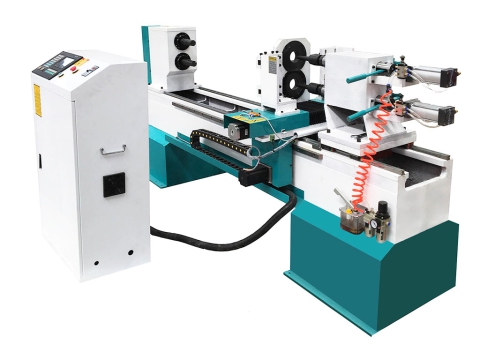

Industrial CNC Wood Lathe for Table Legs & Stair Balusters

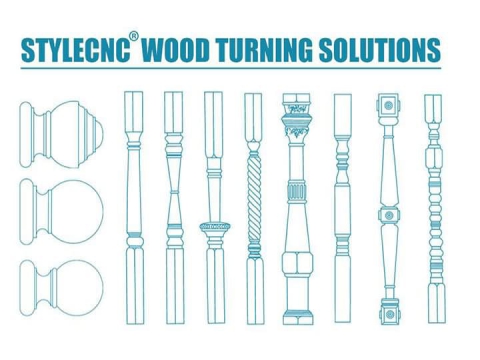

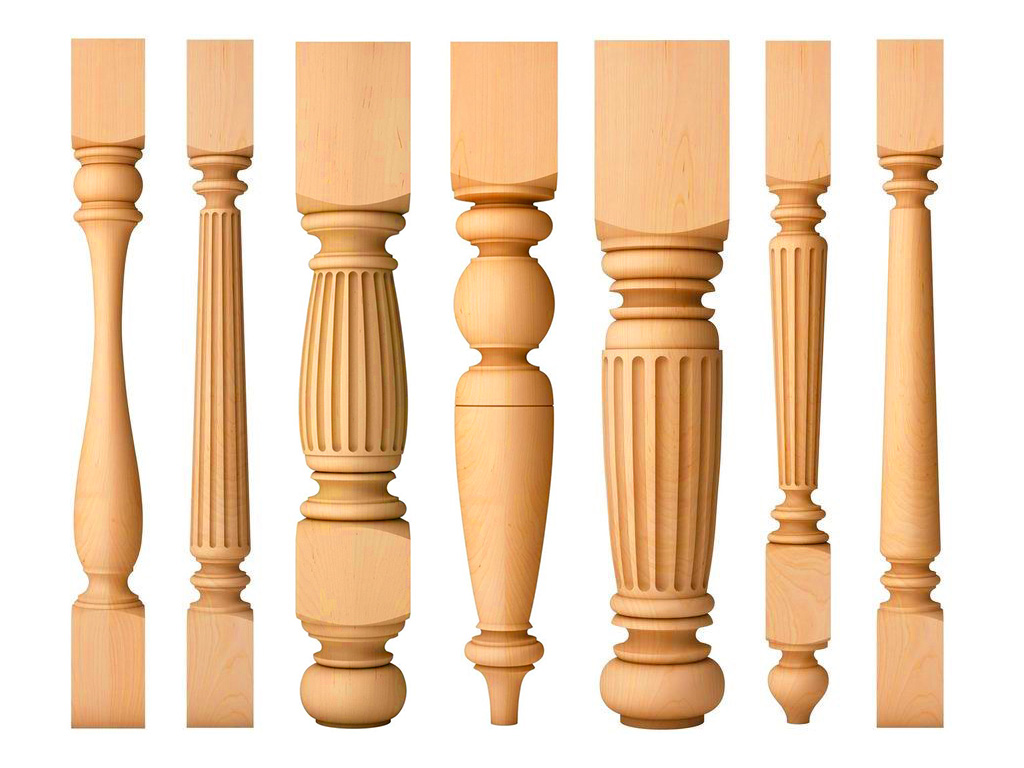

Industrial wood lathe machine with CNC controller is a full size automatic woodworking lathe for turning table legs, chair legs, sofa legs and feet, furniture legs, stair spindles, balusters, newel posts, railing posts, pillars and banisters.

- Brand - STYLECNC

- Model - STL1530-S

- Maker - Jinan Style Machinery Co., Ltd.

