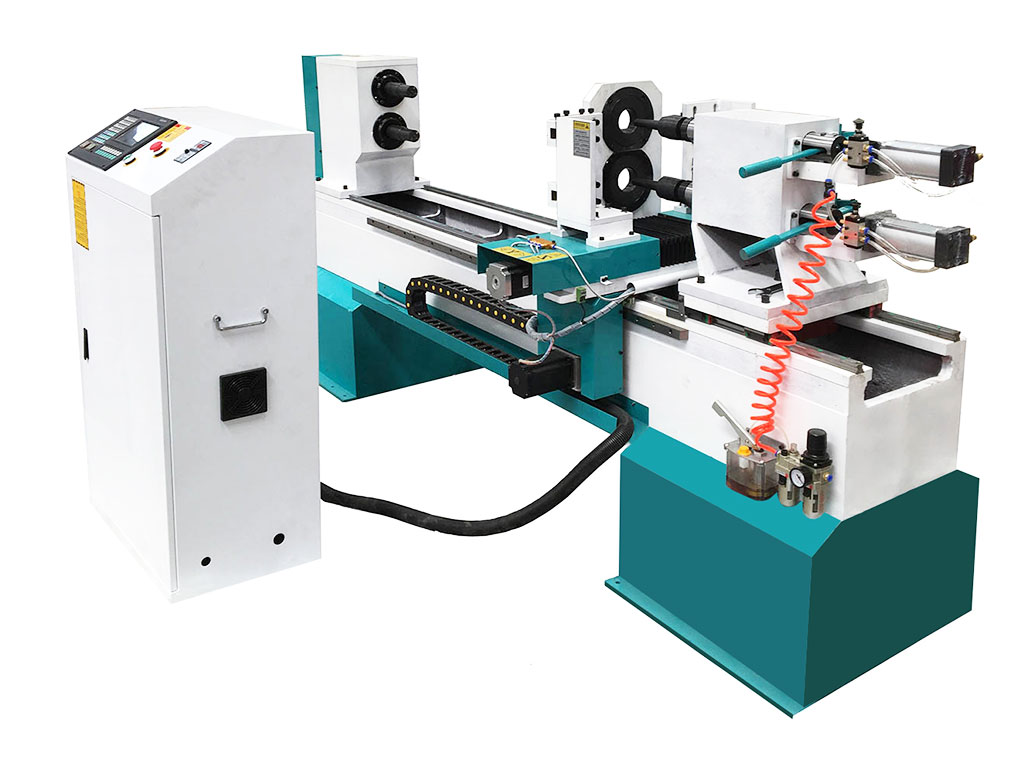

CNC wood turning lathe machine is a kind of mechanical woodworking machinery with high precision, high efficiency, when you are troubled with system errors or random errors in the use of the machine, start to learn the solutions for troubleshooting.

1. CNC wood lathe machine will not start.

a. Check that the start switch is being pressed full in.

b. Check that the red stop switch is fully out.

c. Check that the electrical power cord is plugged into the power outlet.

d. Check that the electrical supply is on (reset the breaker).

e. With the power disconnected from the machine, check that the wiring to the plug is correct. Check that the rubber insulation is stripped enough and is not causing a bad connection. Check that all the screws are tight.

2. Wood CNC lathe machine will not stop.

This is a very rare occurrence, as the machine is designed to fail-safe. If it should occur and you cannot fix the fault, seek professional assistance. The machine must be disconnected from the power and never run until the fault has been rectified.

Internal breaker faulty. Replace the breaker.

3. The motor tries to start but will not turn.

a. With the power disconnected from the machine, try to turn the spindle by hand. If the spindle will not turn, check the reason for the jamming.

b. Motor faulty. Replace the motor.

c. Spindle was run without coolant. Replace the motor.

4. Motor overheats.

The motor is designed to run hot, but should it overheat, it has an internal thermal overload protector that will shut it down until the motor has cooled, and then it will reset automatically. If the motor overheats, wait until it has cooled and restart. If the motor shuts down consistently, check for the reason. Typical reasons are dull cutting tools, no water in the coolant tank, blockage in the coolant pipe and excessive ambient temperature.

5. The spindle slows down during a cut.

a. Dull cutting tools. Replace the tool or have it re-sharpened.

b. Feeding the wood too fast. Slow down the feed rate.

6. Test error detection system, including the following aspects.

a. The manufacturing error of measurement sensor and its application in machine tools installation error caused by the measurement error of the sensor system itself.

b. Due to the error of machine tool parts and institutions as well as in the use of the deformation causes measurement error of sensors.

7. Interference error.

Interference caused by the change of the environment and the operation condition of random error.

8. Machining system error.

Cutting load caused by the deformation, including the machine tool, cutting tool, workpiece and fixture deformation caused by the error. This error is also known as "dao", which caused the shape distortion of machining parts, especially when machining thin walled workpiece or use thin tool, the error is more serious.

9. The vibration of the machine tool error when machining.

Because of the flexibility of the process and the process variable, its running state has the possibility of a larger, fall into unstable region, thus draw strong flutter. Leads to the deterioration of the machining surface quality and geometry shape error. Re-level the woodworking lathe machine, ensuring that it has no movement.

10. The original manufacturing error.

Refers to the parts of machine CNC woodworking lathe work on the surface of the geometry shape, surface quality, the position error between error caused by the movement, is the main reason for the CNC machine tool geometric error.

11. Error control system.

Including CNC woodworking lathe axis servo error (contour following error), CNC interpolation error.

12. The thermal deformation error.

Due to equipment internal heat source and environmental thermal disturbance of the structure of machine tool thermal deformation error.

The above mentioned are the main reasons for the CNC wood lathe errors, the main reasons for causing errors can be divided into two categories according to the characteristics and nature of errors: the system errors and random errors. System error of CNC woodworking lathe machine is intrinsic to the machine tool error, repeatability, geometric error of CNC lathe machine tools is the main component, also has the repeatability. Using this feature, it can be to "offline" measurement, can use "off-line testing - open loop compensation" technology to be revised and compensation, make it decreases, and achieve the goal of precision machine tools to strengthen. Above is the CNC wood lathe to produce in combination with the analysis of the causes of error, according to the situation of your equipment.