What Are CNC Router Bits and Tools?

The CNC router bits are the cutting components of CNC router machines. They are designed to shape, cut, or engrave various materials with precision. They come in different shapes, sizes, and materials to suit diverse applications and materials like wood, metal, plastic, or stone.

Router bits can also be made from materials like carbide or high-speed steel. The carbide bits are more durable and designed for the harder materials, while the steel bits are quite a lot cheaper for softer materials. Each bit has its own purpose: engraving, profiling, or cutting through materials.

The right CNC router tools must be chosen in order to have high-quality results. Different applications require specific types of bits; otherwise, the wrong bit would either perform poorly or cause damage to the material. Proper selection ensures efficiency and extends the life span of the cutting tool.

CNC Router Tools & Bits

CNC router tools usually come in three different materials, that are: High-Speed Steel (HSS), Solid Carbide, and Diamond Tooling. Before starting the guide, let us learn the CNC router tool geometry.

Flutes: In CNC routing, flutes refer to the cutting edges or channels on a router bit. This is the part of the tool that augers out the cut material. The number of flutes on a cutter is important in determining the chip load.

Shank: The shank is the part of the tool that is held by the tool holder. It is the part of the tool that has no evidence of machining. The shank must be kept free of contamination, oxidation, and scratching.

Cutting Length: The length of the cut means the effective cutting depth of the tool or how deep the router bit can cut into the material.

Cutting Diameter: This is the diameter or the width of the cut that the tool will produce.

Now, let's list all types of router bits and tools.

3D Burin CNC Tools

3D burin CNC tools are specialized router bits designed for creating intricate three-dimensional shapes and contours in various materials using a CNC machine. It has high concentricity and, a sharp edge. It is recommended to do precision 3D carving processing.

Edge CNC Router Bits

Edge CNC router bits are particular cutting tools designed for creating precise edges and profiles on workpieces using a CNC router machine. It is High-density MDF, and wood is recommended to use edge CNC router bits.

Double Edge Straight Slot CNC Bits

Double-edge straight slot CNC bits are cutting tools made to create accurate straight slots or grooves in workpieces using a CNC router machine. The multilayer board and plywood processing are recommended using double-edged straight slot CNC bits.

Round Bottom CNC Tools

Round-bottom CNC tools are cutting tools used in CNC machining processes. These tools have a rounded cutting edge at the tip, which allows them to create contoured or sculpted surfaces with smooth finishes. Precision small anaglyph processing is recommended using round bottom tools.

Double Blades Rowed Spiral Cutter

MDF cutting processing (advertising mold opening) is recommended to use a double-blade rowed spiral cutter. It has two high-capacity chip grooves, and a double-edge design, both of them contain a decent chip removal function, and can achieve a good balance tool. In processing high MDF, there is no black and no cap smoke. Moreover, it gives a lifelong service.

Single Blade Special Aluminum CNC Bits

The aluminum plate cutting process is recommended using single-blade special aluminum CNC bits. A non-stick knife is used in the processing, as well as quick speed and high efficiency.

Single and Double Blade Up-Down Cutter

For the double sides burr-free cutting process, it is recommended to use a single-blade and double-blade up-down cutter.

Single and Double Blade Straight Flute Sharp Cutter

In metal sculpture processing, use single and double-blade straight flutes and a sharp knife.

Single Blade Spiral CNC Cutter

A Single Blade Spiral CNC Cutter is a type of cutting tool particularly used in woodworking applications. In acrylic cutting processing, you can use this cutter.

The characteristics of this cutter when processing are smokeless and odorless, fast speed, high efficiency, non-stick crumbs, and environmentally friendly. The special manufacturing process ensures that processing acrylic does not burst broken, fine grain, or even cutter grain. Lastly, the surface is bright, clean, and level off.

Double three-blade spiral CNC cutter

When you want to achieve a frosted effect in the machining surface, it is recommended to use a double three-blade spiral CNC cutter.

Diamond Graver

Diamond Graver refers to a cutting tool used in engraving, jewelry making, and precision machining. Acrylic mirror engraving processing is recommended to use diamond graver.

Multi-Stripes CNC Router Tools

Rough machining particleboard is recommended to use multi-stripes CNC tools.

Tungsten Steel CNC Router Tools

When it comes to the metal mold processing and milling cutter, it is recommended to use a tungsten steel CNC cutter. The cutter has a violet-black hardened titanium plating surface.

Single Blade Helical Ball End Mill

For cork, density board, original wood, PVC, and acrylic large deep anaglyph processing is recommended to use single blade helical ball end mill.

Incised Cutter

When employing incised cutter processing techniques, the surface of the finished product will be smooth and without any rough edges or protrusions (burr). It also ensures that it does not develop any warping during the cutting or machining operation.

Finally, these are the detailed guide to router bits. CNC tools play a crucial role in modern manufacturing and machining processes, offering unparalleled precision, efficiency, and versatility. Hope this guide will help you. Moreover, if you have any confusion or queries, feel free to ask us.

Maintaining CNC Router Bits for Optimal Performance

Proper maintenance of CNC router bits is essential for precise cuts and a longer lifespan. Regular care reduces wear and ensures smooth operation.

Clean After Each Use

Dust, debris, and resin build up on router bits after use.

Clean the bits using a soft brush or cleaning solution. This helps maintain sharpness and prevents overheating during the next use.

Inspect for Wear and Damage

Regularly check bits for signs of dullness, chips, or cracks.

Worn bits can compromise accuracy and damage materials. Replace damaged bits promptly to maintain quality and safety.

Store Properly

Keep router bits in a dry, organized container.

Avoid stacking or dropping them, as this can cause damage. Proper storage extends their usability and prevents accidents.

Common Mistakes to Avoid with CNC Router Tools

Mistakes with CNC router tools can affect project quality and machine performance. Understanding these pitfalls helps you avoid costly errors.

Using the Wrong Bit for the Material

Each material requires specific bits for optimal performance.

Using a wood bit for stone or metal leads to damage and poor results. Match bits to the material and task for precision and efficiency.

Overloading the CNC Machine

Pushing the machine too hard can dull bits and strain the motor.

Maintain appropriate feed rates and avoid cutting depths that exceed the machine’s capability.

Skipping Maintenance

Dirty or dull bits produce uneven cuts and overheat quickly.

Regular cleaning and inspection are vital to maintain bit performance and project quality.

FAQs

What does CNC stand for?

CNC stands for Computer Numerical Control.

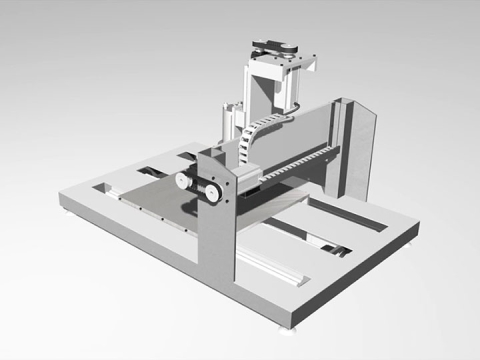

What is a CNC router?

A CNC router is a computer-controlled cutting machine used for cutting various materials, such as wood, plastic, metal, foam, and other composites.

How many materials do CNC router tools come in?

Typically, a CNC router comes with three materials.

What are the three materials that CNC router tools contain?

The three materials of the CNC router are - High-Speed Steel (HSS), Solid Carbide, and Diamond Tooling.