- Category - CNC Wood Turning Lathe Machine

- 360 Units in Stock Available for Sale Every Month

- Meeting CE Standards in Terms of Quality & Safety

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- 30-Day Money Back Guarantee for Your Purchase

- Free Lifetime Technical Support for End-Users & Dealers

- Online (PayPal, Alibaba) / Offline (T/T, Debit & Credit Cards)

- Global Logistics and International Shipping To Anywhere

Are you still looking forward to how to make personalized table legs? Are you struggling with what tools to choose for making stair railings? A wood lathe makes it easy to make modern furniture legs, stair spindles, and newel posts. A CNC lathe even automates the manufacturing of wooden table legs and stair balusters.

What is a CNC Wood Lathe?

A CNC wood lathe is an automatic turning machine capable of shaping various styles of timber furniture legs such as table legs, sofa legs and feet and chair legs, as well as wood balusters, stair spindles, stair railing posts, newel posts, pillars and banisters made of hardwoods such as ash, hemlock, oak, maple, pine, mahogany, walnut, and cherry. It's user-friendly and easy to use for beginners and professionals. Just need to design a template, and you can start turning your lumber of choice with an automatic lathe, you can get a fine turning of table leg or stair baluster in minutes.

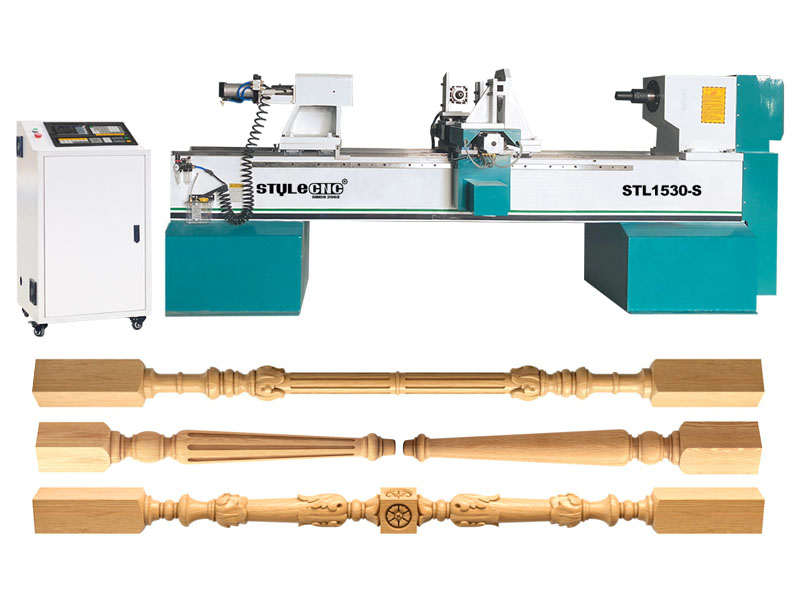

In addition, the STL1530-S automatic wood lathe comes with an additional feature of milling & carving wooden balusters and furniture legs with decorative elements, which can be personalized with traditional and contemporary patterns to fit your home decor style.

Applications of Industrial CNC Lathe for Wood Stair Spindles and Table Legs

The STL1530-S industrial CNC wood lathe is ideal for crafting high-quality, detailed wood products, particularly in furniture and staircase manufacturing. Its precision and versatility make it a go-to machine for turning wooden components like table legs, spindles, and decorative posts.

For furniture production, the CNC lathe creates various types of legs—dining table legs, end table legs, chair legs, and bar stool legs. This ability allows furniture makers to achieve consistent, accurate designs for any style or aesthetic. Beyond table and chair legs, the machine can also shape sofa feet, bun feet, and complex chair stretchers.

In staircase production, the CNC lathe efficiently turns staircase columns, stair spindles, balusters, and newel posts. These elements are essential for staircases in both homes and commercial buildings, where uniformity and detailed craftsmanship are required. The STL1530-S can also produce stair railing posts, stair pillars, and banisters, enabling seamless integration across different staircase components.

Additionally, this lathe handles more unique designs like Roman columns, baseball bats, and custom items like bed rails, lamp posts, and pool cues. Its versatility extends to smaller projects too, such as timber bowls, vases, pens, cups, and holders, making it perfect for custom woodwork and decorative items.

Technical Parameters of Industrial CNC Wood Lathe for Table Legs and Stair Balusters

| Brand | STYLECNC |

| Model | STL1530-S |

| Max turning length | 1500mm |

| Max turning diameter | 300mm |

| Axis and Blades | single axis, 2 blades |

| Maximum feed rate | 2000mm/min |

| Minimum setting unit | 0.1mm |

| Spindle motor power | 4KW |

| Power supply | AC380V/50hZ (AC220V for option) |

| Overall dimensions | 3290*1270*1540mm |

| Weight | 1600kg |

| Price Range | $7,180.00 - $7,680.00 |

Features of Industrial CNC Lathe Machine for Wooden Table Legs and Newel Posts

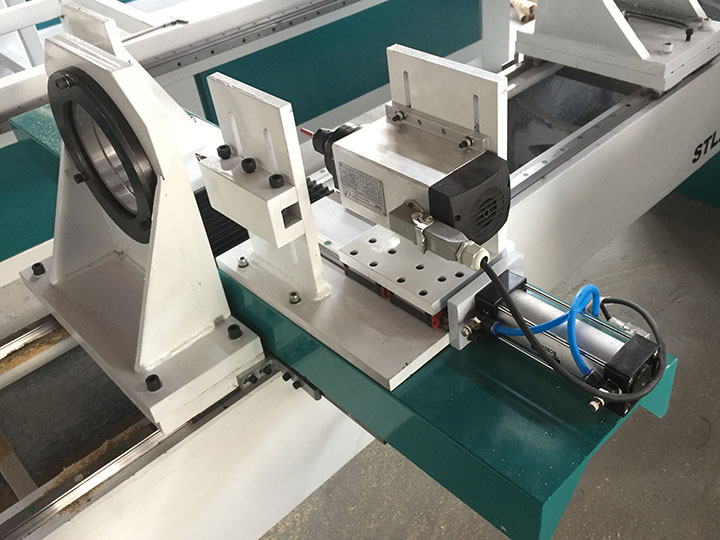

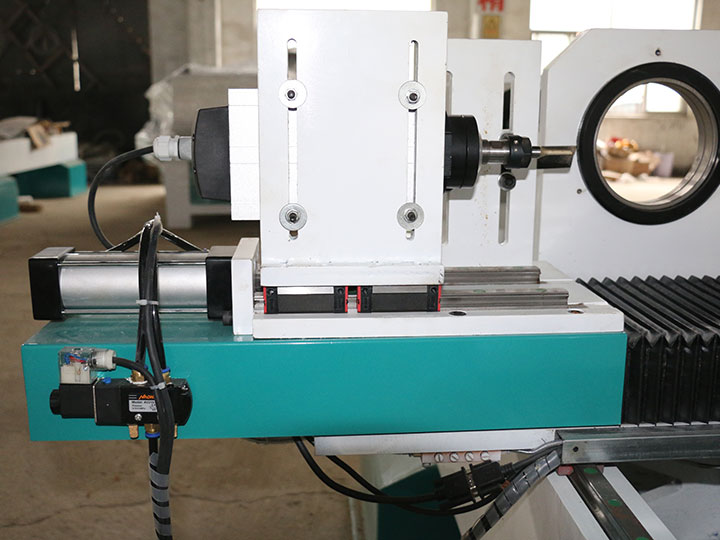

One thimble, one chuck, and one backlash, it can be upgraded with two chucks and two backlash so that it can complete the workpiece simultaneously.

Heavy-duty with good stability to avoid shaking when the spindle rotates with high speed for the big sizes workpiece process, and the main spindle speed can be adjusted through the frequency converter.

Easy operation, we can draw by Coredraw, Artcam, AutoCAD, and other software, and the control directly by the CNC cabinet computer (Industrial PC configuration) or transfer the files to the machine by USB (DSP handle configuration).

High-frequency inverter with high stability.

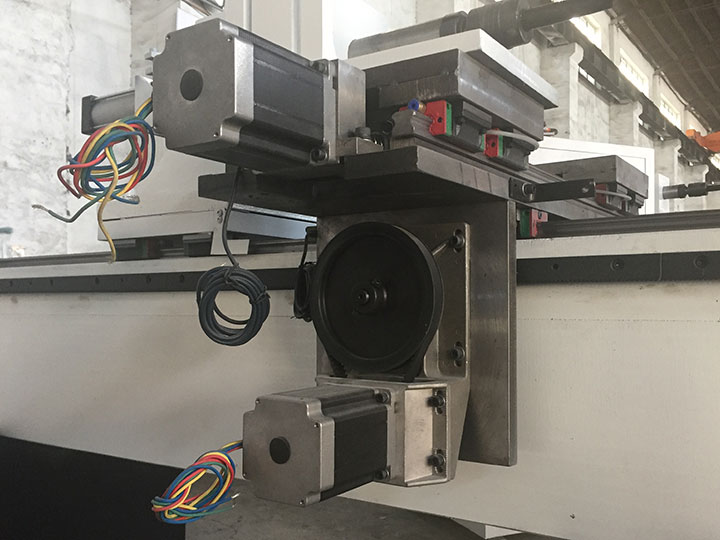

The industrial CNC wood lathe machine comes with Taiwan TBI ball screw and Taiwan Hiwin square rail with high transmitting precision and longevity, big module helical/diagonal rack with high precision and durable.

High accuracy stepper motor, after program calculating, guarantee the exact turning size.

Industrial Wood Lathe Turning Table Leg and Stair Baluster Projects

CNC Wood Lathe vs. Traditional Wood Lathe

For anyone working with table legs, balusters, or detailed wood designs, it's essential to know the differences between CNC and traditional wood lathes. Below is a comparison to help you decide which tool suits your needs best.

| CNC Wood Lathe | Traditional Wood Lathe |

| Highly precise with consistent results on each piece. | Depends on operator skill; can vary piece to piece. |

| Automated operation reduces manual labor. | Manual operation requires constant user involvement. |

| Faster production speed, ideal for bulk projects. | Slower, as each piece is shaped individually. |

| Easily creates intricate, repetitive designs. | Complex designs are more challenging to replicate. |

| Less hands-on skill needed; software does the work. | Requires advanced skills for consistent quality. |

This table highlights the main contrasts in operation, precision, and user involvement between CNC and traditional lathes, helping woodworkers choose the best option for their projects.

Maintenance Tips for CNC Wood Lathes in Industrial Settings

Regular maintenance is key for keeping CNC wood lathes in top shape, especially in busy industrial environments. Proper care can extend the life of your machine, reduce downtime, and ensure smooth, precise operation on every project.

• Clean the Machine Daily: Dust and debris can quickly build up during operations. Wipe down surfaces daily and clear any wood shavings to keep the machine running smoothly and prevent parts from getting clogged.

• Lubricate Moving Parts: Regularly check and oil all moving parts, including the bearings, spindles, and gears. Proper lubrication reduces friction and extends the lifespan of these components.

• Inspect the Tooling: Blunt or damaged tools can impact accuracy and quality. Inspect the cutting tools frequently for wear and replace them as needed to maintain precision in every job.

• Check Electrical Connections: Industrial settings can be rough on machinery, and vibrations can loosen connections. Inspect cables and connectors regularly, ensuring that everything is secure and functional.

• Monitor Software and Calibration: Make sure the software is up-to-date and perform calibration checks regularly. This helps the lathe maintain precise measurements and smooth operation during complex tasks.

FAQS for CNC Wood Balusters and Table Legs Turning Lathe Machine

What types of wood can a CNC lathe turn to make stair spindles?

Almost all hardwoods such as ash, oak, hemlock, maple, pine, walnut, mahogany, cedar, hemlock, redwood, poplar, and cherry stand out as popular options for CNC lathe turning to make stair spindles and wood balusters, and newel posts. Of all the woods, cedar, redwood, and poplar are better woods for exterior use than others, as they come with natural weather resistance.

Is a CNC wood lathe hard to learn to make furniture legs for beginners?

Whether you are new to turning or you are an experienced woodworker & carpenter, you can easily operate a CNC wood lathe machine to make dining table legs, end table legs, chair legs, bar stool legs, sofa legs, and other furniture legs because it is a fully automatic turner with almost no manual intervention. The only difficulty is that you need to have some knowledge of CAD/CAM software.

Can a CNC wood turner copy and mass-produce table legs and stair balusters?

An automatic wood lathe with a CNC controller can create two wooden posts at once using a dual-spindle turning machine, and three timber pillars at a time using a three-spindle turner, enabling copy turning and mass production of table legs and stair balusters for industrial manufacturing.

How much does a CNC turner cost for making wooden posts?

An entry-level CNC wood lathe for making wood posts starts at $5,880, and can go up to $7,180 featuring with a milling spindle. A copy lathe with twin spindles costs from $6,380 to $8,280, and a three-spindle industrial turner for timber pillars ranges from $6,980 to $9,080. All prices depend on your machine configuration and additional options.

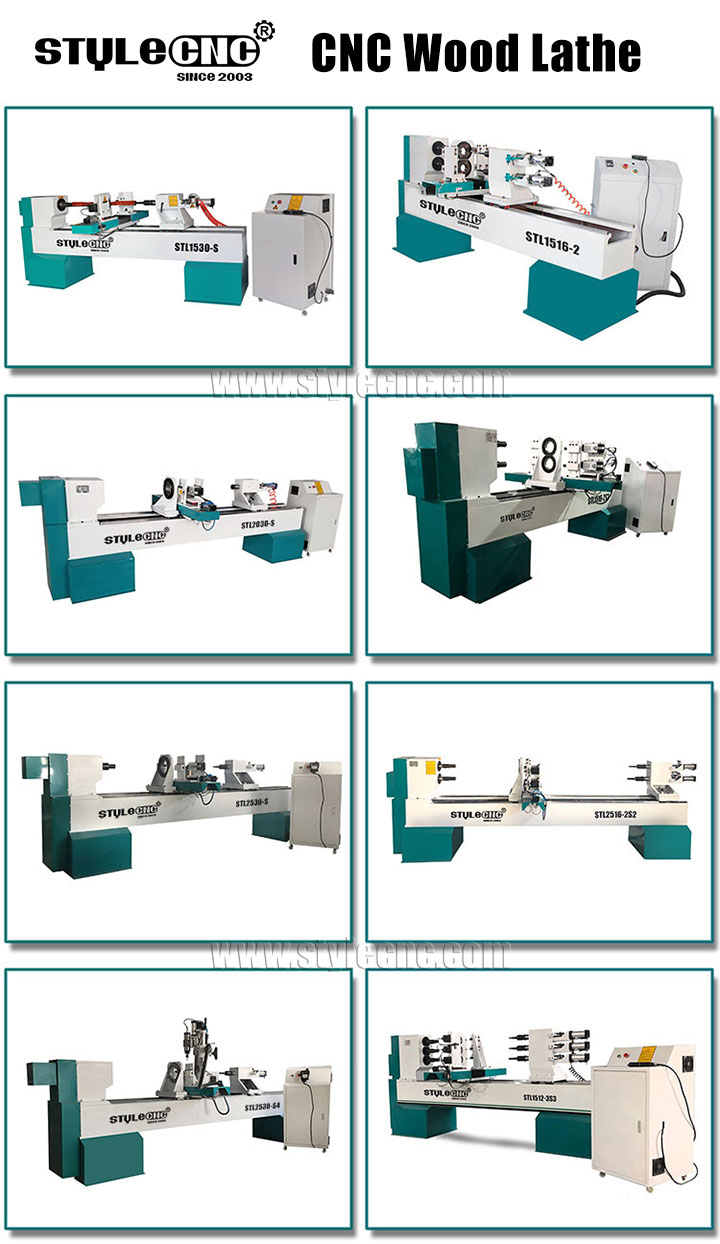

See More CNC Wood Lathe Machines for Stair Balusters and Table Legs

Stein Lichner

Ivan Kornilenko

Этот автоматический токарный станок был хорошо упакован, и его было легко собрать. Я новичок в ЧПУ, поэтому нам нужно научиться настраивать и запускать программное обеспечение. Я пытался перевернуть некоторые ножки стола, и это отлично сработало, и я продолжу переворачивать другие проекты. Этот токарный станок по дереву сделал именно то, о чем я его прошу. Пока я очень доволен своей покупкой.

Syed Salman

We finally delivered the wood lathe machines to customers and now they are working well. We are ready to place a new order with STYLECNC. Our client like red. So they are very happy because the machine can customize colors.

Mauro Silva

Received the wood lathe quickly in Denmark. There was no defect in the machine tool. Did the job a lot faster than ordinary manual lathes. Very satisfied with this unit and delivery. Thanks.

Jack Keezer

The lathe machine has been received in 20 days, no complex assembly. I have used it several times, everything seems well balanced and no vibration since we got it and it has been fantastic. I would be proud to show it off to my friends and partners.

Graham Michael

Love everything about the woodworking lathe, it seems sturdy and has no doubt. I have used this machine many times and found it to work great with no problems. Glad I made the purchase.